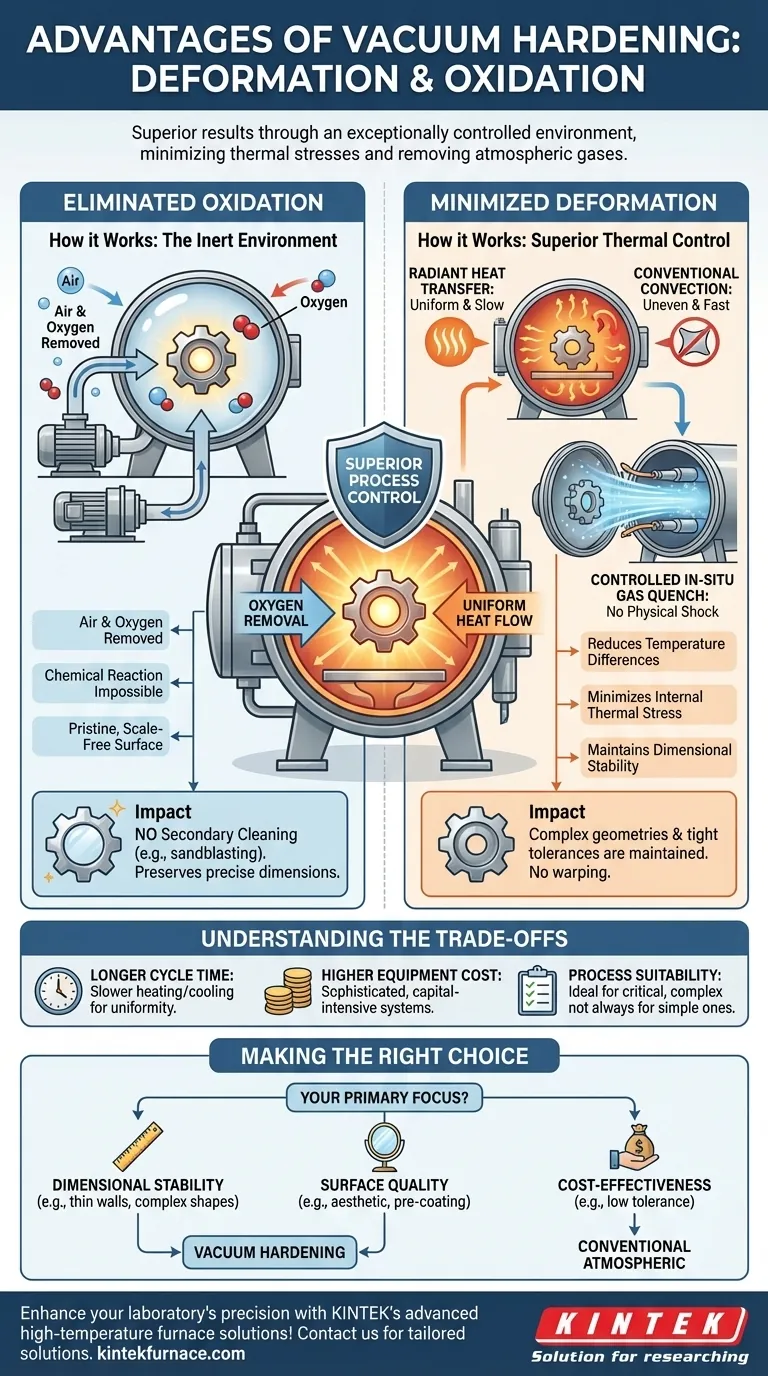

In terms of deformation and oxidation, vacuum hardening offers superior results by providing an exceptionally controlled environment. The process virtually eliminates oxidation by removing atmospheric gases, and it minimizes deformation by ensuring slow, uniform heating and cooling, which drastically reduces the internal thermal stresses that cause parts to warp.

The core advantage of vacuum hardening lies in its fundamental physics. By removing oxygen, it prevents surface chemical reactions (oxidation). By relying on radiant heat transfer, it minimizes temperature differences within the part, which is the primary driver of distortion and warping during heat treatment.

How Vacuum Hardening Eliminates Oxidation

The most apparent benefit of processing parts in a vacuum furnace is the complete prevention of surface oxidation and decarburization.

The Principle of the Inert Environment

A vacuum furnace works by using powerful pumps to remove air—and specifically oxygen—from the heating chamber before the temperature rises.

Because oxidation is a chemical reaction between the hot metal surface and oxygen, removing the oxygen makes the reaction impossible. The part is heated, soaked, and cooled in a chemically inert environment.

The Impact on Surface Integrity

This lack of reaction results in parts emerging from the furnace with a bright, clean, and scale-free surface.

This pristine finish often eliminates the need for secondary cleaning operations like sandblasting, grinding, or chemical pickling, saving time and cost while preserving the part's precise surface dimensions.

Why Vacuum Hardening Minimizes Deformation

Deformation, such as warping or dimensional change, is a major concern in heat treatment. Vacuum hardening mitigates this risk through superior thermal control.

The Root Cause: Thermal Stress

Most deformation is caused by thermal stress. This occurs when one part of a component heats or cools faster than another, creating internal forces that pull and push the material out of shape.

Uniform Heating via Radiation

In a conventional furnace, heat is transferred mainly by convection (hot air currents), which can heat a part's surface and thin sections much faster than its core.

In a vacuum, heat is transferred primarily through thermal radiation. This method heats the part more slowly and uniformly, significantly reducing the temperature difference between the surface and the core. This uniform heating minimizes the buildup of internal stress.

Controlled Cooling (Quenching)

After heating, the quenching (cooling) stage is also highly controlled. Instead of dropping the hot component into a liquid like oil or water, vacuum quenching often uses a high-pressure blast of inert gas.

Crucially, the part can be cooled in-situ (in its original position), avoiding the physical shock and rapid, uneven temperature change associated with moving and submerging a component. This slow, controlled quench is the final step in preventing distortion.

Understanding the Trade-offs

While vacuum hardening offers clear advantages, it is essential to recognize its operational context and limitations to make an informed decision.

Cycle Time

The "slow and uniform" heating that minimizes deformation also means that vacuum furnace cycle times are generally longer than those for conventional atmospheric furnaces. This can impact throughput for high-volume production.

Equipment and Cost

Vacuum furnaces are sophisticated, high-capital-cost pieces of equipment. The cost per part for vacuum hardening may be higher than for simpler, less critical components treated in a conventional furnace.

Process Suitability

While highly versatile, vacuum hardening is not always necessary. For simple parts with loose dimensional tolerances where a scaled or discolored surface is acceptable or easily removed, a less expensive atmospheric process may be sufficient.

Making the Right Choice for Your Application

Selecting the correct heat treatment process requires aligning the method's capabilities with your component's specific requirements.

- If your primary focus is dimensional stability: Vacuum hardening is the superior choice for parts with complex geometries, tight tolerances, or thin walls that are prone to warping.

- If your primary focus is surface quality: Vacuum hardening is ideal for components that require a pristine, scale-free finish for aesthetic reasons or as preparation for a subsequent process like PVD coating or nitriding.

- If your primary focus is cost-effectiveness for low-tolerance parts: A conventional atmospheric heat treatment may be a more economical choice, provided that post-process cleaning and some level of distortion are acceptable.

Ultimately, understanding the principles behind the process empowers you to specify a heat treatment that delivers the required performance without over-engineering the solution.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Minimized Deformation | Uniform heating and controlled cooling reduce thermal stress and warping. |

| Eliminated Oxidation | Inert vacuum environment prevents surface reactions, ensuring scale-free finishes. |

Enhance your laboratory's precision with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior heat treatment outcomes. Contact us today to discuss how our tailored solutions can optimize your processes and deliver exceptional results for your specific applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion