The graphene skin produced via Fluidized Bed Chemical Vapor Deposition (FB-CVD) functions as a high-velocity thermal superhighway. By enveloping alumina particles in a continuous multi-layer graphene skin, the process creates highly efficient phonon pathways. This structure leverages the exceptional in-plane thermal conductivity of graphene to transport heat significantly faster than the pure alumina particles found in traditional fillers.

The FB-CVD process transforms standard filler particles by growing a conductive shell that facilitates strong phonon coupling. This allows heat to bypass the natural thermal resistance of the ceramic core, resulting in a dramatic increase in the overall thermal conductivity of the material.

The Mechanics of Enhanced Conductivity

Creating Efficient Phonon Pathways

In thermal interface materials, heat transfer is often limited by how effectively vibrational energy, known as phonons, moves through the solid.

The FB-CVD process addresses this by growing a continuous graphene skin. This skin acts as a dedicated, low-resistance lane for phonons to travel, preventing the thermal bottlenecks common in discontinuous materials.

Leveraging In-Plane Conductivity

Graphene is renowned for its exceptionally high in-plane thermal conductivity.

By coating the filler particles, the composite utilizes this property to move heat rapidly across the surface of the particle. This is far more efficient than forcing heat to traverse the bulk of a standard ceramic particle.

Strong Phonon Coupling

A critical factor in this performance is the interaction between the skin and the core.

There is strong phonon coupling between the graphene skin and the underlying alumina substrate. This ensures that heat energy is not scattered or lost at the interface but is instead seamlessly transferred into the high-speed graphene network.

Comparison to Traditional Fillers

Speed of Heat Flow

Traditional fillers often rely on pure alumina particles to conduct heat.

While alumina is a decent conductor, heat flow through pure alumina is significantly slower compared to the graphene-coated alternative. The graphene skin accelerates this process, acting as a turbocharger for the particle's thermal performance.

Structural Continuity

Standard fillers often suffer from contact resistance between particles.

The continuous multi-layer nature of the FB-CVD graphene skin helps mitigate this. It ensures a more consistent thermal network throughout the composite, rather than relying solely on the point-to-point contact of bare ceramic particles.

Understanding the Critical Dependencies

The Necessity of Continuity

The performance of this composite is entirely dependent on the "continuous" quality of the graphene skin.

If the FB-CVD process fails to produce a uniform coating, the high-efficiency phonon pathway is broken. Gaps in the skin would force heat back into the slower alumina core, negating the advantage.

Interface Quality

The "strong phonon coupling" mentioned is a requirement, not a guarantee.

For this material to outperform traditional fillers, the bond between the alumina and the graphene must be pristine. If the interface is weak, phonon scattering will occur, reducing the overall thermal conductivity regardless of the graphene's quality.

Making the Right Choice for Your Goal

When evaluating thermal interface materials, consider how the microstructure aligns with your thermal targets:

- If your primary focus is Maximum Heat Dissipation: Prioritize composites featuring FB-CVD grown graphene skins, as the continuous phonon pathways provide a conductivity ceiling significantly higher than pure alumina.

- If your primary focus is Overcoming Contact Resistance: Look for materials where "strong phonon coupling" is verified, ensuring the graphene skin effectively bridges the thermal gap between the filler and the matrix.

Ultimately, the superiority of this material lies in its ability to transform a standard ceramic filler into a rapid thermal network through surface engineering.

Summary Table:

| Feature | Traditional Alumina Fillers | FB-CVD Graphene-Coated Fillers |

|---|---|---|

| Heat Transfer Mechanism | Bulk conduction through ceramic | High-speed in-plane surface conduction |

| Thermal Pathway | Discontinuous/Point-to-point | Continuous multi-layer superhighway |

| Phonon Efficiency | High scattering at boundaries | Strong coupling & low-resistance flow |

| Conductivity Speed | Standard | Significantly Accelerated (Turbocharged) |

| Key Advantage | Cost-effective insulation | Maximum heat dissipation & low resistance |

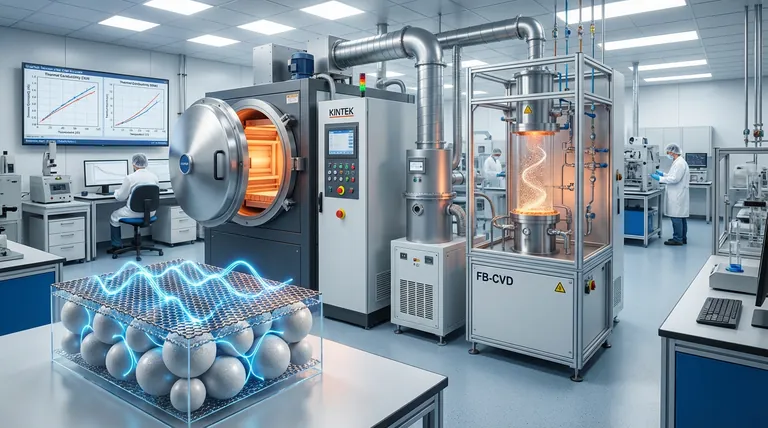

Revolutionize Your Material Performance with KINTEK

Elevate your research and production with KINTEK’s precision-engineered thermal solutions. As leaders in high-temperature laboratory technology, we provide the expert R&D and manufacturing capabilities needed to achieve superior material properties.

Whether you require FB-CVD systems, Muffle, Tube, Rotary, or Vacuum furnaces, our equipment is fully customizable to meet your unique graphene growth and composite engineering needs.

Ready to optimize your thermal interface materials? Contact our technical experts today to discover how KINTEK can enhance your lab’s efficiency and innovation.

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- How does vacuum heat treating affect the grain structure of metal alloys? Achieve Precise Microstructure Control

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity