Beyond simply reaching high temperatures, the primary advantages of Molybdenum Disilicide (MoSi₂) heating elements in sintering furnaces are their exceptional lifespan, operational stability, and heating efficiency. This performance is rooted in a unique self-healing property that protects the element from degradation in high-heat, oxygen-rich environments, ensuring consistent and repeatable sintering results.

While known for their 1800°C+ temperature capability, the true value of MoSi₂ elements lies in the self-healing silica layer that forms during operation. This layer provides unmatched durability and electrical stability, which are the cornerstones of a reliable high-temperature sintering process.

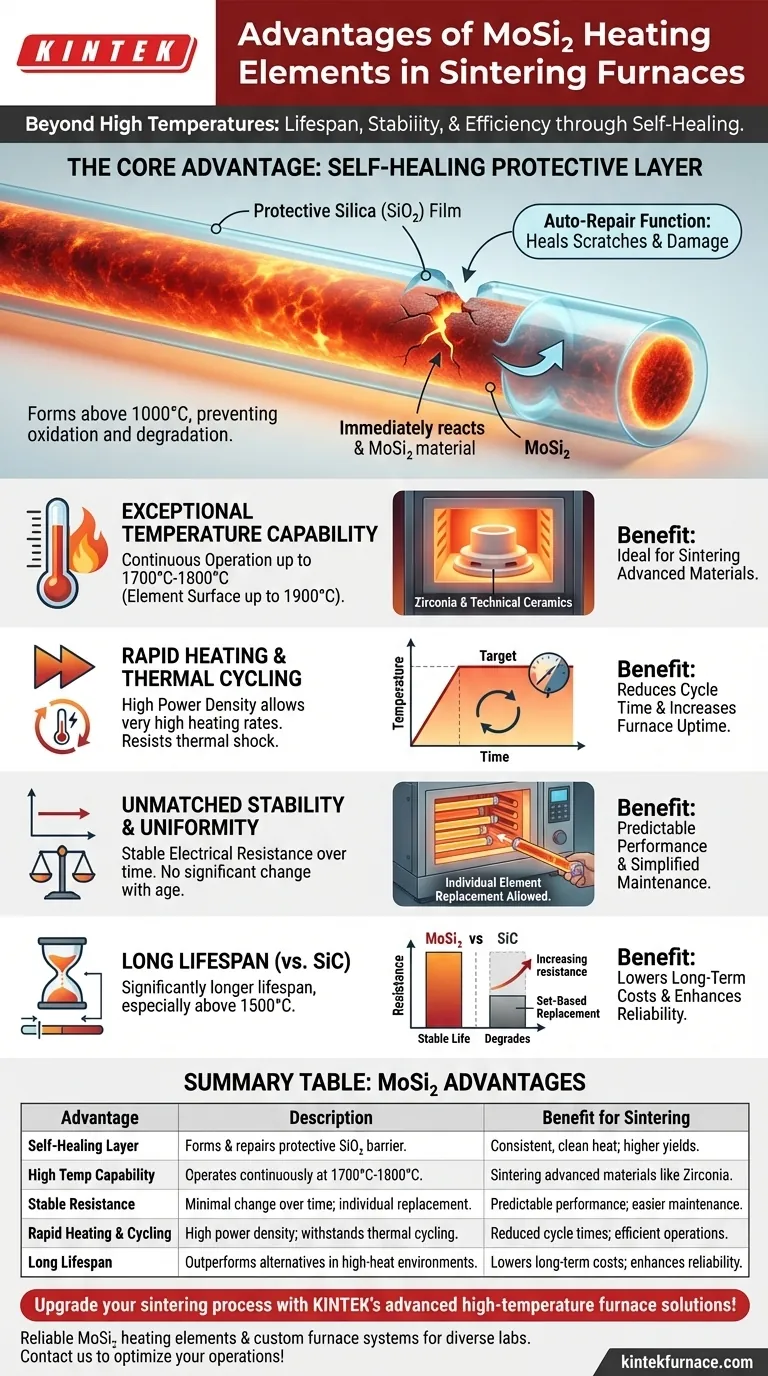

The Core Advantage: A Self-Healing Protective Layer

The defining characteristic of MoSi₂ elements is not just their composition, but how that composition behaves at extreme temperatures. This is the key to their longevity and reliability.

The Protective Silica (SiO₂) Film

At temperatures above 1000°C, the molybdenum disilicide material reacts with oxygen in the furnace atmosphere. This reaction forms a thin, non-porous layer of silica glass (SiO₂) on the element's surface.

This protective silica layer acts as a barrier, preventing further oxidation and chemical attack on the core heating element. If the layer is ever scratched or damaged, the underlying MoSi₂ is exposed and immediately "heals" itself by forming new silica glass, granting it an auto-repair function.

Why This Matters for Sintering

In sintering, process consistency is paramount. A degrading heating element can shed particles, contaminating the product and causing furnace hotspots or cold spots.

The stable, self-healing nature of MoSi₂ ensures highly uniform and clean heat. This directly translates to higher process yields, more consistent material density, and less furnace downtime for maintenance.

Translating Physics into Performance

The underlying chemistry of MoSi₂ gives rise to several distinct operational advantages that are critical for modern sintering applications.

Exceptional Temperature Capability

MoSi₂ elements are designed for the most demanding thermal processes. They can operate continuously at furnace temperatures up to 1700°C-1800°C, with element surface temperatures reaching as high as 1900°C in some variants.

This makes them essential for sintering advanced materials like zirconia and other technical ceramics that require extremely high processing temperatures.

Rapid Heating and Thermal Cycling

These elements have a high power density, allowing for very high heating rates. Furnaces equipped with MoSi₂ can reach their target temperature quickly, reducing overall cycle time.

Their structural integrity also makes them well-suited for applications involving rapid thermal cycling, where other elements might fail due to thermal shock.

Unmatched Stability and Uniformity

Unlike some alternative heating elements, the electrical resistance of MoSi₂ does not change significantly with age. This stability simplifies power control system design and ensures that heating performance remains predictable throughout the element's long life.

Because individual elements maintain their resistance, they can be replaced one at a time without affecting the performance of the remaining elements in the set.

Understanding the Trade-offs: MoSi₂ vs. SiC

To fully appreciate the advantages of MoSi₂, it's useful to compare it to the other common high-temperature element, Silicon Carbide (SiC).

Temperature Range and Lifespan

MoSi₂ is the clear choice for processes running above 1500°C, where its protective layer gives it a significantly longer lifespan than SiC. SiC elements have a maximum operating temperature of around 1530°C-1540°C in the furnace.

Resistance and Replacement Strategy

SiC's resistance increases as it ages, meaning performance degrades over time. When one SiC element fails, the entire set must often be replaced to maintain a balanced electrical load.

MoSi₂'s stable resistance allows for individual element replacement, significantly reducing maintenance costs and downtime.

Operational Sensitivity

The primary trade-off is MoSi₂'s sensitivity to certain conditions. The protective silica layer can be damaged by specific chemical contaminants. Therefore, maintaining a clean furnace environment is critical to realizing the full lifespan of MoSi₂ elements.

Making the Right Choice for Your Sintering Process

Your choice of heating element should be dictated by your specific material, process temperature, and operational priorities.

- If your primary focus is processing high-temperature ceramics (like Zirconia) above 1500°C: MoSi₂ is the superior choice for its unmatched temperature capability and long-term stability in that range.

- If your primary focus is maximizing furnace uptime and simplifying maintenance: MoSi₂'s stable resistance and ability to be replaced individually offers a significant advantage over elements that require set-based replacement.

- If your process operates below 1500°C and initial cost is the main driver: Silicon Carbide (SiC) may be a viable alternative, but you must factor in its shorter lifespan and more complex replacement requirements.

Ultimately, choosing MoSi₂ is an investment in process stability, repeatability, and long-term operational efficiency.

Summary Table:

| Advantage | Description | Benefit for Sintering |

|---|---|---|

| Self-Healing Silica Layer | Forms a protective barrier that repairs itself, preventing oxidation and degradation. | Ensures consistent, clean heat for higher yields and reduced contamination. |

| High Temperature Capability | Operates continuously at 1700°C-1800°C, with element surface up to 1900°C. | Ideal for sintering high-temperature materials like zirconia and technical ceramics. |

| Stable Electrical Resistance | Minimal change in resistance over time, simplifying power control. | Predictable performance and easier maintenance with individual element replacement. |

| Rapid Heating and Cycling | High power density allows fast heating rates and withstands thermal cycling. | Reduces cycle times and increases furnace uptime for efficient operations. |

| Long Lifespan | Outperforms alternatives like SiC in high-temperature environments due to durability. | Lowers long-term costs and maintenance frequency, enhancing process reliability. |

Upgrade your sintering process with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable MoSi2 heating elements and custom furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise alignment with your unique experimental needs, delivering enhanced efficiency, stability, and repeatability for high-temperature applications. Contact us today to discuss how we can optimize your sintering operations and achieve superior results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

People Also Ask

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing