From an operational standpoint, electric rotary kilns offer significant advantages over traditional fuel-based models primarily through superior efficiency, process purity, and environmental performance. Their core benefits include near-perfect thermal efficiency, the complete elimination of emissions like smoke and ash, and highly precise, automated temperature control that is difficult to achieve with combustion.

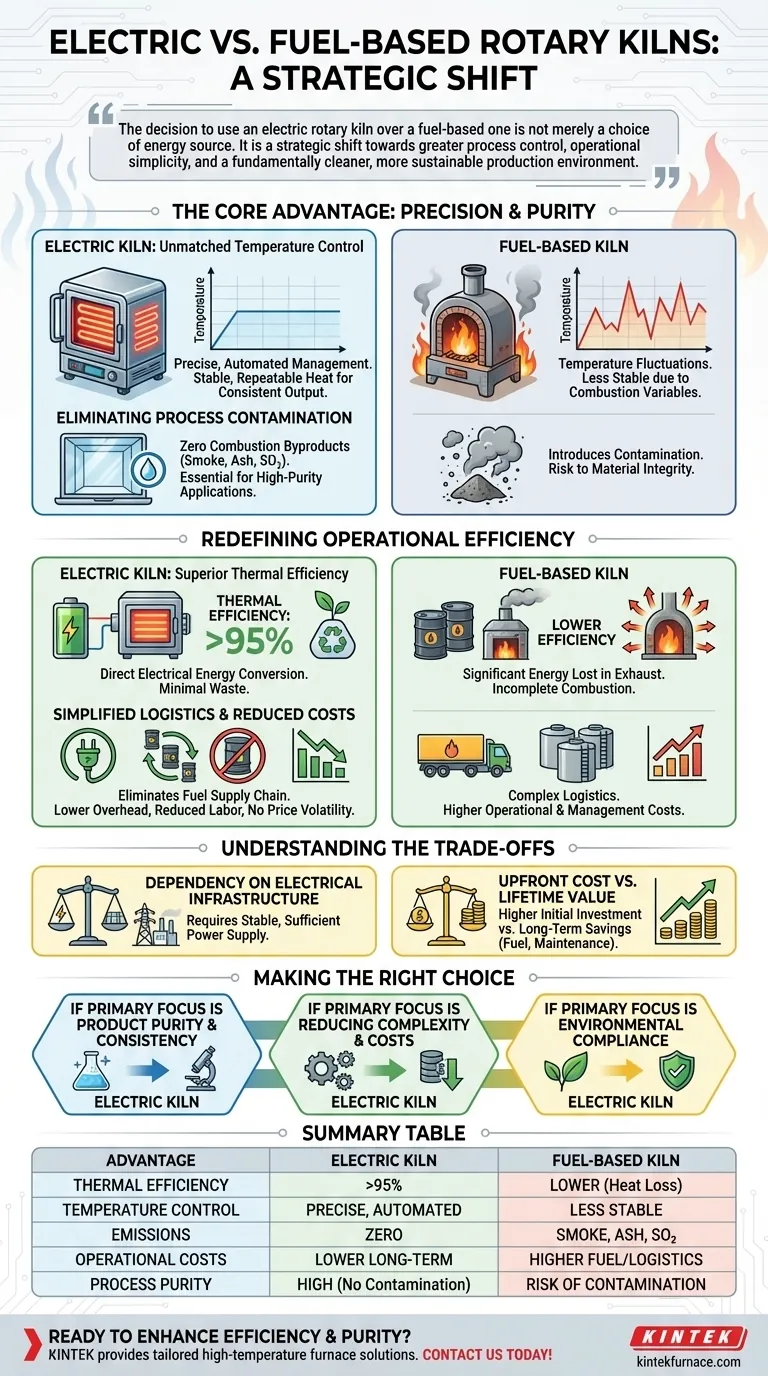

The decision to use an electric rotary kiln over a fuel-based one is not merely a choice of energy source. It is a strategic shift towards greater process control, operational simplicity, and a fundamentally cleaner, more sustainable production environment.

The Core Advantage: Precision and Purity

The primary distinction of an electric kiln lies in how it generates and applies heat, which directly impacts the quality of the final product.

Unmatched Temperature Control

Electric heating elements allow for precise, automated management of the temperature curve. This enables processors to meet the narrow thermal windows required for sensitive materials.

Unlike fuel-fired kilns, which can have temperature fluctuations due to combustion variables, electric systems provide stable, repeatable heat for consistent output.

Eliminating Process Contamination

Fuel-based kilns inherently introduce byproducts of combustion—such as smoke, ash, and sulfur dioxide (SO₂)—into the processing chamber.

Electric kilns are entirely free of this contamination. This makes them essential for high-purity applications, including the roasting of chemical molecular sieves, oxidation reactions, and calcining processes where material integrity is paramount.

Redefining Operational Efficiency

Beyond product quality, electric kilns change the economic and logistical calculations of high-temperature processing.

Superior Thermal Efficiency

An electric rotary kiln can achieve a thermal efficiency of over 95%. This is because electrical energy is converted directly into heat inside the kiln with minimal waste.

In contrast, a significant portion of the energy in fuel-fired kilns is lost as hot exhaust gases and incomplete combustion, lowering their overall efficiency.

Simplified Logistics and Reduced Costs

Operating an electric kiln eliminates the entire supply chain associated with fuel. There is no need for fuel purchasing, transportation, on-site storage, or management systems.

This simplification translates directly to lower operational overhead, reduced labor requirements, and immunity to the price volatility and logistical challenges of the fossil fuel market.

Understanding the Trade-offs

While the advantages are compelling, a clear-eyed assessment requires acknowledging the primary dependency of this technology.

Dependency on Electrical Infrastructure

The foremost consideration for an electric kiln is the availability of a stable and sufficient electrical power supply at the facility.

For some sites, this may require collaboration with the utility provider or investment in upgrading the local electrical infrastructure to support the kiln's power draw.

The Upfront Cost vs. Lifetime Value

While the references focus on lower operational costs, the initial capital investment for an electric kiln may differ from a traditional model.

A proper cost-benefit analysis must weigh the long-term savings from eliminated fuel logistics, higher efficiency, and reduced maintenance against the upfront purchase and installation price.

Making the Right Choice for Your Process

Your specific production goals should guide your decision between an electric and fuel-based system.

- If your primary focus is product purity and consistency: The precise, contaminant-free heating of an electric kiln is the superior choice for sensitive materials.

- If your primary focus is reducing operational complexity and costs: Electric kilns eliminate the logistics, price volatility, and management overhead of fuel.

- If your primary focus is environmental compliance and site safety: The emission-free operation and elimination of on-site fuel storage make electric kilns a definitive advantage.

Ultimately, adopting an electric rotary kiln represents a move toward a more predictable, controllable, and responsible industrial process.

Summary Table:

| Advantage | Electric Kiln | Fuel-Based Kiln |

|---|---|---|

| Thermal Efficiency | >95% | Lower due to heat loss |

| Temperature Control | Precise and automated | Less stable |

| Emissions | Zero | Smoke, ash, SO₂ |

| Operational Costs | Lower long-term | Higher fuel/logistics |

| Process Purity | High, no contamination | Risk of contamination |

Ready to enhance your lab's efficiency and product purity with advanced electric rotary kilns? KINTEK leverages exceptional R&D and in-house manufacturing to provide tailored solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental needs. Contact us today to discuss how our high-temperature furnace solutions can benefit your process!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

People Also Ask

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency