For materials professionals, the choice of furnace technology is a defining decision. A vacuum furnace offers significant advantages for sintering primarily through its unparalleled control over the processing atmosphere, which prevents oxidation and contamination of sensitive materials. This pristine environment, combined with precise temperature management and controlled cooling rates, results in superior material properties, higher density, and exceptional metallurgical consistency that other methods cannot easily replicate.

The fundamental advantage of a vacuum furnace isn't just that it gets hot; it's that it creates a chemically pure, highly controlled environment. This allows you to dictate the exact thermal and atmospheric conditions needed to produce materials with superior, repeatable, and uncompromised quality.

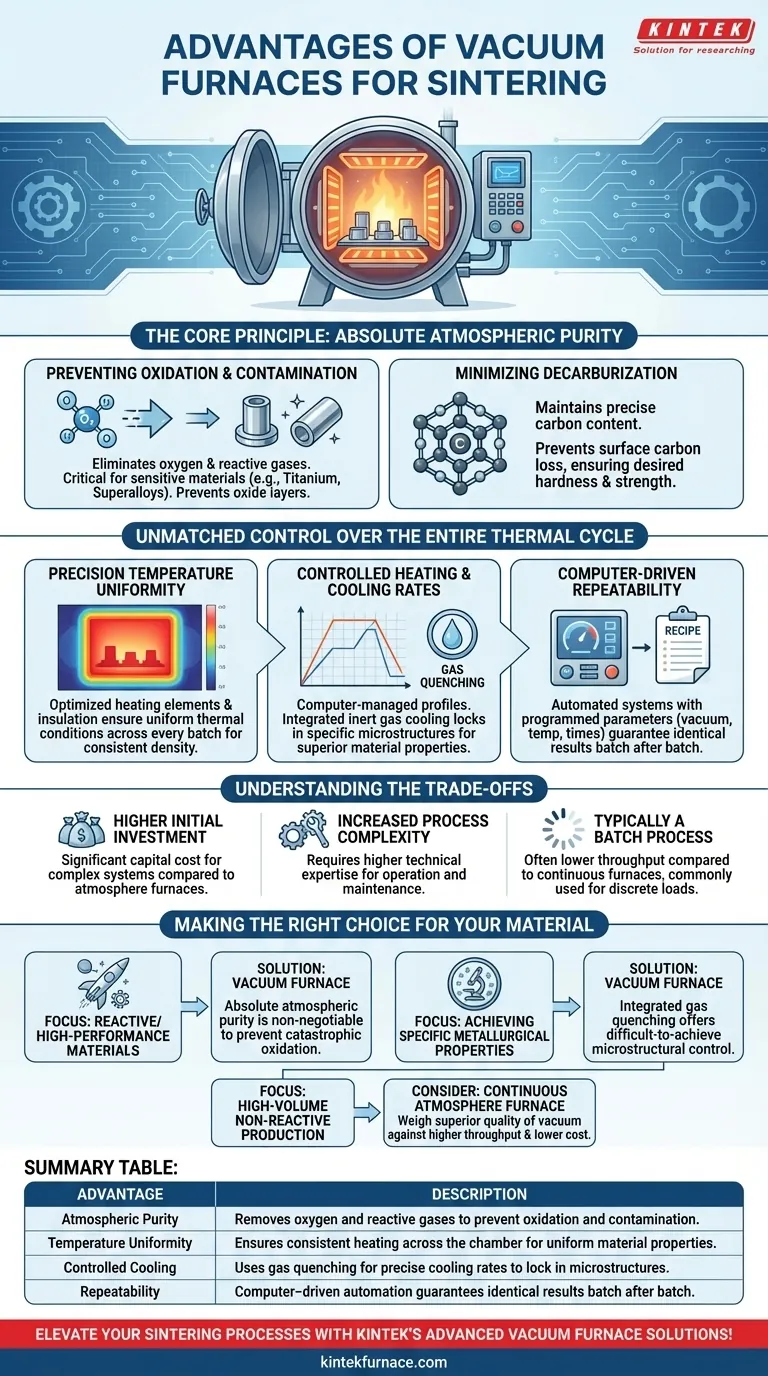

The Core Principle: Absolute Atmospheric Purity

The defining feature of a vacuum furnace is the removal of atmospheric gases. This seemingly simple act has profound implications for the quality of the final sintered part.

Preventing Oxidation and Contamination

By operating in a near-perfect vacuum, the furnace eliminates oxygen and other reactive gases. This is not just a benefit; it is an absolute requirement for processing materials that are highly sensitive to oxidation, such as titanium, superalloys, and certain advanced ceramics.

Without this protection, these materials would form oxide layers at high temperatures, compromising their structural integrity, surface finish, and overall performance.

Minimizing Decarburization

For many metal alloys, maintaining the precise carbon content is critical to achieving desired hardness and strength. The vacuum environment prevents decarburization—the loss of carbon from the material's surface—ensuring the chemical composition and material properties remain exactly as designed.

Unmatched Control Over the Entire Thermal Cycle

A vacuum furnace provides programmatic control over every stage of the sintering process, from the initial heating ramp to the final cooling phase. This level of management is key to achieving consistent, high-quality results.

Precision Temperature Uniformity

Modern vacuum furnaces are engineered with optimized heating elements and advanced insulation (like graphite or graphite paper) to ensure a highly uniform temperature throughout the heating chamber.

This uniformity ensures that every part in a batch, regardless of its position, experiences the same thermal conditions. The result is consistent density, grain structure, and performance across the entire production run.

Controlled Heating and Cooling Rates

The process is managed by a computer, allowing for precise, repeatable heating ramps and holding times. This is essential for complex sintering profiles.

Furthermore, vacuum furnaces enable rapid cooling through a process called gas quenching, where an inert gas is introduced to cool the parts at a controlled rate. This capability is critical for locking in specific metallurgical microstructures that define a material's final properties.

Computer-Driven Repeatability

With highly automated systems, every parameter—vacuum level, temperature, heating/cooling rates, and holding times—can be programmed into a "recipe." This removes operator variability and guarantees that every batch is processed identically, ensuring metallurgical repeatability for quality-critical applications.

Understanding the Trade-offs and Considerations

While powerful, vacuum furnaces are not the universal solution for every application. Acknowledging their trade-offs is key to making an informed decision.

Higher Initial Investment

Vacuum furnaces, with their complex vacuum pumps, control systems, and robust chamber construction, represent a significantly higher capital investment compared to conventional atmosphere furnaces.

Increased Process Complexity

Operating a vacuum furnace requires a higher level of technical expertise. Managing vacuum levels, leak detection, and maintenance schedules adds complexity compared to simpler furnace designs.

Typically a Batch Process

Most vacuum furnaces operate on a batch basis. While continuous vacuum furnaces exist, the technology is most commonly used for processing discrete loads, which can result in lower throughput compared to continuous belt furnaces used for high-volume production.

Making the Right Choice for Your Material

Your decision should be driven by the specific requirements of your material and the desired quality of the final component.

- If your primary focus is processing reactive or high-performance materials (like superalloys, titanium, or advanced ceramics): The absolute atmospheric purity of a vacuum furnace is non-negotiable to prevent catastrophic oxidation.

- If your primary focus is achieving specific metallurgical properties through controlled cooling: The integrated gas quenching capability offers a level of microstructural control that is difficult to achieve otherwise.

- If your primary focus is high-volume production of non-reactive materials: You must weigh the superior quality and repeatability of vacuum sintering against the potentially higher throughput and lower cost of a continuous atmosphere furnace.

Ultimately, choosing a vacuum furnace is an investment in absolute process control and the highest possible material quality.

Summary Table:

| Advantage | Description |

|---|---|

| Atmospheric Purity | Removes oxygen and reactive gases to prevent oxidation and contamination. |

| Temperature Uniformity | Ensures consistent heating across the chamber for uniform material properties. |

| Controlled Cooling | Uses gas quenching for precise cooling rates to lock in microstructures. |

| Repeatability | Computer-driven automation guarantees identical results batch after batch. |

Elevate your sintering processes with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer high-temperature furnaces like Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering superior material quality and repeatability. Contact us today to discuss how we can optimize your lab's efficiency and results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing