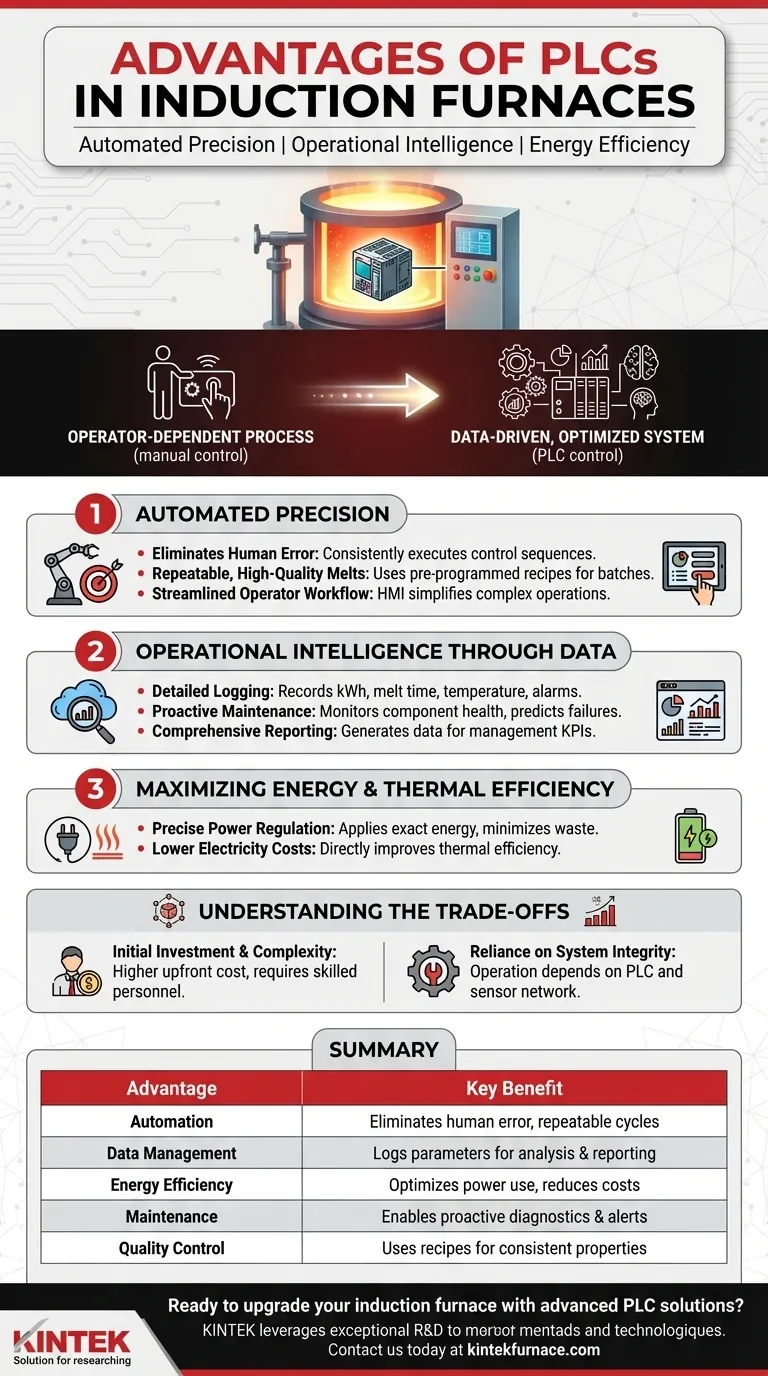

In short, integrating a Programmable Logic Controller (PLC) into an induction furnace transforms the operation by enabling precise process automation, consistent performance, and detailed data management. It replaces manual guesswork and disparate controls with a centralized, intelligent system that ensures every melt cycle is repeatable, efficient, and fully documented.

The core advantage of a PLC is not just automation; it is the transition from an operator-dependent process to a data-driven, highly optimized, and predictable manufacturing system. This shift unlocks significant gains in quality, efficiency, and operational intelligence.

From Manual Intervention to Automated Precision

The most immediate impact of a PLC is the move away from high-variance manual control. It systemizes the entire melting process, embedding expert knowledge directly into the machine's logic.

Eliminating Human Error

By automating control sequences, temperature holds, and power adjustments, a PLC removes the risk of operator mistakes. This ensures that every cycle runs according to a predefined, optimal standard.

This automation guarantees consistent, error-free performance, reducing scrap rates and wasted energy caused by incorrect manual inputs.

Repeatable, High-Quality Melts with Recipes

PLCs excel at managing "recipes"—pre-programmed sets of parameters for different alloys or charge sizes. An operator can select a recipe, and the PLC will automatically execute the entire melt cycle precisely.

This capability makes it easy to switch between production jobs while guaranteeing that the material properties of the final product are consistent batch after batch.

Streamlined Operator Workflow

Modern PLCs are paired with a Human-Machine Interface (HMI), a user-friendly touchscreen that visualizes the entire process.

This interface simplifies complex operations, provides clear alerts, and guides the operator, reducing the cognitive load and training time required to run the furnace effectively.

Unlocking Operational Intelligence Through Data

A PLC-controlled furnace is no longer a "black box." It becomes a source of valuable data that can be used for continuous improvement, maintenance, and management reporting.

Detailed Logging for Process Analysis

The PLC meticulously records every critical parameter of the melt cycle. This includes power consumption (kWh), melt time, temperature curves, and alarm histories.

This data is invaluable for process engineers looking to analyze performance, identify bottlenecks, and optimize energy usage or cycle times.

Proactive Maintenance and Diagnostics

The PLC constantly monitors the health of furnace components, from the power supply (like IGBTs) to cooling systems.

It can be programmed to flag anomalies or predict potential failures before they cause a shutdown, enabling a proactive rather than reactive maintenance strategy.

Comprehensive Reporting for Management

Data stored by the PLC can be easily extracted to generate detailed reports for analysis and compliance. This helps management track key performance indicators (KPIs) like energy cost per ton, overall equipment effectiveness (OEE), and production output.

Maximizing Energy and Thermal Efficiency

While technologies like medium-frequency power supplies and IGBTs are key to high thermal efficiency, a PLC acts as the brain required to extract their full potential.

Precise Power Regulation

A PLC can execute sophisticated power control strategies, applying exactly the right amount of energy at each stage of the melt. This prevents overheating and minimizes the energy wasted holding metal at temperature.

This precise control ensures that more of the input energy is directly used to melt the metal, directly improving the furnace's thermal efficiency and lowering electricity costs.

Understanding the Trade-offs

While highly beneficial, a PLC system is not a simple drop-in replacement. It represents a fundamental change in operational philosophy.

Initial Investment and Complexity

Upgrading to a PLC-based system involves a higher upfront cost for hardware, software, and integration. It also requires personnel with the skills to program and maintain the system, which may necessitate additional training.

Reliance on System Integrity

In a fully automated system, the operation is dependent on the PLC and its network of sensors. A failure in a critical sensor or the controller itself can halt production until it is repaired, whereas simpler manual systems might have rudimentary workarounds.

Making the Right Choice for Your Operation

The decision to adopt a PLC hinges on your specific operational goals.

- If your primary focus is consistent product quality: The ability to program, store, and execute precise melt recipes is the key advantage, eliminating batch-to-batch variation.

- If your primary focus is reducing operational costs: The PLC's precise power regulation and process automation will lower energy consumption and reduce expensive scrap caused by human error.

- If your primary focus is process optimization and data analysis: The comprehensive data logging provides the critical information needed to make informed decisions for continuous improvement and predictive maintenance.

Ultimately, a PLC transforms your furnace from a simple heating tool into an intelligent, data-driven production asset.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Automation | Eliminates human error, ensures repeatable cycles |

| Data Management | Logs parameters for analysis and reporting |

| Energy Efficiency | Optimizes power use, reduces costs |

| Maintenance | Enables proactive diagnostics and alerts |

| Quality Control | Uses recipes for consistent material properties |

Ready to upgrade your induction furnace with advanced PLC solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor solutions to meet your unique experimental needs, enhancing efficiency, quality, and operational intelligence. Contact us today to discuss how we can transform your lab's performance!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What components make up a Vacuum Induction Melting Furnace? Discover the Key Systems for Pure Metal Melting

- How does vacuum induction melting work? Achieve Ultra-Pure, High-Performance Alloys

- What industries benefit from Vacuum Induction Melting Furnaces? Unlock High-Purity Metals for Aerospace, Medical, and More

- What are the key components of a Vacuum Induction Melting (VIM) furnace? Master High-Purity Metal Processing

- What are the main applications of vacuum induction melting (VIM) furnaces? Achieve Unmatched Metal Purity for Critical Industries