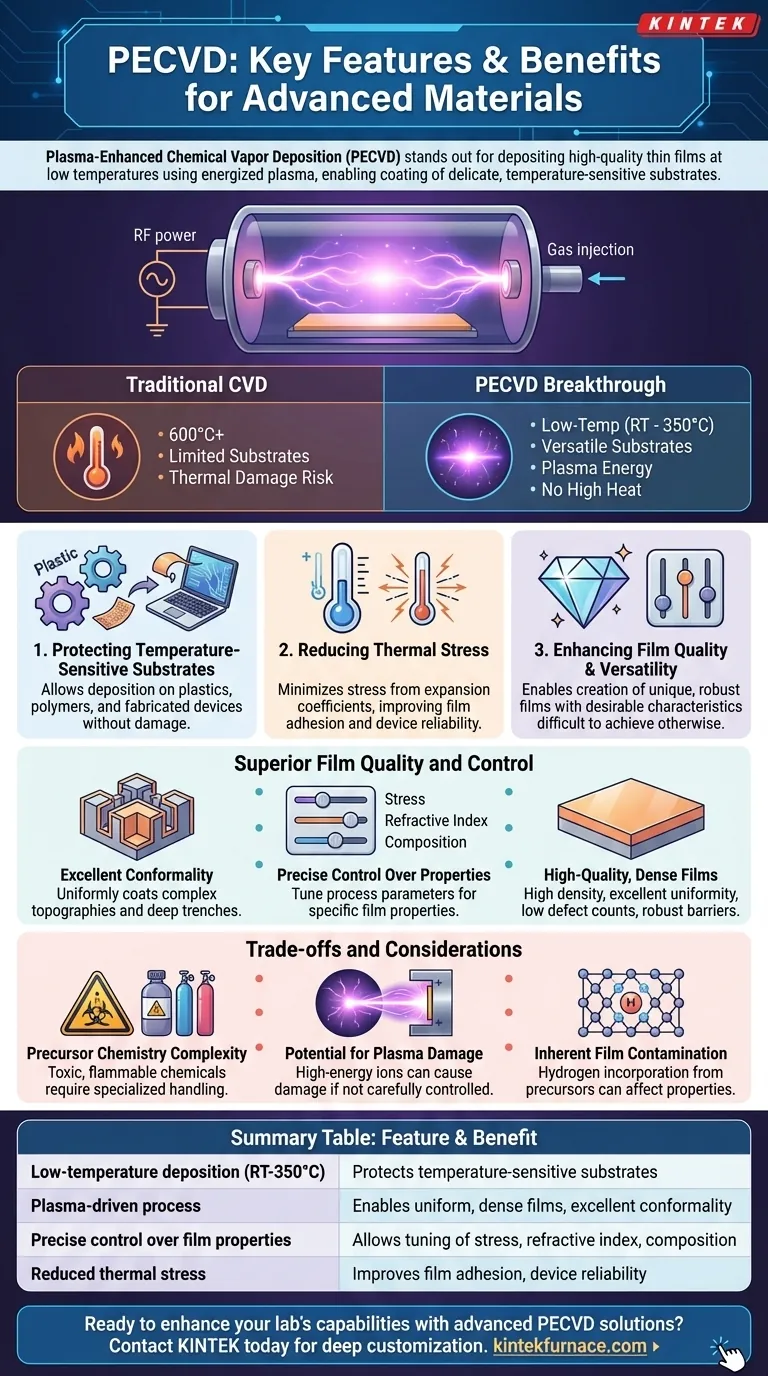

In the world of advanced material science, Plasma-Enhanced Chemical Vapor Deposition (PECVD) stands out for its unique ability to deposit high-quality thin films at significantly lower temperatures than traditional methods. This core capability, driven by the use of an energized plasma, allows for the coating of delicate, temperature-sensitive substrates without causing thermal damage, opening up a wide range of applications in electronics, optics, and medical devices.

The central advantage of PECVD is its substitution of high thermal energy with plasma energy. This fundamental shift allows for the deposition of durable, uniform, and complex films at low temperatures, overcoming the limitations of conventional high-heat processes.

The Core Principle: Plasma Instead of Heat

To understand the benefits of PECVD, you must first grasp how it fundamentally differs from conventional Chemical Vapor Deposition (CVD).

How Conventional CVD Works

Traditional CVD relies on extremely high temperatures, often over 600°C, to provide the thermal energy needed to break down precursor gases. These decomposed molecules then react and deposit as a solid thin film on the heated substrate.

This high-heat requirement severely limits the types of materials that can be used as substrates.

The PECVD Breakthrough: Energizing Gas with Plasma

PECVD bypasses the need for extreme heat. Instead, it introduces energy into the system using a radio frequency (RF) field to ignite the precursor gases into a plasma, an ionized gas state.

This plasma provides the necessary energy for the chemical reactions to occur at or near the substrate surface, allowing for deposition at much lower temperatures, typically ranging from room temperature to 350°C.

Key Benefits of Low-Temperature Deposition

The ability to operate at low temperatures is not just an incremental improvement; it is a transformative feature that unlocks several critical benefits.

Protecting Temperature-Sensitive Substrates

This is the most celebrated advantage of PECVD. It allows for the deposition of robust films onto materials like plastics, polymers, and fully fabricated semiconductor devices that would be damaged or destroyed by the high heat of conventional CVD.

Reducing Thermal Stress

When materials with different thermal expansion coefficients are heated and cooled together, it creates stress at their interface. This stress can lead to film cracking, delamination, and device failure.

By minimizing the process temperature, PECVD dramatically reduces this thermal stress, improving film adhesion and the overall reliability of the final component.

Enhancing Film Quality and Versatility

The plasma-driven process enables the creation of films with unique and desirable characteristics that are difficult to achieve with other methods.

Superior Film Quality and Control

Beyond temperature, the plasma environment gives engineers and scientists an unparalleled level of control over the final film's properties.

Excellent Conformality and Step Coverage

Because the deposition process is driven by reactive gas species, PECVD is not a "line-of-sight" technique. It can uniformly coat complex, three-dimensional topographies and deep trenches with excellent conformality, a key advantage over many Physical Vapor Deposition (PVD) methods.

Precise Control Over Film Properties

By tuning process parameters like RF power, frequency, gas mixture, and pressure, operators can precisely control the film's final properties. This includes its stress (often managed by mixing high and low RF frequencies), refractive index, hardness, and chemical composition (stoichiometry).

High-Quality, Dense Films

PECVD films are known for their high density, excellent uniformity over large areas, and low defect counts, such as fewer pinholes. This results in robust barrier layers with outstanding chemical resistance and durability.

Understanding the Trade-offs and Considerations

No technology is without its challenges. An objective assessment of PECVD requires acknowledging its complexities.

Precursor Chemistry Complexity

The choice of precursor gases is critical to the film's properties and the process's safety. These chemicals can be toxic, flammable, or corrosive, requiring specialized handling and safety infrastructure.

Potential for Plasma Damage

While the plasma enables low-temperature deposition, the high-energy ions within it can sometimes cause physical or electrical damage to highly sensitive substrates if the process is not carefully controlled.

Inherent Film Contamination

Many precursor gases used in PECVD (e.g., silane, SiH₄) contain hydrogen. It is common for hydrogen to be incorporated into the deposited film, which can affect its electrical or optical properties. This must be accounted for in device design.

Making the Right Choice for Your Goal

PECVD is a powerful tool, but its suitability depends entirely on your specific objective.

- If your primary focus is depositing on plastics or organic electronics: PECVD is the superior choice, as its low-temperature process prevents substrate damage.

- If your primary focus is coating complex 3D topographies: PECVD's excellent conformality offers a significant advantage over line-of-sight PVD techniques.

- If your primary focus is tuning specific optical or mechanical film properties: The fine control over process parameters in PECVD provides an invaluable engineering capability.

- If your primary focus is maximum simplicity and lowest cost for a simple metal film: A simpler PVD method like sputtering or thermal evaporation might be a more practical starting point.

Ultimately, understanding that PECVD's power lies in its plasma-driven, low-temperature process empowers you to leverage its unique capabilities for advanced material engineering.

Summary Table:

| Feature | Benefit |

|---|---|

| Low-temperature deposition (room temp to 350°C) | Protects temperature-sensitive substrates like plastics and polymers |

| Plasma-driven process | Enables uniform, dense films with excellent conformality |

| Precise control over film properties | Allows tuning of stress, refractive index, and composition |

| Reduced thermal stress | Improves film adhesion and device reliability |

Ready to enhance your lab's capabilities with advanced PECVD solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with cutting-edge high-temperature furnace solutions, including our specialized CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for thin film deposition. Contact us today to discuss how our PECVD systems can drive your innovations forward!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process

- What are the advantages of using CVD? Achieve High-Purity, Conformal Thin Films for Your Applications