Among modern dental ceramics, lithium disilicate has secured its place as a cornerstone material for restorative dentistry. Its primary advantages lie in an exceptional and rare combination of lifelike aesthetics, derived from its glass-ceramic nature, and robust flexural strength that ensures clinical longevity for single-tooth restorations.

The core challenge in restorative dentistry is finding a single material that is both indistinguishable from a natural tooth and durable enough to withstand chewing forces. Lithium disilicate uniquely solves this by offering superior optical properties without significantly compromising on strength, making it the preferred choice for the aesthetic zone.

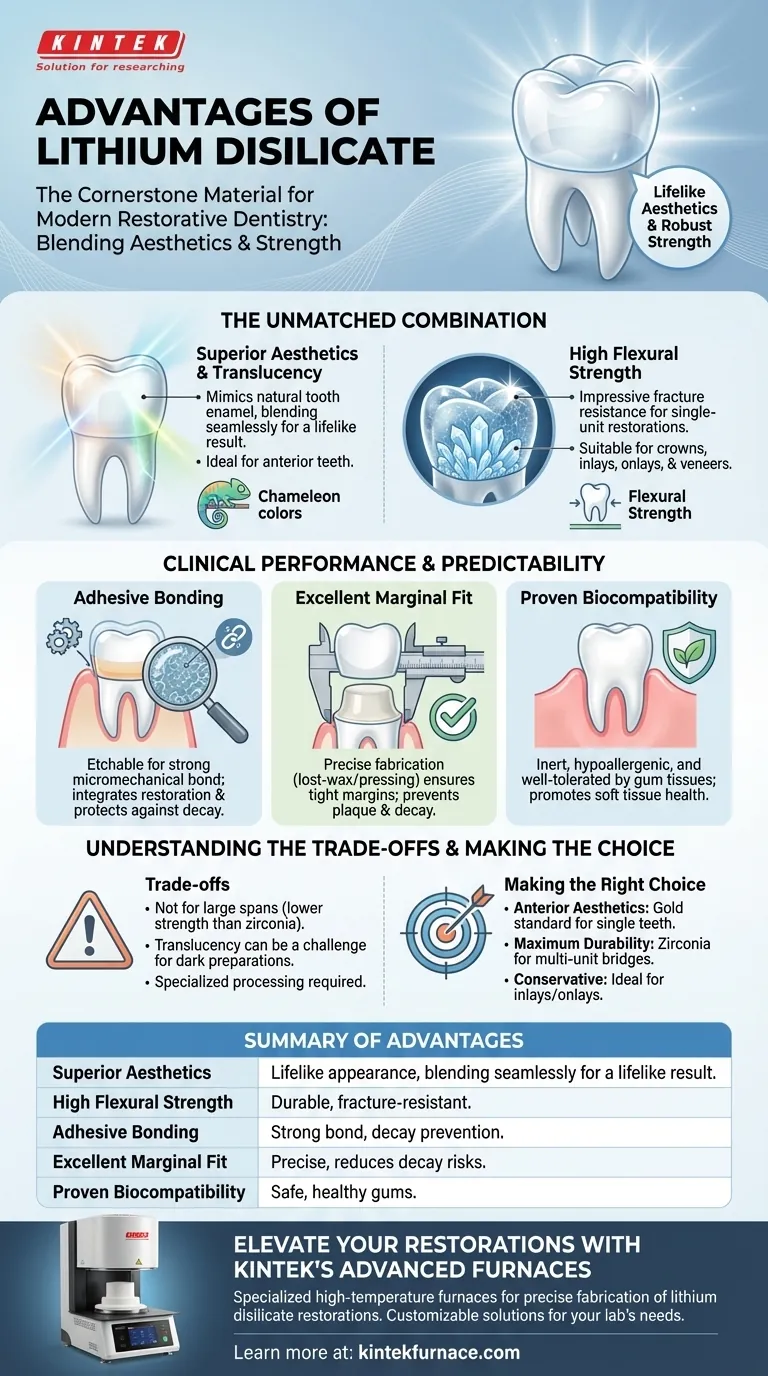

The Unmatched Combination of Aesthetics and Strength

The reputation of lithium disilicate is built on its ability to deliver two critical, often competing, restorative goals simultaneously.

Superior Aesthetics and Translucency

As a glass-ceramic, lithium disilicate allows light to pass through it in a manner that closely mimics natural tooth enamel. This creates a "chameleon effect," where the restoration picks up color from the underlying tooth structure, blending seamlessly for a truly lifelike result.

This inherent translucency is a significant advantage over more opaque materials like traditional zirconia or porcelain-fused-to-metal (PFM) crowns, especially for anterior teeth where aesthetics are paramount.

High Flexural Strength

Despite its glass-like appearance, the material is impressively strong and resistant to fracture. The crystalline structure of lithium disilicate provides a flexural strength that is more than sufficient for single-unit restorations anywhere in the mouth.

This durability makes it an excellent choice for full crowns, inlays, onlays, and veneers that must endure the daily rigors of mastication.

Clinical Performance and Predictability

Beyond its core properties, lithium disilicate offers tangible clinical benefits that contribute to long-term success.

Potential for Adhesive Bonding

Lithium disilicate can be etched with hydrofluoric acid, creating a microscopic pattern that allows for a powerful micromechanical bond with resin cements.

This adhesive capability integrates the restoration with the tooth, strengthening the entire system and creating a durable, sealed margin that protects against leakage and secondary decay.

Excellent Marginal Fit

The material is often fabricated using a heat-pressing, lost-wax technique. This highly controlled process allows dental laboratories to create restorations with incredibly precise and accurate margins.

A tight marginal fit is one of the most critical factors for the long-term health of a restoration, preventing plaque accumulation and recurrent decay at the junction of the crown and tooth.

Proven Biocompatibility

Lithium disilicate is a highly biocompatible and inert material. It does not cause allergic reactions and is well-tolerated by the surrounding gum tissues, promoting excellent soft tissue health around the restoration.

Understanding the Trade-offs

No material is perfect for every situation. Understanding the limitations of lithium disilicate is key to its successful application.

Strength Limitations for Large Spans

While very strong for single units, lithium disilicate does not possess the absolute fracture toughness of solid zirconia. For this reason, it is generally not the recommended material for multi-unit bridges in the posterior, where functional stresses are highest.

Translucency Can Be a Disadvantage

The same translucency that provides its superior aesthetics can become a challenge when trying to block out a dark or discolored underlying tooth preparation. In these specific cases, a more opaque material or special-use opaque lithium disilicate ingots may be necessary.

Processing Requirements

Fabricating pressed lithium disilicate restorations requires specialized furnaces and technical expertise in the dental laboratory. This precision-driven process, while yielding excellent results, is distinct from other workflows like milling zirconia.

Making the Right Choice for Your Goal

Selecting the correct material is about matching its properties to the clinical demand of the specific case.

- If your primary focus is anterior aesthetics for a single tooth: Lithium disilicate is the gold standard for crowns and veneers due to its unmatched translucency and natural appearance.

- If your primary focus is maximum durability for a multi-unit posterior bridge: A stronger material like full-strength monolithic zirconia is the more predictable choice.

- If your primary focus is a conservative, bonded restoration: The strength and bondability of lithium disilicate make it an ideal material for inlays and onlays that preserve tooth structure.

Understanding these core principles allows you to leverage lithium disilicate's unique properties for predictable and beautiful clinical outcomes.

Summary Table:

| Advantage | Description |

|---|---|

| Superior Aesthetics | Mimics natural tooth translucency for seamless blending and lifelike appearance. |

| High Flexural Strength | Provides durability for single-tooth restorations, resisting fractures from chewing forces. |

| Adhesive Bonding | Allows strong micromechanical bonds with resin cements for enhanced integration and decay prevention. |

| Excellent Marginal Fit | Ensures precise fit through controlled fabrication, reducing risks of plaque and recurrent decay. |

| Proven Biocompatibility | Inert and hypoallergenic, promoting healthy gum tissues and patient safety. |

Elevate your dental restorations with KINTEK's advanced solutions! We specialize in providing high-temperature furnaces essential for fabricating precise lithium disilicate restorations. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by deep customization capabilities to meet your unique laboratory needs. Whether you're a dental lab focusing on aesthetic crowns or durable inlays, our expertise ensures optimal performance and efficiency. Contact us today to learn how we can support your success with tailored furnace solutions!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

- Stainless Steel KF ISO Vacuum Flange Blind Plate for High Vacuum Systems

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision