In short, the primary advantage of an atmosphere furnace is its ability to precisely control the chemical environment during heat treatment. This control prevents unwanted reactions like oxidation, improves material quality and integrity, and enhances the efficiency of the entire manufacturing process, from energy use to final finishing.

An atmosphere furnace is not just a tool for applying heat; it is a highly controlled chemical reactor. Its core value lies in creating a specific, protective, or reactive gaseous environment that ensures the material being processed achieves its exact desired properties, free from contamination.

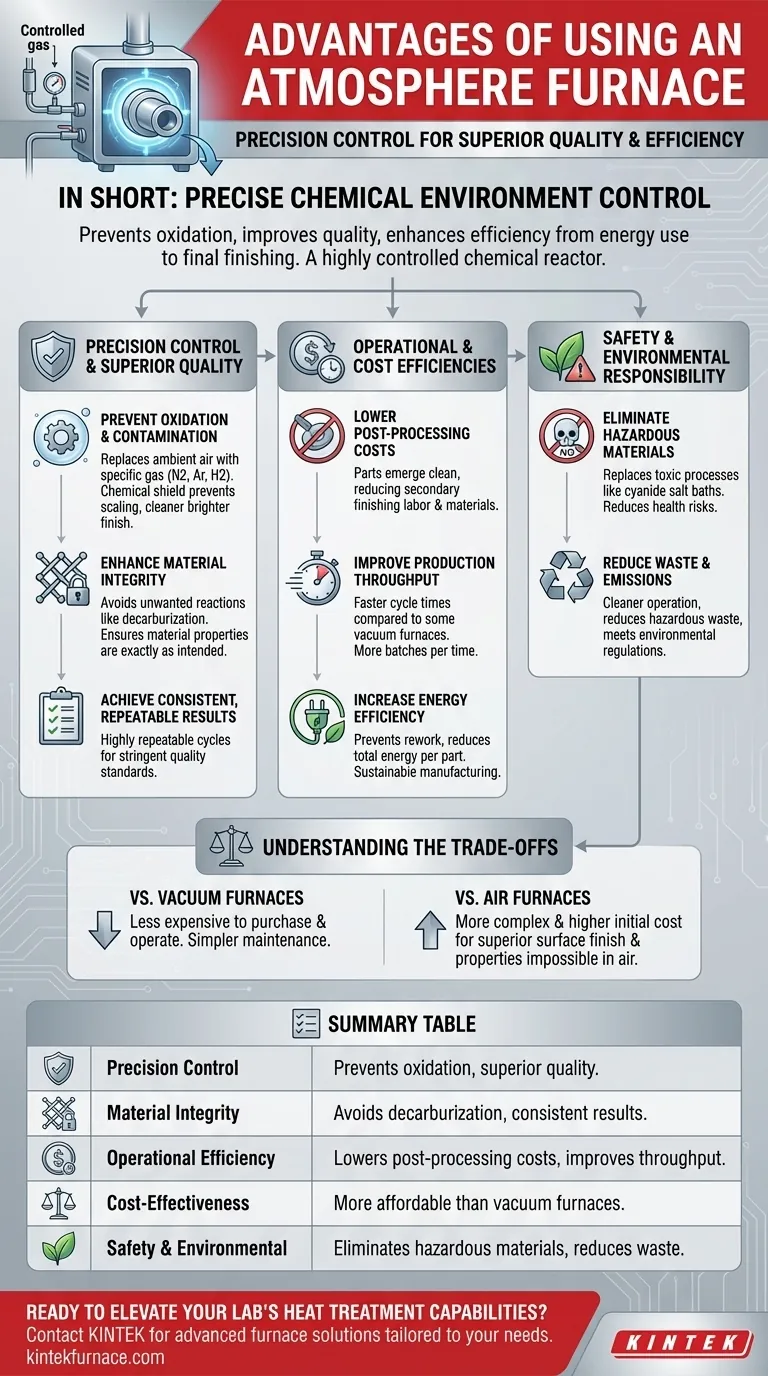

Precision Control for Superior Product Quality

The defining feature of an atmosphere furnace is its ability to manage the gas surrounding the workpiece. This directly translates to higher quality and more reliable outcomes.

Preventing Oxidation and Contamination

By replacing ambient air with a specific gas mixture (like nitrogen, argon, or hydrogen), you create a chemical shield. This prevents oxidation and scaling on the surface of metals, which would otherwise require costly and time-consuming secondary cleaning processes like sandblasting or acid pickling.

This controlled environment ensures the final product has a cleaner, brighter finish and is free from impurities that can compromise its performance.

Enhancing Material Integrity

Many heat treatment processes are designed to alter a material's properties in a very specific way. Unwanted chemical reactions can undermine this goal.

An atmosphere furnace avoids these issues, such as the decarburization (loss of carbon) of steel, which weakens the surface. By controlling the atmosphere, you ensure the material's integrity and mechanical properties are exactly as intended.

Achieving Consistent, Repeatable Results

The precision control over both temperature and atmosphere allows for highly repeatable process cycles. This consistency is critical in industries where slight variations can lead to component failure, ensuring every part meets the same stringent quality standards.

Significant Operational and Cost Efficiencies

While representing an investment, these furnaces deliver substantial returns through improved efficiency and lower long-term operating costs.

Lowering Post-Processing Costs

A major advantage is the reduction or elimination of post-treatment needs. Because parts emerge from the furnace clean and free of scale, the labor, materials, and time associated with secondary finishing are drastically cut.

Improving Production Throughput

Faster cycle times contribute directly to higher throughput. For example, when compared to high-vacuum furnaces, certain atmosphere furnaces can offer faster pump-down times and cooling cycles, allowing more batches to be processed in the same amount of time.

Increasing Energy Efficiency

Modern atmosphere furnaces are designed for high energy efficiency. By preventing the need for rework and extensive secondary processing, they also reduce the total energy consumed per part produced, making the entire manufacturing line more sustainable.

Understanding the Trade-offs

No single technology is perfect for every application. The choice to use an atmosphere furnace involves clear trade-offs against simpler air furnaces and more complex vacuum systems.

Cost-Effectiveness Compared to Vacuum Furnaces

For many applications, an atmosphere furnace provides the ideal balance of control and cost. It is generally less expensive to purchase and operate than a high-vacuum furnace.

Maintenance is also typically simpler and less costly due to the less stringent sealing and vacuum pump requirements.

Increased Complexity vs. Air Furnaces

Compared to a simple open-air furnace, an atmosphere furnace is more complex. It requires a reliable supply of process gases, sophisticated control systems, and operators with the knowledge to manage the atmospheric conditions correctly.

This added complexity and initial cost are the price of achieving superior surface finish and material properties that are impossible in an air environment.

Enhanced Safety and Environmental Responsibility

Atmosphere furnaces represent a significant step forward from older, hazardous heat treatment methods.

Eliminating Hazardous Materials

These furnaces can replace legacy processes that relied on toxic materials. For example, they eliminate the need for cyanide-based salt baths for carburizing or carbonitriding, which create significant health risks and land contamination problems.

Reducing Waste and Emissions

By operating cleanly, atmosphere furnaces reduce hazardous waste streams and the difficulties associated with disposing of contaminated salts or pack carburizing materials. This modern approach helps manufacturers meet stricter environmental regulations and reduces their carbon footprint.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your process requirements, quality standards, and budget.

- If your primary focus is cost-sensitive production that requires oxidation protection: An atmosphere furnace provides an excellent balance of quality control and operational efficiency without the high cost of a vacuum system.

- If your primary focus is achieving the absolute highest purity and degassing materials: A high-vacuum furnace may be necessary, as it provides an even cleaner environment than a controlled gas atmosphere.

- If your primary focus is simple heat treatment where surface oxidation is acceptable or desired: A basic air furnace remains the most economical and straightforward choice.

Ultimately, investing in an atmosphere furnace empowers you to control not just temperature, but the very chemistry of your manufacturing process.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Precision Control | Prevents oxidation and contamination for superior product quality |

| Material Integrity | Avoids decarburization and ensures consistent, repeatable results |

| Operational Efficiency | Lowers post-processing costs and improves production throughput |

| Cost-Effectiveness | More affordable than vacuum furnaces with simpler maintenance |

| Safety & Environmental | Eliminates hazardous materials and reduces waste and emissions |

Ready to elevate your lab's heat treatment capabilities? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line, including Atmosphere Furnaces, Muffle Furnaces, Tube Furnaces, Rotary Furnaces, Vacuum Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to precisely meet your unique experimental needs. Contact us today to discuss how our expertise can enhance your material quality and operational efficiency!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance

- What is the significance of nitrogen in atmosphere furnaces? Unlock Enhanced Heat Treatment and Surface Hardening

- Why is moisture control critical in inert atmosphere heat treating? Prevent Oxidation and Ensure Material Integrity