In short, silicon carbide (SiC) heating elements are used in industrial applications that demand reliable, high-temperature heating in harsh environments. They are the go-to solution for industries like metallurgy, ceramics and glass manufacturing, semiconductor production, and high-temperature chemical processing, where conventional metallic elements would quickly fail.

The decision to use silicon carbide heaters is driven by the need for process stability at extreme temperatures. When an application's temperature or chemical environment exceeds the limits of metal alloys, SiC becomes the default choice for performance and longevity.

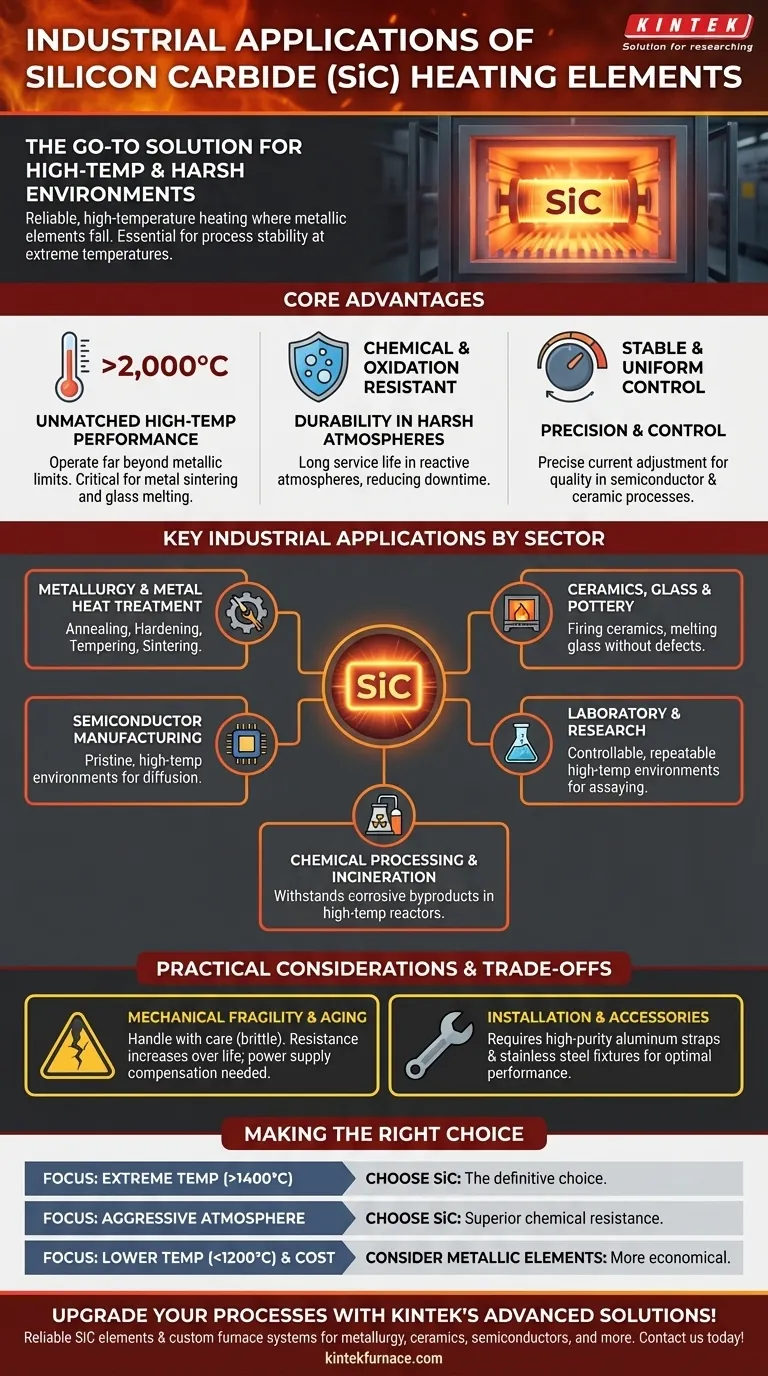

Why Silicon Carbide? The Core Advantages

Understanding why SiC elements are chosen over other technologies comes down to a few key properties. These advantages directly address the challenges of high-temperature industrial work.

Unmatched High-Temperature Performance

Silicon carbide elements are engineered to operate at extremely high temperatures, with some capable of reaching over 2,000°C (3,632°F). This is far beyond the operational ceiling of traditional metallic heating elements, making them essential for processes like metal sintering and glass melting.

Durability in Harsh Atmospheres

Industrial furnaces often contain chemically reactive atmospheres. SiC is highly resistant to oxidation and chemical attack, ensuring a long service life even in these demanding conditions. This reliability reduces costly downtime and maintenance.

Precision and Control

Heat is generated by passing an electric current through the SiC element. By precisely adjusting this current, operators can achieve very stable and uniform temperature control, which is critical for ensuring product quality in sensitive processes like semiconductor manufacturing and ceramic firing.

Key Industrial Applications by Sector

The unique properties of SiC heaters make them indispensable across a range of specialized industries.

Metallurgy and Metal Heat Treatment

In metallurgy, precise temperature cycles are everything. SiC elements provide the high heat needed for processes like annealing, hardening, tempering, and the sintering of powdered metals in furnaces where consistency is paramount.

Ceramics, Glass, and Pottery

Firing ceramics and melting glass requires sustained, uniform high temperatures. SiC elements are used extensively in industrial kilns and furnaces to ensure products are fired correctly without hot spots or temperature drops that could cause defects.

Semiconductor Manufacturing

The production of semiconductors requires pristine, high-temperature environments. SiC heaters are used in diffusion furnaces and other thermal processing equipment where temperature uniformity and a non-contaminating heat source are critical.

Laboratory and Research Furnaces

For research, development, and material testing (assaying), SiC elements provide the controllable and repeatable high-temperature environments necessary for accurate experimental results. Their versatility makes them a staple in lab settings.

Chemical Processing and Incineration

SiC's chemical resilience makes it ideal for use in high-temperature chemical reactors and industrial incinerators. These elements can withstand corrosive byproducts while providing the necessary heat for thermal decomposition or chemical reactions.

Understanding the Trade-offs and Practical Considerations

While powerful, SiC elements are not a universal solution. Acknowledging their specific requirements is key to successful implementation.

Mechanical Fragility

Unlike ductile metals, silicon carbide is a ceramic and is inherently brittle. The elements must be handled and installed with care to prevent mechanical shock or stress, which can lead to fracture.

Aging and Resistance Increase

Over their service life, SiC elements gradually "age," meaning their electrical resistance increases. The power supply system must be able to compensate for this change by delivering higher voltage over time to maintain the desired power output.

Installation and Accessories

Proper installation is non-negotiable. It requires specific accessories like high-purity aluminum connecting straps for optimal electrical conductivity and stainless steel fixtures to securely mount the elements without causing mechanical stress.

Making the Right Choice for Your Process

Selecting the correct heating element technology is a crucial engineering decision. Base your choice on the core demands of your application.

- If your primary focus is extreme temperature (>1400°C): Silicon carbide is the definitive choice, as most metallic elements cannot perform reliably in this range.

- If your primary focus is operating in a chemically aggressive atmosphere: The superior chemical resistance of SiC provides a longer service life and greater process stability.

- If your primary focus is cost-sensitivity at lower temperatures (<1200°C): Traditional metallic elements (like Kanthal A-1) may offer a more economical solution.

By understanding these fundamental trade-offs, you can confidently select the heating technology that delivers the performance and reliability your application demands.

Summary Table:

| Application | Key Benefits | Temperature Range |

|---|---|---|

| Metallurgy & Metal Heat Treatment | High-temperature stability, precise control | Up to 2,000°C |

| Ceramics, Glass & Pottery | Uniform heating, durability in kilns | High temperatures |

| Semiconductor Manufacturing | Non-contaminating, uniform temperature | Critical for clean processes |

| Laboratory & Research | Controllable, repeatable environments | Versatile high-temp settings |

| Chemical Processing & Incineration | Chemical resistance, reliable in harsh atmospheres | Withstands corrosive conditions |

Upgrade your industrial processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable silicon carbide heating elements and custom furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise solutions for your unique high-temperature and harsh environment needs, enhancing efficiency and longevity. Contact us today to discuss how we can support your applications in metallurgy, ceramics, semiconductors, and more!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the advantages of using high purity green silicon carbide powder in heating elements? Boost Efficiency and Lifespan

- What are the properties and capabilities of Silicon Carbide (SiC) as a heating element? Unlock Extreme Heat and Durability

- What is the maximum temperature silicon carbide heating elements can withstand? Key Factors for Longevity and Performance

- What makes silicon carbide heating elements resistant to chemical corrosion? Discover the Protective Oxide Layer

- Why are SiC heating elements considered environmentally friendly? Discover Their Eco-Efficiency & Lifespan Insights