At its core, a gas barrier film is an advanced material engineered to prevent gases like oxygen and water vapor from permeating through it. Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a critical manufacturing process used to create these barriers by depositing an exceptionally thin, dense, and uniform protective layer onto a substrate, such as a flexible plastic film.

The fundamental challenge with standard packaging is its molecular porosity. PECVD solves this by applying an ultra-thin, glass-like layer (such as silicon oxide) onto a flexible film, creating a hybrid material with vastly superior barrier properties essential for preserving sensitive products.

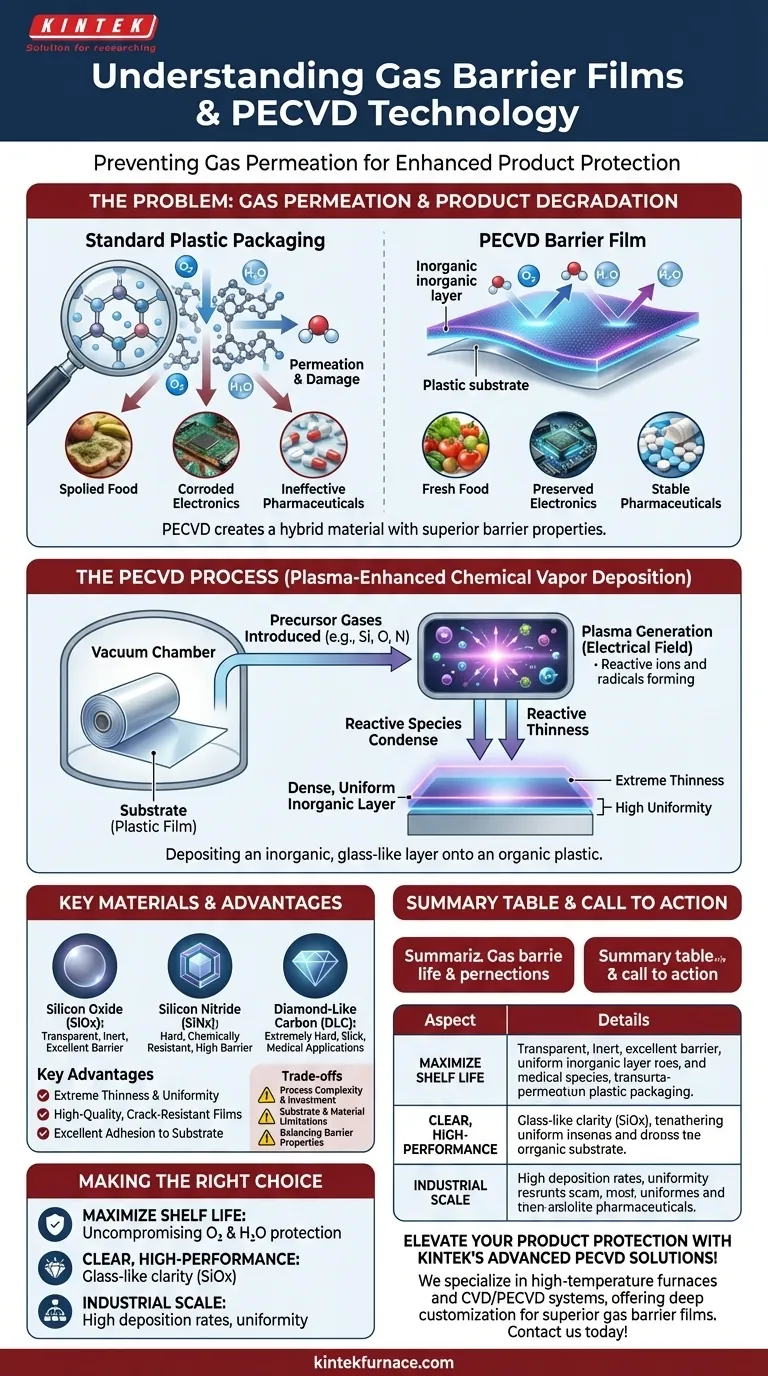

The Fundamental Problem: Gas Permeation

Why Standard Plastics Fall Short

Most common polymers used in packaging are permeable on a microscopic level. Their long-chain molecule structure contains gaps that allow small gas molecules, especially oxygen (O₂) and water vapor (H₂O), to slowly pass through.

For many applications, this is not a problem. However, for sensitive goods, this gradual exchange with the outside atmosphere is highly destructive.

The Impact on Product Integrity

Gas permeation is a primary driver of degradation. Oxygen exposure leads to oxidation, which causes food to spoil, changes the efficacy of pharmaceuticals, and can corrode delicate electronic components.

Similarly, moisture ingress can ruin dry foods, degrade powders, and cause short circuits in electronics. A high-performance barrier film directly addresses this root cause of failure.

How PECVD Creates a Superior Barrier

The PECVD Process in Brief

PECVD is a process that uses plasma—an energized state of gas—to deposit thin films. Inside a vacuum chamber, precursor gases are introduced and excited by an electrical field, forming a plasma.

This energy breaks the gas molecules apart into reactive ions and radicals. These reactive species then condense onto the surface of a substrate (like a roll of plastic film), reassembling as a solid, dense, and perfectly uniform layer.

Creating an Impermeable Inorganic Layer

The key to a PECVD barrier is that it deposits an inorganic material, like glass, onto an organic material, like plastic. This creates a hybrid structure with the best properties of both.

The deposited layer is incredibly dense and lacks the molecular gaps found in polymers, creating a formidable barrier to gas molecules.

Key Materials for Barrier Films

While PECVD can deposit many materials, a few are ideal for barrier applications due to their inertness and barrier properties.

- Silicon Oxide (SiOx): The most common choice for food and pharmaceutical packaging. It is chemically inert, transparent ("glass-on-film"), and provides an excellent barrier against both oxygen and moisture.

- Silicon Nitride (SiNx): Offers exceptional barrier performance and is also very hard and chemically resistant.

- Diamond-Like Carbon (DLC): An extremely hard and slick coating that provides an excellent gas barrier, often used in more demanding mechanical or medical applications.

Key Advantages of the PECVD Approach

Extreme Thinness and Uniformity

PECVD can create films that are mere nanometers thick. This means the barrier layer adds negligible weight or thickness to the final package and does not compromise the flexibility of the underlying plastic. The process ensures this ultra-thin layer is perfectly uniform, without the pinholes that would undermine its barrier function.

High-Quality, Crack-Resistant Films

The low-temperature nature of the PECVD process reduces stress in the deposited film. This results in a high-quality layer that is resistant to cracking, even when the flexible substrate is bent or folded.

Excellent Adhesion

The energized plasma in the PECVD process also cleans and activates the substrate surface just before deposition. This ensures the barrier film bonds tenaciously to the plastic, preventing delamination that would create a pathway for gases.

Understanding the Trade-offs

Process Complexity and Investment

PECVD equipment is sophisticated and operates under a vacuum, representing a significant capital investment compared to simpler coating methods like spraying or dipping. The process requires precise control over gas flow, pressure, and power.

Substrate and Material Limitations

While PECVD is a "low-temperature" process compared to other deposition techniques, it still introduces energy that can damage highly sensitive substrates. Furthermore, the choice of precursor gases is critical and requires specialized handling and safety protocols.

Balancing Barrier Properties

No single material is perfect. A specific film like SiOx might be optimized for oxygen resistance, while another might be better for moisture. Often, multi-layer coatings are required to achieve the desired balance of properties, adding to process complexity.

Making the Right Choice for Your Application

The decision to use PECVD barrier films is driven by the need for uncompromising protection.

- If your primary focus is maximizing shelf life for sensitive foods or pharmaceuticals: PECVD-coated films offer the highest level of oxygen and moisture protection available in a flexible format.

- If your primary focus is creating clear, high-performance packaging: SiOx films deposited via PECVD provide glass-like clarity and barrier performance on a fully flexible plastic film.

- If your primary focus is industrial-scale production: The high deposition rates and exceptional uniformity of PECVD make it a reliable and scalable solution for high-volume manufacturing.

Ultimately, PECVD empowers manufacturers to create packaging that moves beyond simple containment to provide active, long-term product preservation.

Summary Table:

| Aspect | Details |

|---|---|

| Gas Barrier Film Definition | Advanced material preventing gas permeation (e.g., oxygen, water vapor) |

| PECVD Role | Deposits thin, dense, uniform inorganic layers (e.g., SiOx, SiNx) on substrates |

| Key Advantages | Extreme thinness, uniformity, crack resistance, excellent adhesion |

| Common Applications | Food packaging, pharmaceuticals, electronics protection |

| Trade-offs | High process complexity, substrate limitations, material balancing |

Elevate your product protection with KINTEK's advanced PECVD solutions! We specialize in high-temperature furnaces, including CVD/PECVD systems, tailored for diverse laboratory needs. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique requirements—ensuring superior gas barrier films for sensitive applications. Contact us today to discuss how our technology can enhance your packaging and preservation outcomes!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties