In simple terms, vacuum induction heating is an exceptionally efficient method for transferring energy directly into a conductive material. While some claims of 100% efficiency are theoretical overstatements, the process itself is remarkably direct, avoiding many of the heat losses found in conventional furnaces. However, its true overall efficiency is not a single number; it is highly dependent on the specific setup, material being heated, and the design of the induction system.

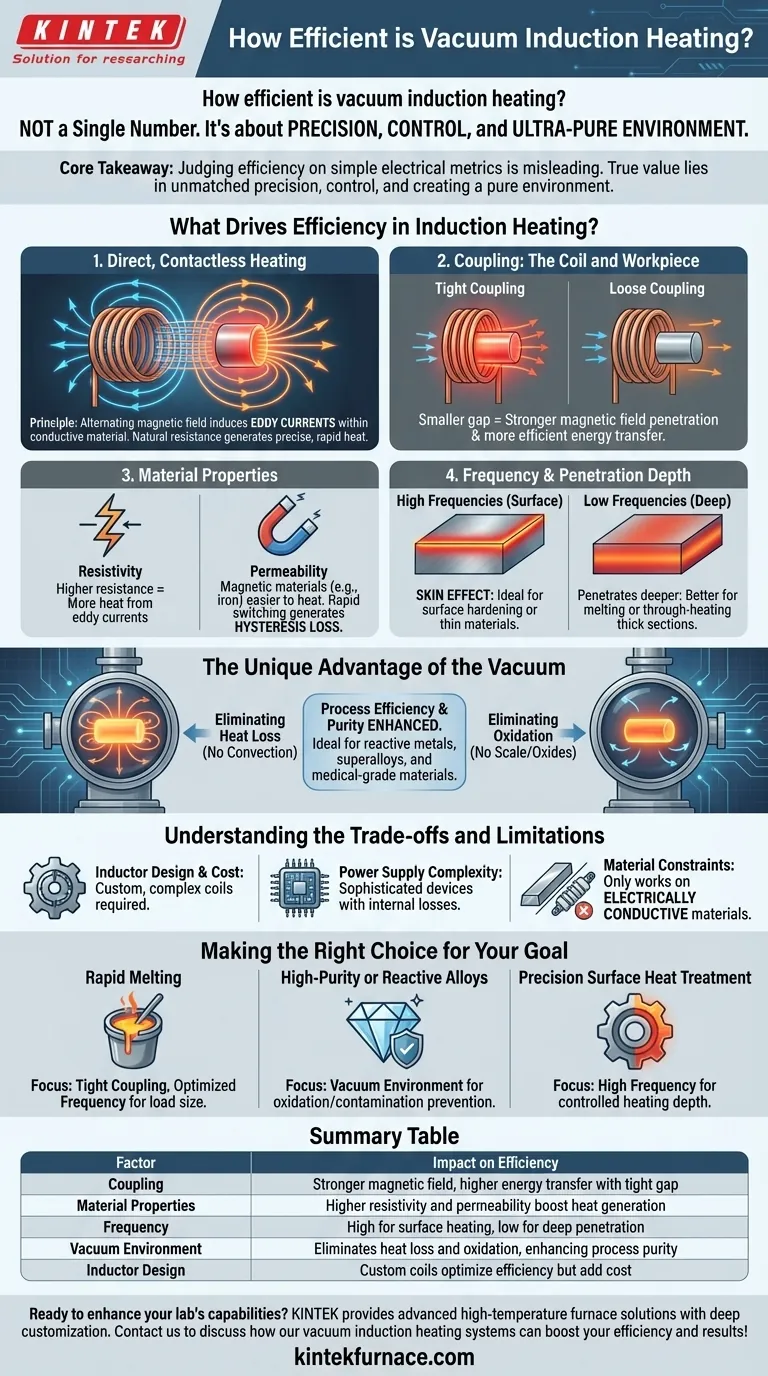

The core takeaway is that judging vacuum induction heating on a simple electrical efficiency metric is misleading. Its true value—and its "efficiency" in a practical sense—lies in its unparalleled precision, control, and ability to create an ultra-pure environment, which are often far more critical than minor variations in power consumption.

What Drives Efficiency in Induction Heating?

The efficiency of an induction heating system is determined by how well the magnetic field, generated by a coil, couples with the material you intend to heat. The vacuum itself doesn't change the physics of induction, but it profoundly impacts the overall process.

The Principle: Direct, Contactless Heating

Induction heating works by generating a powerful, alternating magnetic field from a copper coil. When a conductive workpiece (like a metal) is placed inside this field, the field induces electrical currents, known as eddy currents, within the metal itself. The material's natural resistance to these currents generates precise and rapid heat.

Coupling: The Coil and the Workpiece

The distance between the induction coil and the workpiece is one of the most critical factors. A smaller gap results in a stronger magnetic field penetrating the material, leading to a more efficient energy transfer. This is referred to as tight coupling.

Material Properties: Resistivity and Permeability

The material being heated plays a huge role.

- Resistivity: Higher electrical resistance leads to more heat generation from the eddy currents.

- Permeability: Magnetic materials, like iron, are much easier to heat. The rapid switching of their magnetic domains generates additional heat through a process called hysteresis loss, significantly boosting efficiency.

Frequency and Penetration Depth

The frequency of the alternating current (AC) is a key variable you can control. It determines how deeply the heat penetrates the material.

- High Frequencies: These create a "skin effect," concentrating heat on the surface. This is ideal for surface hardening or thin materials.

- Low Frequencies: These penetrate deeper into the workpiece, making them better for melting or through-heating thick cross-sections.

The Unique Advantage of the Vacuum

A vacuum environment enhances the process efficiency, which is often more important than the electrical efficiency alone.

Eliminating Heat Loss and Oxidation

In open air, a hot workpiece loses significant energy to the surrounding atmosphere through convection. A vacuum eliminates this heat loss path. More importantly, it removes oxygen, preventing the formation of scale and oxides, ensuring the material's purity is maintained.

Enabling Unmatched Control and Purity

The combination of precise energy control and a clean environment makes vacuum induction ideal for critical applications. It allows for the processing of reactive metals like titanium, superalloys, and medical-grade materials that would be contaminated if heated in air.

Understanding the Trade-offs and Limitations

While powerful, vacuum induction heating is not a universal solution. It comes with specific requirements and constraints.

Inductor Design and Cost

The induction coil, or inductor, must be carefully designed and engineered for each specific application and workpiece shape. These custom coils can be complex and expensive to manufacture, especially those requiring high current densities.

Power Supply Complexity

The specialized power supplies that generate the high-frequency currents are sophisticated electronic devices. They have their own internal energy losses, which contribute to the total system efficiency.

Material Constraints

The primary limitation of induction heating is that it only works on electrically conductive materials. It cannot be used to directly heat insulators like ceramics or polymers, though a conductive crucible can be heated to indirectly heat a non-conductive material.

Making the Right Choice for Your Goal

Your decision to use vacuum induction heating should be guided by your final objective, not just a theoretical efficiency percentage.

- If your primary focus is rapid melting of bulk metals: Concentrate on achieving tight coupling between the coil and the crucible, and select a frequency optimized for the size of your material load.

- If your primary focus is high-purity or reactive alloys: The prevention of oxidation and contamination offered by the vacuum environment is the most critical factor, far outweighing small differences in electrical efficiency.

- If your primary focus is precision surface heat treatment: Employ a high frequency to control the heating depth precisely, as this targeted energy application is the main benefit.

Ultimately, the true "efficiency" of vacuum induction heating is best measured by its ability to produce a superior product with unparalleled control, speed, and purity.

Summary Table:

| Factor | Impact on Efficiency |

|---|---|

| Coupling | Stronger magnetic field with tight coil-workpiece gap increases energy transfer |

| Material Properties | Higher resistivity and permeability boost heat generation |

| Frequency | High for surface heating, low for deep penetration |

| Vacuum Environment | Eliminates heat loss and oxidation, enhancing process purity |

| Inductor Design | Custom coils optimize efficiency but add cost |

Ready to enhance your lab's capabilities with precise and pure heating solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our vacuum induction heating systems can boost your efficiency and results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What is vacuum induction melting technology and why is it important? Achieve High-Purity Metals for Critical Applications