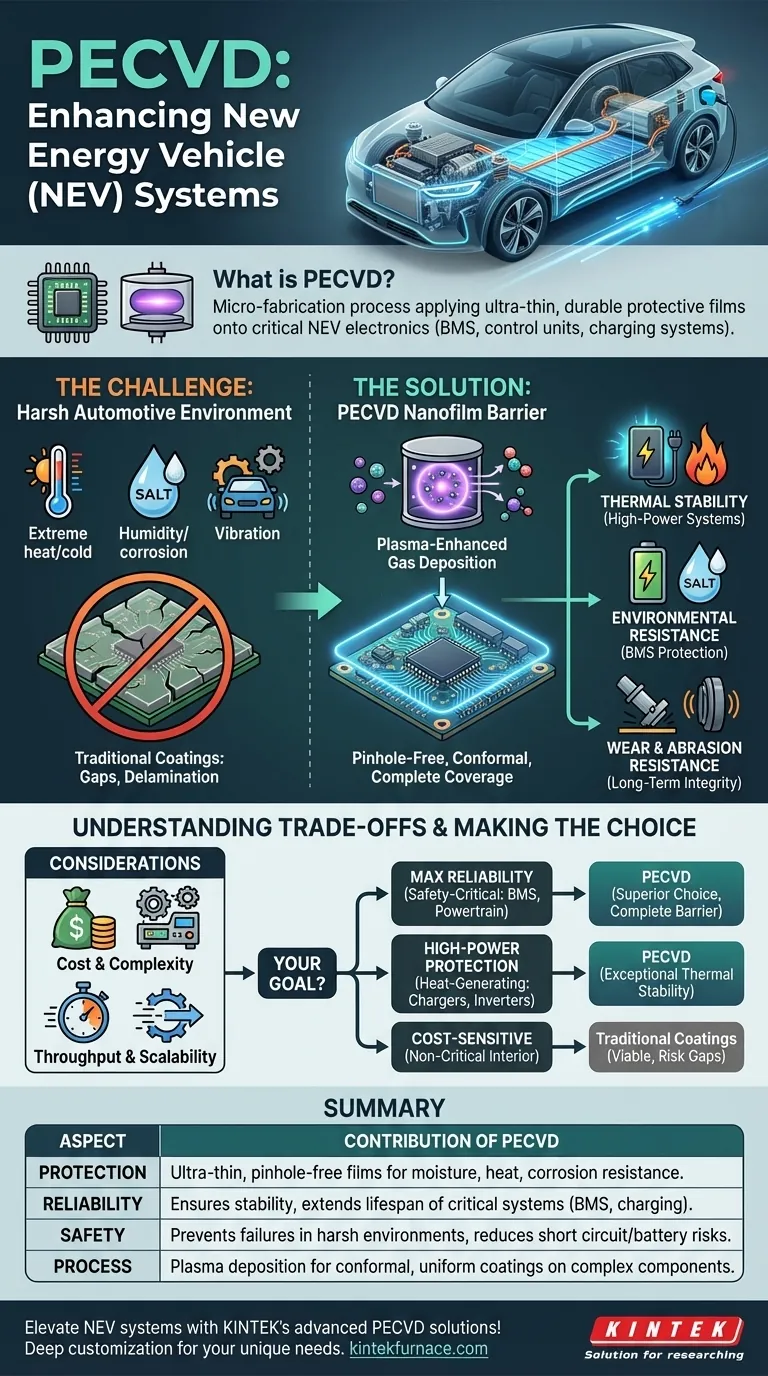

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a micro-fabrication process used to apply an ultra-thin, highly durable protective film onto critical electronic components in new energy vehicles. This nanofilm acts as a shield for systems like the Battery Management System (BMS), central control units, and high-power charging electronics. By providing robust protection against heat, moisture, and wear, PECVD directly enhances the operational stability, safety, and lifespan of the entire vehicle.

The central challenge for new energy vehicle electronics is surviving a harsh operating environment of extreme temperatures, humidity, and vibration. PECVD provides a uniquely effective solution by creating a complete, pinhole-free protective barrier at a microscopic level, ensuring the reliability of the vehicle's most sensitive systems where traditional coatings often fail.

The Challenge: Protecting a Vehicle's Electronic Nervous System

The electronics in a new energy vehicle (NEV) are fundamentally different from consumer electronics. They are safety-critical components that must perform flawlessly for years under exceptionally demanding conditions.

The Harsh Automotive Environment

A vehicle's electronic circuit boards are constantly exposed to rapid temperature swings, from freezing cold to the intense heat generated by batteries and high-power charging systems. They must also resist humidity, road salt, and constant vibration.

Limitations of Traditional Coatings

Conventional protective methods, such as sprayed-on conformal coatings or epoxy potting, can be effective but have inherent weaknesses. They can be thick, add weight, suffer from incomplete coverage on complex circuit board topographies, and may delaminate over time, creating points of failure.

The Need for Micro-Scale Protection

As electronic components become smaller, more densely packed, and more complex, the need for a precise, thin, and perfectly uniform protective layer becomes paramount. A microscopic flaw in the protective barrier of a BMS, for example, could lead to a catastrophic battery failure.

How PECVD Provides Superior Protection

PECVD is not simply a coating; it's a deposition process that builds a protective film one molecular layer at a time. This allows for unparalleled control and performance.

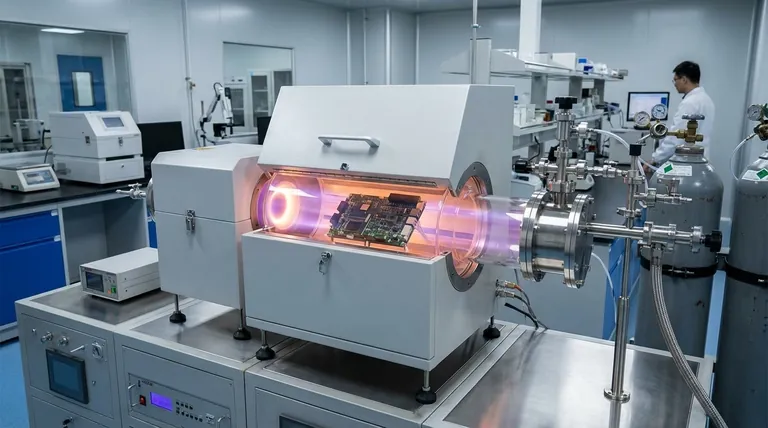

Creating the Nanofilm Barrier

In a vacuum chamber, specific gases are introduced and energized into a plasma. This reactive gas then decomposes and deposits onto the electronic components as an exceptionally thin, dense, and uniform polymer film. This conformal coating perfectly replicates the surface of even the most intricate circuits, leaving no gaps or weak points.

Thermal Stability for High-Power Systems

Components in boost charging systems and power inverters generate significant heat. PECVD films offer outstanding thermal stability, preventing a breakdown of the protective barrier and ensuring the electronics operate reliably under high thermal loads.

Environmental and Corrosion Resistance

The nanofilm created by PECVD is a powerful barrier against moisture and corrosive agents like salt. This is especially critical for the Battery Management System (BMS), where even a minor short circuit caused by moisture ingress could compromise battery health and vehicle safety.

Wear and Abrasion Resistance

The deposited film is highly durable and wear-resistant, protecting sensitive components and solder joints from damage caused by constant micro-vibrations inherent in a moving vehicle. This enhances the long-term mechanical integrity of the electronic assembly.

Understanding the Trade-offs

While highly effective, PECVD is a specialized process with specific considerations. Objectivity requires acknowledging its place among other technologies.

Process Complexity and Cost

PECVD is a vacuum deposition technology that requires significant capital investment in equipment and expertise. Compared to simple atmospheric spray or dip-coating processes, it is more complex and generally has a higher initial cost.

Throughput and Scalability

Batch processing in a vacuum chamber can have lower throughput than continuous, in-line coating methods. For extremely high-volume, low-cost electronics, this can be a limiting factor.

Material Selection

The choice of precursor gas and process parameters is critical. These must be carefully selected to ensure the resulting film has the desired protective properties without negatively impacting or damaging the underlying electronic components.

Making the Right Choice for Your Goal

Selecting the appropriate protection strategy depends entirely on the specific application's requirements for reliability, cost, and performance.

- If your primary focus is maximum reliability for safety-critical systems (like a BMS or powertrain controller): PECVD is the superior choice for its complete, pinhole-free conformal barrier.

- If your primary focus is protecting high-power, heat-generating electronics (like chargers and inverters): The exceptional thermal stability and moisture resistance of PECVD films are essential for ensuring long-term performance.

- If your primary focus is cost-sensitive protection for non-critical interior electronics: Traditional spray coatings may be a viable alternative, but you must accept the risk of potential gaps in coverage.

By understanding PECVD as a tool for engineering reliability at the microscopic level, you can make an informed decision to fundamentally enhance the safety and longevity of your new energy vehicle systems.

Summary Table:

| Aspect | Contribution of PECVD |

|---|---|

| Protection | Creates ultra-thin, pinhole-free films for moisture, heat, and corrosion resistance. |

| Reliability | Ensures operational stability and extends lifespan of critical systems like BMS and charging electronics. |

| Safety | Prevents failures in harsh environments, reducing risks of short circuits and battery issues. |

| Process | Uses plasma deposition for conformal, uniform coatings on complex components. |

Elevate your new energy vehicle systems with KINTEK's advanced PECVD solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces and CVD/PECVD systems tailored for diverse laboratories. Our deep customization capabilities ensure precise protection for your unique experimental needs, enhancing reliability and safety. Contact us today to discuss how our expertise can benefit your projects!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films