In short, a vacuum tube furnace provides an exceptionally pure, controllable, and non-reactive environment for high-temperature material processing. Its primary benefit is the ability to remove atmospheric gases like oxygen and nitrogen, which prevents oxidation and other unwanted chemical reactions. This capability, combined with precise temperature uniformity, enables the creation of materials with superior purity and enhanced mechanical properties.

The true value of a vacuum tube furnace is not just its ability to get hot, but its power to create a chemically "clean room" for your materials. By removing the reactive atmosphere, you gain precise control over the material's final composition and structure, achieving results impossible in open air.

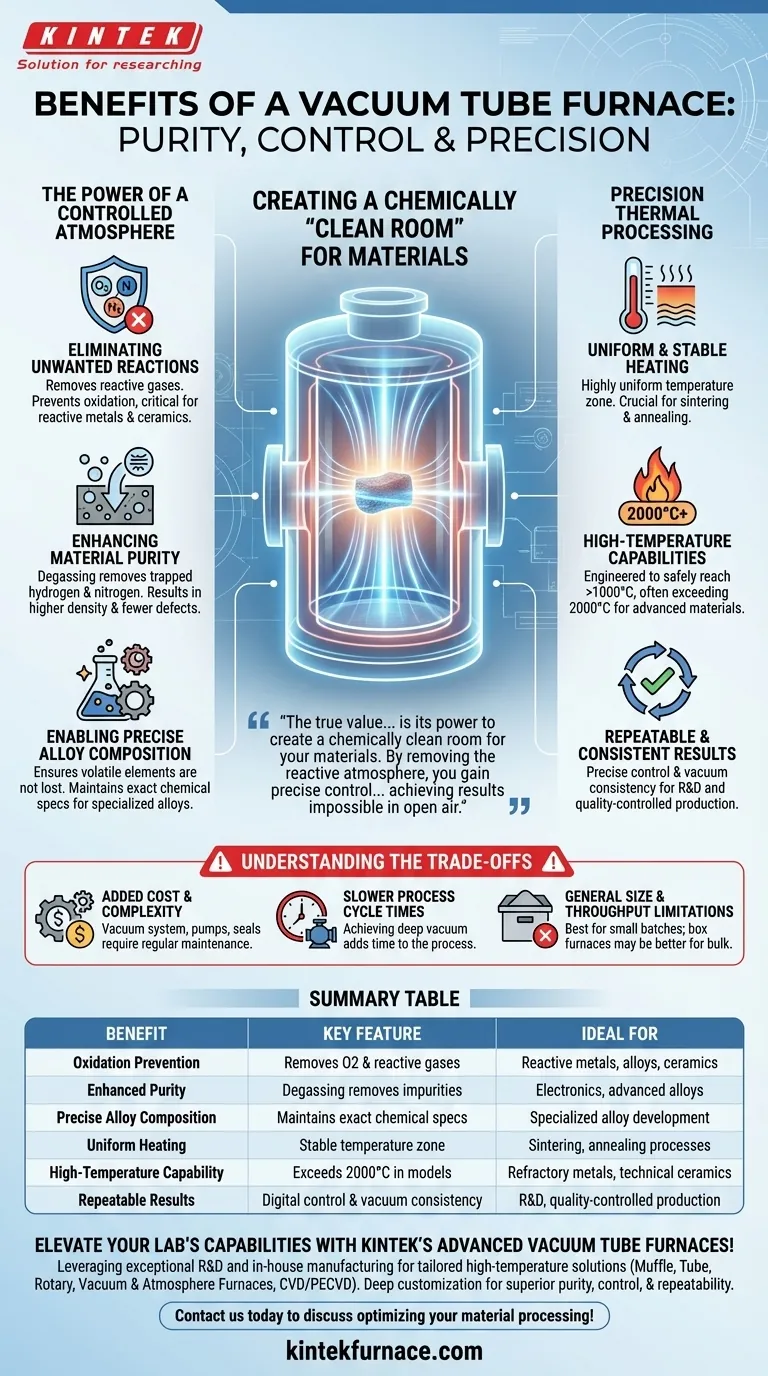

The Power of a Controlled Atmosphere

The defining feature of a vacuum tube furnace is the vacuum itself. Pulling a vacuum creates an environment fundamentally different from a standard atmospheric furnace, which directly impacts material integrity.

Eliminating Unwanted Reactions

Nearly all high-temperature processes in a normal atmosphere are subject to oxidation. The vacuum pump system actively removes oxygen and other reactive gases from the furnace chamber.

This prevents the formation of undesirable oxide layers on a material's surface, which is critical when working with reactive metals, alloys, and certain ceramics.

Enhancing Material Purity

A vacuum environment is highly effective at degassing, or removing trapped impurities from within a material.

As the material is heated, dissolved gases like hydrogen and nitrogen are drawn out, leading to a final product with higher density, fewer defects, and greater overall purity. This is essential for applications in electronics and advanced alloys.

Enabling Precise Alloy Composition

When creating specialized alloys, a vacuum ensures that volatile or reactive elements are not lost to oxidation. This allows for the precise manipulation and maintenance of the material's chemical composition.

The result is an alloy that meets exact specifications with superior consistency from batch to batch.

Precision Thermal Processing

While the vacuum is critical, the furnace's thermal performance is what enables the transformation. Vacuum tube furnaces are designed for exceptional temperature management.

Uniform and Stable Heating

Tube furnaces naturally create a highly uniform temperature zone in the center of the tube, with cooler zones at the ends. This predictable gradient ensures that the sample receives consistent heat across its entire length.

This uniformity is crucial for processes like sintering and annealing, where even small temperature variations can lead to inconsistent grain growth, internal stresses, or incomplete reactions.

High-Temperature Capabilities

Many advanced materials, including refractory metals (like tungsten and molybdenum) and technical ceramics, require processing temperatures well above 1000°C.

Vacuum tube furnaces are engineered to safely reach and maintain these extreme temperatures, often exceeding 2000°C in specialized models, enabling a wide range of advanced material synthesis.

Repeatable and Consistent Results

The combination of a controlled atmosphere and precise digital temperature regulation makes processes highly repeatable. Once a processing profile is established, a vacuum tube furnace can execute it consistently, which is vital for both scientific research and quality-controlled production.

Understanding the Trade-offs

While powerful, a vacuum tube furnace is a specialized tool with specific considerations. It is not the optimal choice for every heating application.

Added Cost and Complexity

The vacuum system—including pumps, seals, and gauges—adds significant cost and mechanical complexity compared to a simple atmospheric tube furnace. These components require regular maintenance to ensure a reliable vacuum seal.

Slower Process Cycle Times

Achieving a deep vacuum takes time. The pump-down and potential back-filling or venting phases add significant duration to the overall process cycle compared to simply heating and cooling in an atmospheric furnace.

General Size and Throughput Limitations

Tube furnaces are best suited for processing smaller batches or continuously processing materials with a small cross-section. For bulk treatment of large or irregularly shaped parts, a vacuum box furnace may be a more practical solution.

Making the Right Choice for Your Process

Selecting the right furnace depends entirely on your material and desired outcome.

- If your primary focus is material purity or processing reactive metals: A vacuum tube furnace is essential to prevent oxidation and remove contaminants.

- If your primary focus is process repeatability for R&D: The precise atmospheric and thermal control offers unparalleled consistency for developing and testing new materials.

- If your primary focus is simple heat treatment of non-reactive materials: A standard atmospheric tube or box furnace is likely a more cost-effective and straightforward solution.

Ultimately, choosing a vacuum tube furnace is a decision to prioritize material integrity and process control above all else.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Oxidation Prevention | Removes oxygen and reactive gases | Reactive metals, alloys, ceramics |

| Enhanced Purity | Degassing removes trapped impurities | Electronics, advanced alloys |

| Precise Alloy Composition | Maintains exact chemical specs | Specialized alloy development |

| Uniform Heating | Stable temperature zone | Sintering, annealing processes |

| High-Temperature Capability | Exceeds 2000°C in models | Refractory metals, technical ceramics |

| Repeatable Results | Digital control and vacuum consistency | R&D, quality-controlled production |

Elevate your lab's capabilities with KINTEK's advanced vacuum tube furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for superior purity, control, and repeatability. Contact us today to discuss how our furnaces can optimize your material processing and drive innovation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis