Ceramic heating elements are the definitive choice for applications demanding high temperatures, long-term durability, and operational stability in challenging environments. They are widely used in everything from industrial furnaces and semiconductor manufacturing to common household appliances like water heaters and high-performance soldering irons where traditional metallic elements would quickly fail.

The core reason to select a ceramic heater is not just for heat, but for its ability to deliver that heat reliably under conditions that would degrade, corrode, or destroy a metal-based element. Its value lies in its exceptional chemical and thermal resilience.

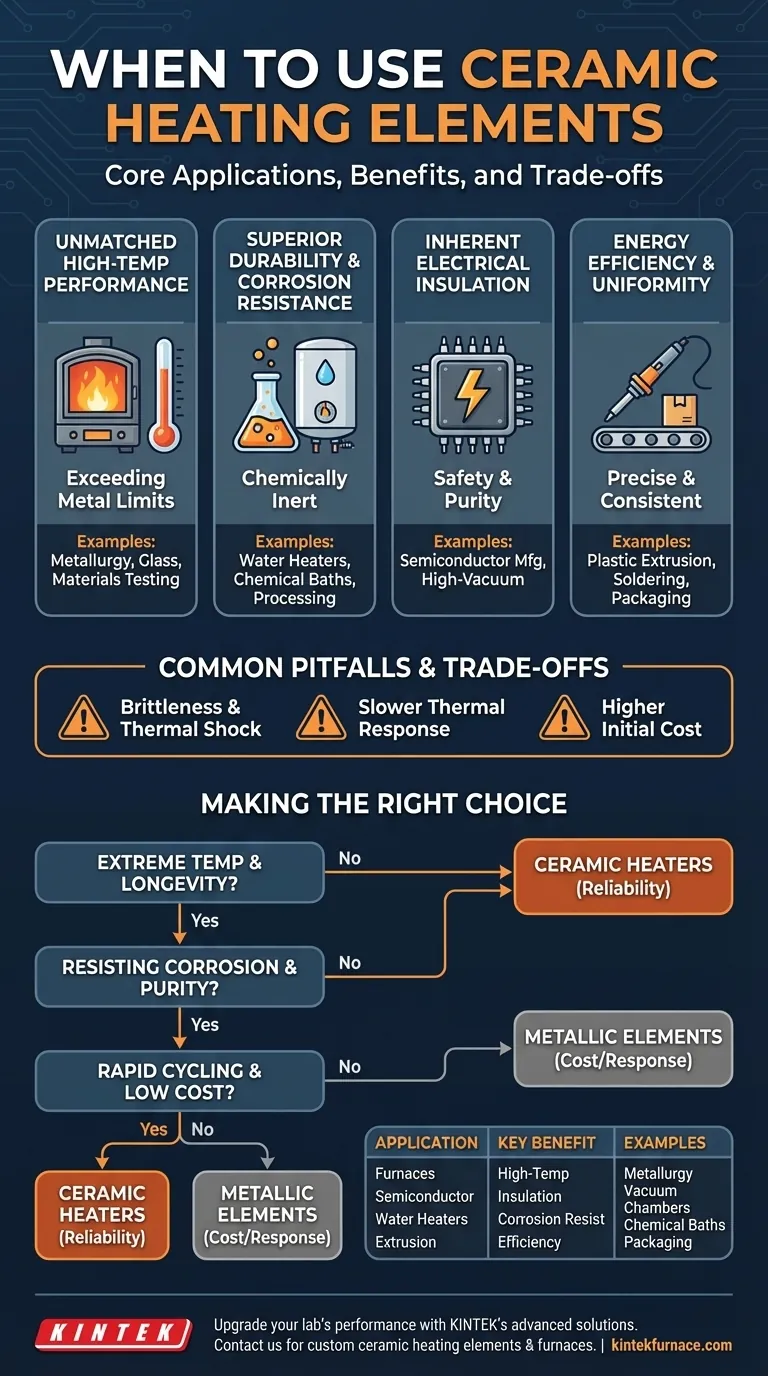

The Core Properties Driving Application Fit

To understand where ceramic heaters excel, you must first understand their fundamental advantages over metallic alternatives. The application is a direct consequence of these properties.

Unmatched High-Temperature Performance

Ceramic materials, such as silicon carbide (SiC) and molybdenum disilicide (MoSi2), can operate at extremely high temperatures without melting, warping, or oxidizing. This makes them indispensable for processes that run hotter than metals can handle.

This property is critical for high-temperature furnaces used in metallurgy, glass production, and materials testing, as well as large-scale tunnel kilns requiring continuous, intense heat.

Superior Durability and Corrosion Resistance

Ceramics are chemically inert. They do not rust or corrode when exposed to moisture or aggressive chemicals. This inherent resistance translates directly to a longer service life and lower maintenance costs.

This makes them the ideal choice for water heaters, industrial baths, and equipment used in chemical processing where corrosive agents are present.

Inherent Electrical Insulation

Unlike metal heaters, ceramic elements are excellent electrical insulators. This property is a significant safety feature, drastically reducing the risk of short circuits.

This insulation is vital in sensitive applications like semiconductor processing, high-vacuum chambers, and high-purity environments where electrical arcing could be catastrophic.

Energy Efficiency and Uniformity

Ceramic elements retain heat exceptionally well, allowing them to maintain a target temperature with less energy consumption once heated. They can also be engineered to provide highly uniform heat distribution.

This is why they are used in plastic extrusion, packaging machinery, and soldering equipment, where precise and consistent temperature control is critical for product quality.

Common Pitfalls and Trade-offs to Consider

While powerful, ceramic heaters are not a universal solution. An objective assessment requires understanding their limitations.

Brittleness and Thermal Shock

Ceramics are more brittle than metals. They can crack or fracture if subjected to significant physical impact or rapid, extreme temperature changes (thermal shock). Care must be taken during installation and in applications with high vibration.

Slower Thermal Response

Because they retain heat so well, ceramic heaters can sometimes have a slower response time for both heating up and cooling down compared to lower-mass metallic elements. This is a trade-off for their thermal stability.

Higher Initial Cost

The manufacturing process for high-performance ceramic elements can be more complex than for simple wire-wound heaters. This can result in a higher initial purchase price, though it is often offset by a longer service life and lower energy costs.

Making the Right Choice for Your Application

Your final decision should be based on the primary demand of your operating environment.

- If your primary focus is extreme temperature and longevity: Ceramic heaters are the superior choice, especially for continuous industrial processes in furnaces and kilns.

- If your primary focus is resisting corrosion or ensuring purity: The chemically inert nature of ceramic makes it essential for water heating, chemical baths, and semiconductor manufacturing.

- If your primary focus is rapid cycling and low initial cost: You may need to evaluate whether a metallic element is a better fit, accepting the trade-offs in durability and temperature limits.

Ultimately, choosing a ceramic heater is a decision to invest in reliability for environments where failure is not an option.

Summary Table:

| Application | Key Benefit | Examples |

|---|---|---|

| High-Temperature Furnaces | Unmatched high-temperature performance | Metallurgy, glass production, materials testing |

| Semiconductor Manufacturing | Inherent electrical insulation | High-vacuum chambers, sensitive processing |

| Water Heaters and Industrial Baths | Superior corrosion resistance | Chemical processing, household appliances |

| Plastic Extrusion and Soldering | Energy efficiency and uniform heat | Packaging machinery, soldering equipment |

Upgrade your lab's performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable ceramic heating elements and custom furnace designs, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique experimental needs, enhancing durability, efficiency, and safety. Contact us today to discuss how we can support your high-temperature and corrosive environment applications!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What is the difference between SiC and MoSi2? Choose the Right High-Temp Heating Element

- What is the operating temperature of SiC? Unlock Reliable Performance Up to 1600°C

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat