The primary advantages of vacuum furnaces are their ability to produce an exceptionally clean, bright surface finish and achieve superior metallurgical properties in the treated material. By removing atmospheric gases, these furnaces prevent oxidation and other surface reactions, while enabling precise, uniform control over the entire heating and cooling cycle, resulting in enhanced strength, hardness, and process repeatability.

A vacuum furnace is not merely a tool for preventing rust; it is a highly controlled environment that allows you to engineer a material’s microstructure with a level of precision and consistency that atmospheric furnaces cannot match.

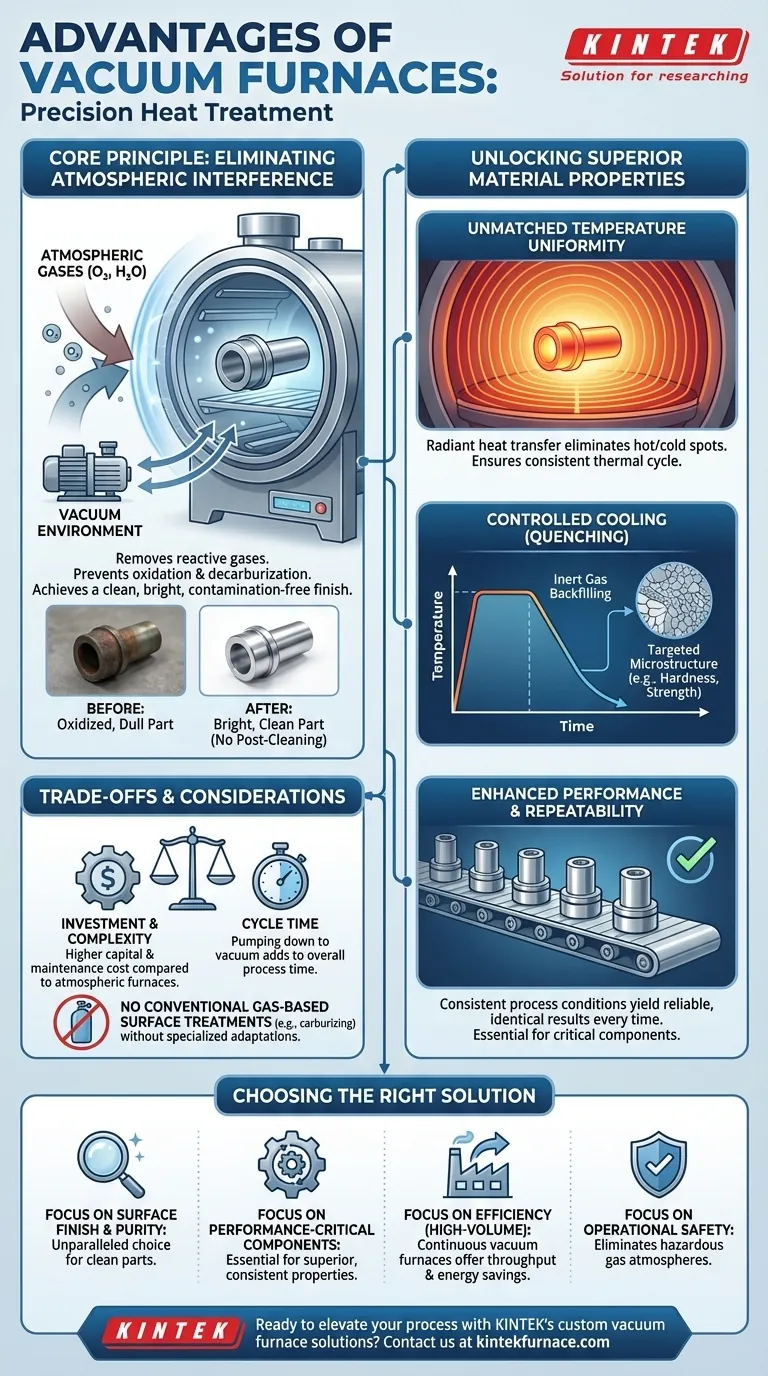

The Core Principle: Eliminating Atmospheric Interference

The defining feature of a vacuum furnace is the removal of the atmosphere. This single change fundamentally alters the heat treatment process and is the source of its most significant advantages.

Preventing Oxidation and Decarburization

At high temperatures, the oxygen and moisture in normal air aggressively react with a metal's surface. This causes oxidation (scaling) and decarburization (the loss of carbon from the surface of steel), both of which degrade the part's finish and mechanical properties.

A vacuum environment eliminates these reactive gases. The result is a clean, bright part that requires no subsequent cleaning and maintains its original surface chemistry.

Achieving a Contamination-Free Finish

Beyond just preventing oxidation, a vacuum actively purifies the workpiece. The process can perform degassing and degreasing, pulling volatile contaminants and oils out of the material and off its surface.

This ensures the final product is not just free of scale, but also metallurgically clean, which is critical for applications in aerospace, medical, and electronics.

Unlocking Superior Material Properties

The vacuum environment enables a level of process control that directly translates to better, more reliable material performance.

Unmatched Temperature Uniformity

Without an atmosphere to cause convection currents, heat is transferred primarily through radiation. This allows for extremely uniform heating across the entire workpiece, eliminating hot and cold spots.

This uniformity ensures that the entire part, regardless of its geometry, undergoes the exact same thermal cycle, leading to a consistent and predictable material structure.

Controlled Cooling for Targeted Microstructures

Vacuum furnaces offer precise control over the cooling (quenching) phase. By using inert gas backfilling at controlled pressures, operators can achieve a wide range of cooling rates.

This control is critical for targeting specific microstructures and achieving desired properties like hardness, toughness, and strength with incredible accuracy.

Enhanced Performance and Repeatability

The combination of a clean environment and precise thermal control means the process is highly repeatable. Each batch can be processed under the exact same conditions, yielding identical results every time.

This reliability is essential for performance-critical components where consistent mechanical and magnetic properties are non-negotiable.

Understanding the Trade-offs and Considerations

While powerful, vacuum furnaces are not a universal solution. An objective evaluation requires understanding their operational context.

Initial Investment and Complexity

Vacuum furnaces represent a significant capital investment compared to traditional atmospheric furnaces. They are complex systems requiring specialized maintenance for vacuum pumps, seals, and control systems.

Cycle Time

The process of pumping down the chamber to the required vacuum level adds time to the overall process cycle. For some high-volume, low-margin parts, this may be a limiting factor compared to continuous atmospheric furnaces.

No Gas-Based Surface Treatments

By their nature, vacuum furnaces are not suitable for conventional thermochemical processes that require a reactive gas atmosphere, such as carburizing or nitriding. While plasma-assisted versions of these processes exist for vacuum furnaces, they are a different technological category.

Making the Right Choice for Your Goal

The decision to use a vacuum furnace should be driven by the specific requirements of your component and production goals.

- If your primary focus is surface finish and purity: A vacuum furnace is the unparalleled choice for producing clean, bright, and contamination-free parts.

- If your primary focus is performance-critical components: The process control and repeatability of a vacuum furnace are essential for achieving consistent, superior metallurgical properties.

- If your primary focus is process efficiency in high-volume settings: A continuous vacuum furnace can offer significant energy savings and high throughput by minimizing downtime and temperature cycling.

- If your primary focus is operational safety: Vacuum furnaces eliminate the need to handle the costly and often flammable or explosive gas atmospheres required by some atmospheric processes.

Choosing a vacuum furnace is an investment in control, cleanliness, and consistency, enabling you to produce higher-quality components reliably.

Summary Table:

| Advantage | Description |

|---|---|

| Clean Surface Finish | Prevents oxidation and decarburization, resulting in bright, scale-free parts without post-cleaning. |

| Superior Metallurgical Properties | Enables precise control over microstructure for enhanced strength, hardness, and consistency. |

| Temperature Uniformity | Uses radiation for even heating, eliminating hot/cold spots and ensuring uniform treatment. |

| Controlled Cooling | Allows targeted cooling rates with inert gas for specific material properties like toughness. |

| High Repeatability | Consistent process conditions yield reliable results batch after batch. |

| Contamination-Free Environment | Removes volatile contaminants through degassing, ideal for aerospace and medical applications. |

Ready to elevate your heat treatment processes with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems, is backed by strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, medical, or electronics, we help you achieve superior metallurgical properties and contamination-free results. Contact us today to discuss how our vacuum furnaces can transform your operations!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today