At a glance, a rotary kiln and a rotary dryer are nearly identical, but their operational purpose is fundamentally different. A rotary dryer is designed for the low-temperature task of removing moisture, while a rotary kiln is engineered to use high temperatures to induce chemical reactions or phase changes within a material.

The choice between a kiln and a dryer is not about the equipment's shape but about the thermal process you need to achieve. Dryers are for simple moisture removal, whereas kilns are for high-temperature material transformation.

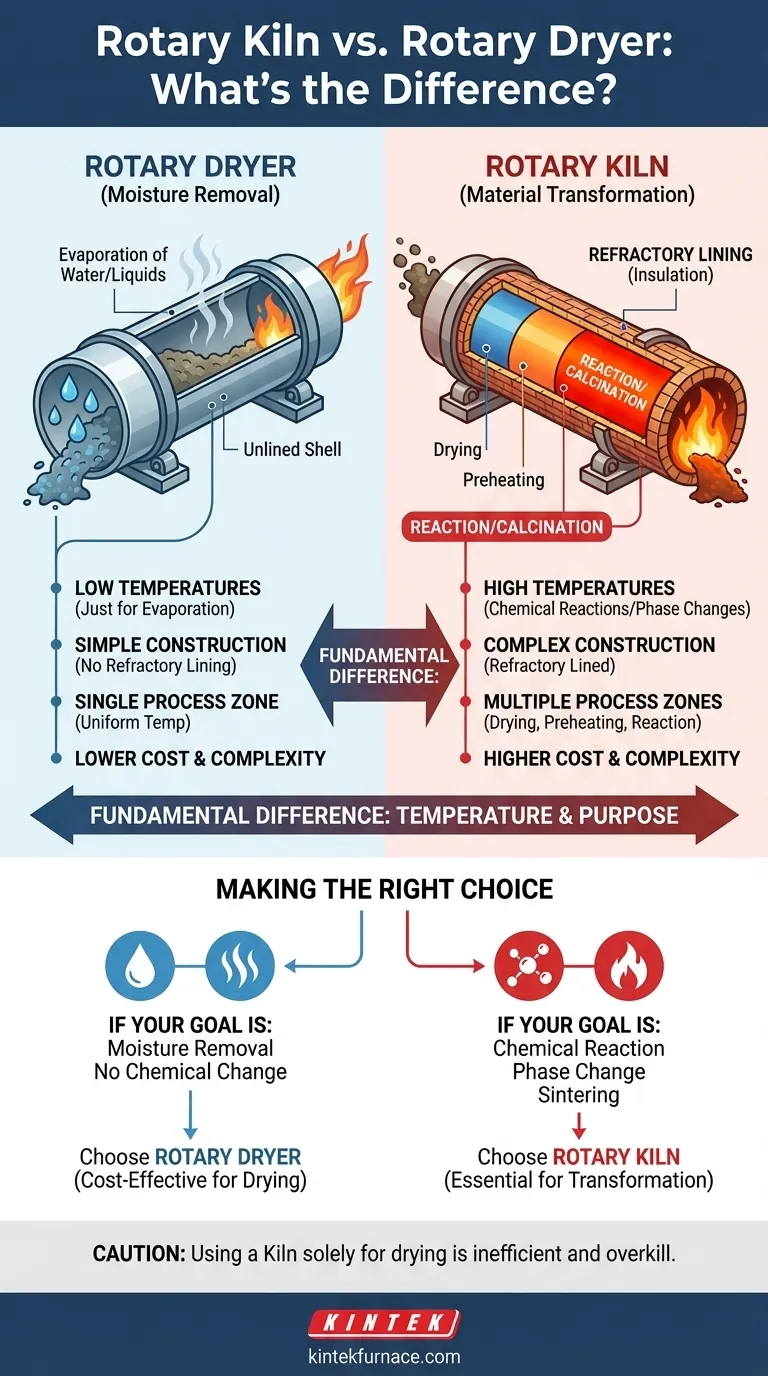

The Core Distinction: Temperature and Purpose

While both are rotating cylindrical vessels, their internal design and operating principles are tailored for vastly different thermal outcomes.

Rotary Dryers: The Goal is Moisture Removal

A rotary dryer's sole function is to evaporate water or other liquids from a solid material.

It operates at relatively low temperatures, just high enough to facilitate this evaporation without altering the material's chemical composition.

Because of these lower operating temperatures, dryers are often constructed without a protective internal lining, as the steel shell can withstand the heat.

Rotary Kilns: The Goal is Material Transformation

A rotary kiln is a high-temperature thermal processing tool. Its purpose is to heat materials to a point where a chemical reaction or phase change occurs.

This includes processes like calcination, where a material is thermally decomposed.

To withstand extreme temperatures, a kiln is always lined with refractory brick or castable refractory. This lining insulates the outer steel shell, which would otherwise fail.

Key Differences in Design and Operation

The different purposes of kilns and dryers lead to critical differences in their construction and how they function.

Heat Source and Transfer Method

Kilns and dryers can be direct-fired, where the material directly contacts the hot process gas, or indirect-fired, where the shell is heated externally.

However, kilns are designed to handle the intense, direct heat from powerful burners located at the discharge end, creating temperatures necessary for chemical reactions.

Materials of Construction (The Refractory Lining)

The single most important structural difference is the refractory lining. A kiln must have this protective layer to survive its high-temperature environment.

A dryer typically does not have a refractory lining, making it a simpler and less expensive piece of equipment to build and maintain.

Internal Process Zones

A rotary kiln is often engineered with distinct process zones. A material moving through it may pass through a drying zone, a preheating zone, and finally a high-temperature calcining or reaction zone.

A dryer, by contrast, functions essentially as one large drying zone with a more uniform temperature profile.

Understanding the Trade-offs

Choosing the wrong equipment leads to inefficiency, material damage, or process failure.

Cost and Complexity

A rotary kiln is significantly more complex and expensive to manufacture and operate than a rotary dryer. The refractory lining, high-output burner system, and robust structural supports all add to the cost.

Process Control

Controlling the process in a kiln is more demanding. It requires precise management of temperature, atmosphere, and material residence time to achieve the desired chemical reaction without over-processing the material.

Can a Kiln Be Used as a Dryer?

While a kiln can technically dry material in its initial zones, using it solely for drying is like using a surgical scalpel to spread butter. It is massive overkill, highly inefficient, and far more expensive to operate than a purpose-built rotary dryer.

Making the Right Choice for Your Process

Your decision must be driven entirely by the thermal task you need to accomplish.

- If your primary focus is simply removing moisture without altering the material's chemistry: A rotary dryer is the correct, most cost-effective tool.

- If your primary focus is to induce a chemical reaction, phase change, or sinter a material: You absolutely require a rotary kiln.

- If your material is sensitive to direct flame or combustion byproducts: An indirect-fired kiln, often called a calciner, is the appropriate choice.

Ultimately, selecting the right equipment begins with a clear understanding of your material and your desired end-product.

Summary Table:

| Feature | Rotary Dryer | Rotary Kiln |

|---|---|---|

| Primary Purpose | Moisture removal | Chemical reactions, phase changes |

| Operating Temperature | Low (for evaporation) | High (for transformation) |

| Internal Lining | Typically none | Refractory lining required |

| Cost and Complexity | Lower | Higher |

| Process Zones | Single drying zone | Multiple zones (e.g., drying, preheating, reaction) |

Need expert guidance for your thermal processing needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to optimize your process with the right equipment!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing