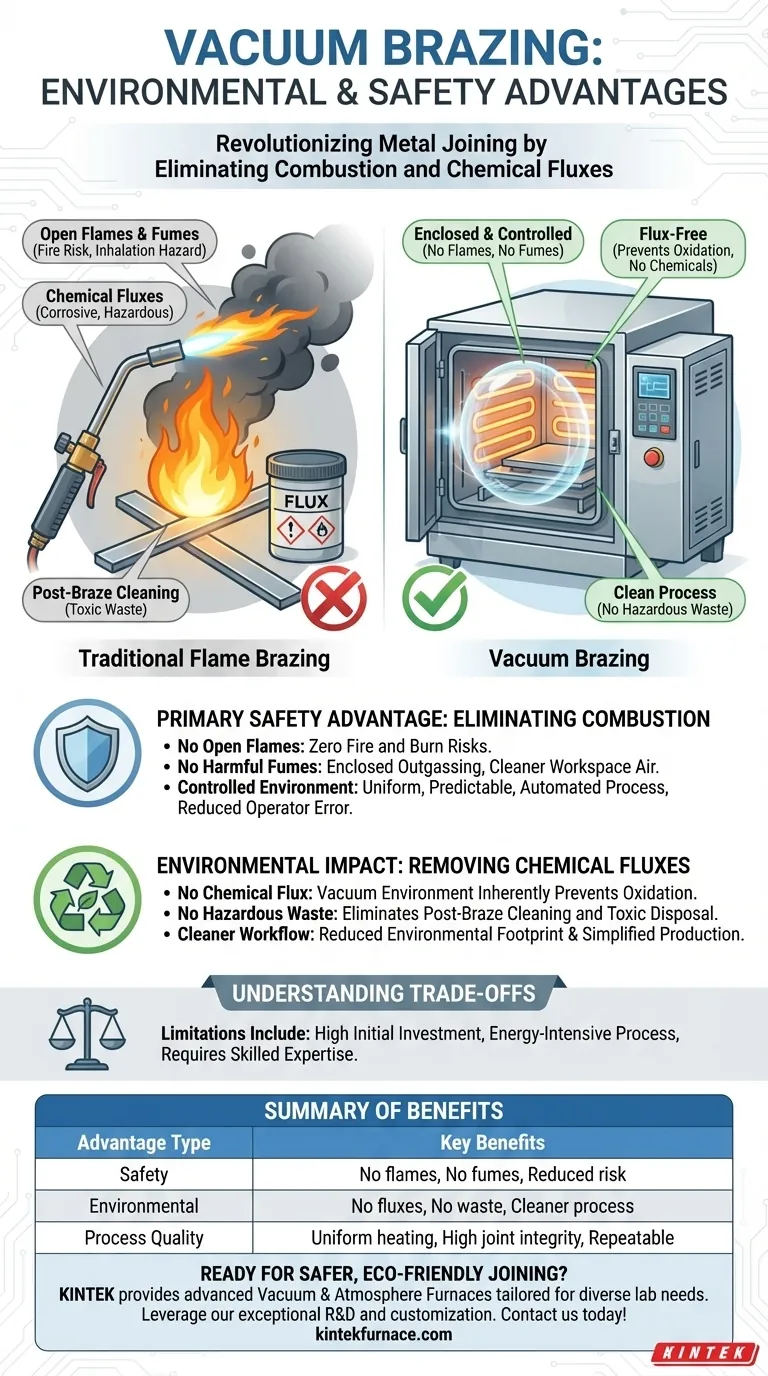

At its core, vacuum brazing provides significant environmental and safety advantages over traditional methods by fundamentally changing the joining environment. Instead of relying on an open flame and chemical cleaning agents, the process uses a controlled, enclosed vacuum that inherently prevents oxidation and eliminates the production of hazardous combustion by-products, creating a cleaner and safer operation from start to finish.

By removing both chemical fluxes and open-flame combustion from the equation, vacuum brazing directly addresses two of the biggest safety and environmental concerns associated with metal joining. This results in a cleaner workspace, less hazardous waste, and a more predictable, operator-safe process.

The Primary Safety Advantage: Eliminating Combustion

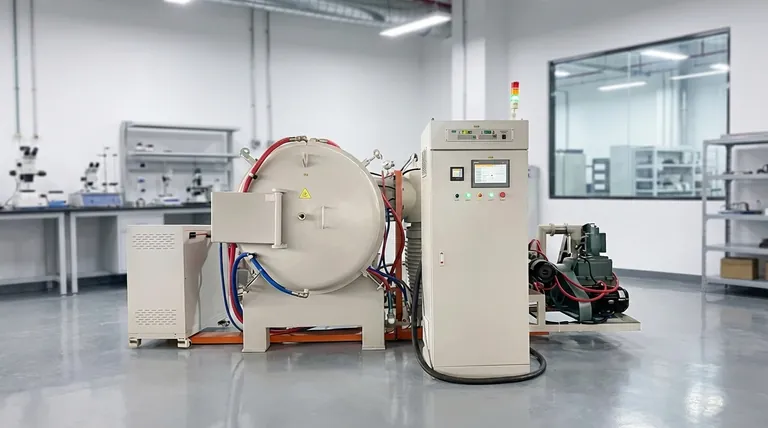

The most immediate safety benefit of vacuum brazing comes from moving the process away from an open flame and into a sealed, controlled furnace. This shift mitigates several critical workplace hazards.

No Open Flames or Fumes

Traditional flame brazing involves an open torch, which presents an obvious fire and burn risk. More importantly, it generates combustion by-products and fumes that can be harmful if inhaled by the operator.

Vacuum brazing occurs entirely within an enclosed furnace. This eliminates the risk of open flames and ensures that any outgassing from the materials is contained, not released into the workspace air.

A Controlled, Predictable Environment

Flame brazing relies heavily on operator skill to apply heat evenly, which can be inconsistent. In contrast, a vacuum furnace provides exceptionally uniform heating and cooling in a highly repeatable, automated cycle.

This controlled environment not only improves the quality of the joint but also makes the process far more predictable and less dependent on manual intervention, reducing the chances of operator error that could lead to a safety incident.

The Environmental Impact: Removing Chemical Fluxes

Beyond eliminating combustion, the vacuum environment itself provides a major environmental benefit by making chemical fluxes unnecessary.

The Problem with Traditional Flux

In most brazing processes, a flux—a chemical agent—is required to clean the metal surfaces and prevent oxidation so the filler metal can bond properly. These fluxes are often corrosive or hazardous.

After brazing, the flux residue must be thoroughly cleaned from the part, a step that often involves more chemicals and creates hazardous waste that requires special disposal.

How a Vacuum Replaces Flux

The vacuum in the furnace removes oxygen and other atmospheric gases from the chamber. By creating an atmosphere free of contaminants, the vacuum itself prevents oxidation on the metal parts as they are heated.

Because oxidation is prevented by the environment, there is no need for a chemical flux. The process is inherently cleaner, producing bright, shiny joints without chemical assistance.

Eliminating Post-Braze Cleaning Waste

Since no flux is used, there is no need for post-braze chemical cleaning. This directly reduces the use of hazardous materials and eliminates the downstream process of treating and disposing of chemical waste. It simplifies the entire production workflow while reducing its environmental footprint.

Understanding the Trade-offs

While vacuum brazing offers clear benefits, it is not the optimal solution for every scenario. Understanding its limitations is key to making an informed decision.

High Initial Investment

Vacuum furnaces represent a significant capital expenditure. For small-scale operations or prototyping, the cost can be prohibitive compared to the low entry cost of a simple flame-brazing torch setup.

Energy Consumption

Heating a large industrial furnace to temperatures between 800°C and 1150°C is an energy-intensive process. While it can be highly efficient for processing large batches of parts in a single cycle, the overall energy draw is a critical consideration for both cost and environmental impact.

Process Complexity and Expertise

Operating a vacuum furnace requires a deep understanding of metallurgy, thermodynamics, and process control. It is not a simple "plug-and-play" technology and demands skilled technicians to ensure proper setup, operation, and maintenance.

Making the Right Choice for Your Goal

Your choice of brazing method should align directly with your project's primary constraints and objectives.

- If your primary focus is workplace safety and environmental cleanliness: Vacuum brazing is the superior choice due to its enclosed, flux-free, and combustion-free nature.

- If your primary focus is minimizing initial cost for low-volume work: Traditional flame brazing is often more practical, but you must implement robust safety and waste-handling protocols to mitigate its risks.

- If your primary focus is achieving the highest joint integrity for critical components: Vacuum brazing is unmatched, as its clean and controlled environment is essential for aerospace, medical, and hydraulic applications.

Ultimately, adopting vacuum brazing is a strategic decision to prioritize process purity, safety, and repeatability over lower initial equipment cost.

Summary Table:

| Advantage Type | Key Benefits |

|---|---|

| Safety | No open flames, no harmful fumes, reduced operator error risk |

| Environmental | No chemical fluxes, no hazardous waste, eliminates post-braze cleaning |

| Process Quality | Uniform heating, repeatable results, high joint integrity |

| Trade-offs | High initial cost, energy-intensive, requires skilled operation |

Ready to elevate your metal joining with safer, eco-friendly solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for diverse laboratories. Our deep customization capabilities ensure we meet your unique experimental needs, helping you achieve superior results with reduced environmental impact. Contact us today to discuss how our vacuum brazing systems can benefit your operations!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?