In a direct comparison, Microwave Plasma-Enhanced Chemical Vapor Deposition (MPCVD) offers significant advantages over both Low-Pressure CVD (LPCVD) and standard Plasma-Enhanced CVD (PECVD). MPCVD generally produces films of higher quality, purity, and uniformity, often at faster deposition rates and lower temperatures, which is critical for protecting sensitive underlying device structures from thermal damage.

The core difference lies in how energy is delivered to the precursor gases. While LPCVD relies on pure thermal energy and PECVD uses radio frequency (RF) or direct current (DC) plasma, MPCVD utilizes microwaves to create a more dense, uniform, and controllable plasma, enabling higher-performance films without the high temperatures of LPCVD or the potential quality compromises of standard PECVD.

The Fundamental Difference: How Energy Drives the Reaction

To understand the advantages of MPCVD, you must first understand the role of energy in the CVD process. The goal is to break down precursor gases into reactive species that then deposit onto a substrate as a thin film.

The Thermal Method: LPCVD

Low-Pressure Chemical Vapor Deposition (LPCVD) uses high temperatures, typically between 425°C and 900°C, to provide the thermal energy needed for these chemical reactions. It operates in a vacuum to ensure high film purity.

This purely thermal approach is like slow-cooking in a conventional oven. It can produce very high-quality, uniform films, but it is slow and the high heat limits its use to substrates that can withstand it.

The Standard Plasma Method: PECVD

Plasma-Enhanced Chemical Vapor Deposition (PECVD) introduced a major innovation: using an electric field (RF or DC) to create plasma. This plasma energizes the precursor gases, allowing the reaction to occur at much lower temperatures (200-400°C).

This is a significant improvement, enabling deposition on temperature-sensitive materials like plastics and polymers. It also dramatically increases deposition rates for certain materials.

MPCVD's Core Advantages Explained

MPCVD is a more advanced evolution of the plasma technique. By using microwaves instead of RF/DC fields, it creates a fundamentally different plasma environment, leading to several key benefits.

Superior Film Quality and Uniformity

MPCVD generates a much higher density of charged particles and reactive species within the plasma. This process is also more stable and spatially uniform.

The result is a deposited film with better homogeneity, stronger adherence to the substrate, and fewer defects like pinholes compared to what is often produced with standard PECVD.

Greater Process Control and Purity

Unlike other methods that might use filaments (like HFCVD), MPCVD is an electrodeless technique. This completely eliminates a major source of contamination, leading to higher-purity films.

The precise control of microwave energy also allows for finer-tuning of film properties, giving operators more control over the final material characteristics.

Low-Temperature Processing Without Compromise

Like PECVD, MPCVD operates at low temperatures, reducing the thermal stress on the substrate. This is crucial when fabricating complex, multi-layered devices where previous layers can be damaged by heat.

However, MPCVD achieves this low-temperature operation while often surpassing the film quality of high-temperature LPCVD, offering the best of both worlds for demanding applications.

Understanding the Trade-offs

No single technology is perfect for every use case. The choice between these methods involves a clear set of trade-offs between temperature, quality, and throughput.

The Limitation of LPCVD: The Temperature Barrier

The primary drawback of LPCVD is its reliance on high heat. This immediately disqualifies it for use with polymers, many compound semiconductors, or partially fabricated devices with low thermal budgets.

The Compromise of PECVD: Quality vs. Throughput

While PECVD is a versatile workhorse known for high throughput at low temperatures, its films can have drawbacks. They often contain higher levels of hydrogen and can suffer from more defects and pinholes, especially in thinner layers.

For many applications, this is an acceptable trade-off. For high-performance electronics or optics, these imperfections can be a critical failure point.

The Consideration for MPCVD: Complexity and Cost

As a more advanced technology, MPCVD systems are typically more complex and may represent a higher initial capital investment compared to standard PECVD or LPCVD setups. The decision to use MPCVD is therefore often driven by a strict requirement for the highest possible film quality.

Making the Right Choice for Your Application

Your final decision must be aligned with the specific performance requirements of your film and the limitations of your substrate.

- If your primary focus is ultimate film purity and stoichiometry on a robust substrate that can tolerate high heat: LPCVD remains a viable and well-understood option.

- If your primary focus is high-throughput deposition on temperature-sensitive substrates and minor film imperfections are acceptable: PECVD is a powerful and cost-effective workhorse.

- If your primary focus is achieving the highest possible film quality, purity, and uniformity for demanding applications, especially at low temperatures: MPCVD is the technically superior choice.

Ultimately, selecting the right deposition technology requires a clear understanding of what your application demands most: temperature tolerance, deposition speed, or film perfection.

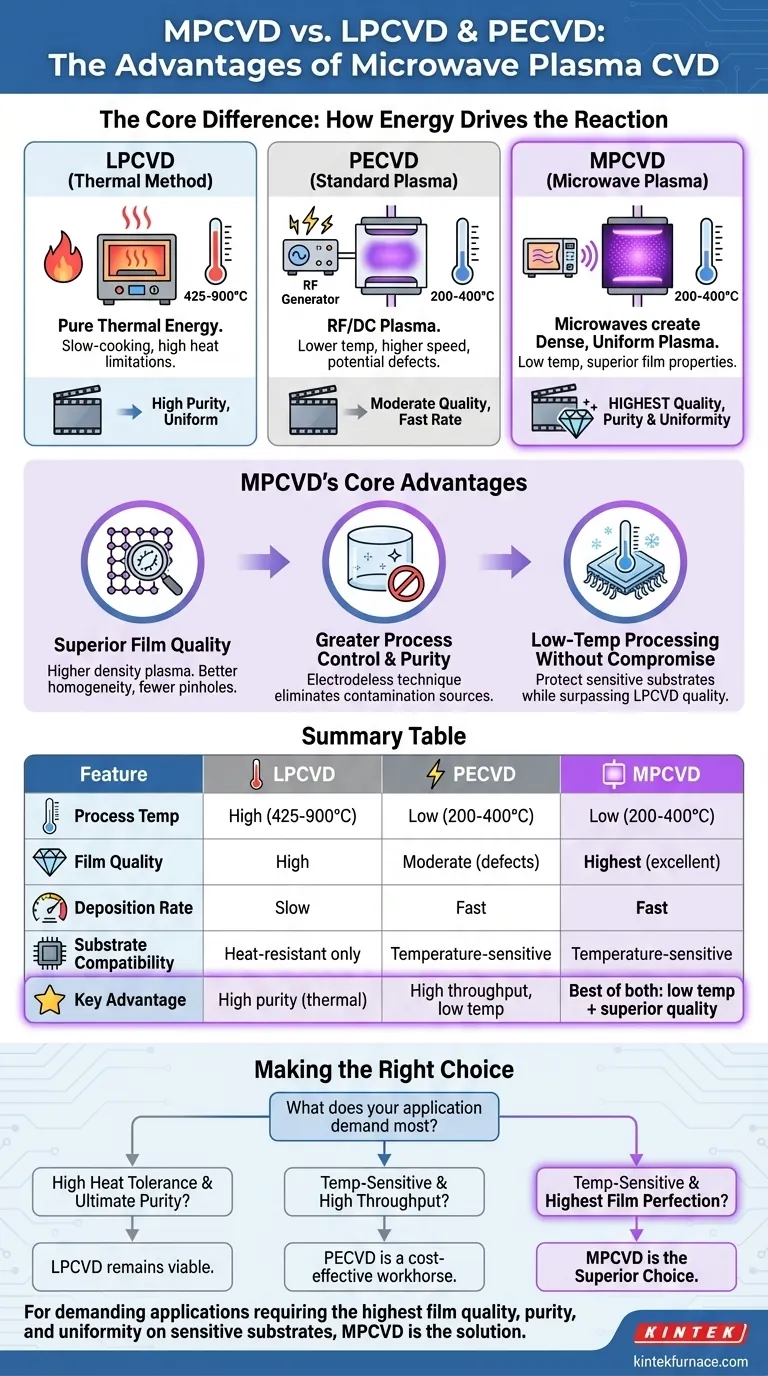

Summary Table:

| Feature | LPCVD | PECVD | MPCVD |

|---|---|---|---|

| Process Temperature | High (425-900°C) | Low (200-400°C) | Low (200-400°C) |

| Film Quality | High | Moderate (can have defects) | Highest (excellent uniformity & purity) |

| Deposition Rate | Slow | Fast | Fast |

| Substrate Compatibility | Heat-resistant only | Temperature-sensitive | Temperature-sensitive |

| Key Advantage | High purity (thermal process) | High throughput, low temp | Best of both: low temp + superior quality |

Need High-Performance Thin Films for Your Demanding Application?

Choosing the right CVD technology is critical to the success of your research or production. If your project requires the highest film quality, purity, and uniformity—especially on temperature-sensitive substrates—MPCVD is the superior solution.

KINTEK is your partner in advanced thermal processing. Leveraging our exceptional R&D and in-house manufacturing capabilities, we provide diverse laboratories with advanced high-temperature furnace solutions, including specialized systems for CVD applications. Our product line, featuring Muffle, Tube, and Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let us help you achieve perfection in your thin films. Contact our experts today to discuss how a customized KINTEK solution can elevate your process.

Visual Guide

Related Products

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What are the two main methods of synthetic diamond production? Discover HPHT vs. CVD for Lab-Grown Gems

- How is MPCVD used in the production of polycrystalline diamond optical components? Discover High-Purity Diamond Growth for Optics

- Who should perform maintenance on MPCVD equipment? Trust Certified Experts for Safety and Precision

- What is the basic principle of operation for the microwave plasma chemical vapor deposition system? Unlock High-Purity Material Growth

- Why is MPCVD considered a cornerstone of modern materials science and engineering? Unlock High-Purity Materials for Innovation