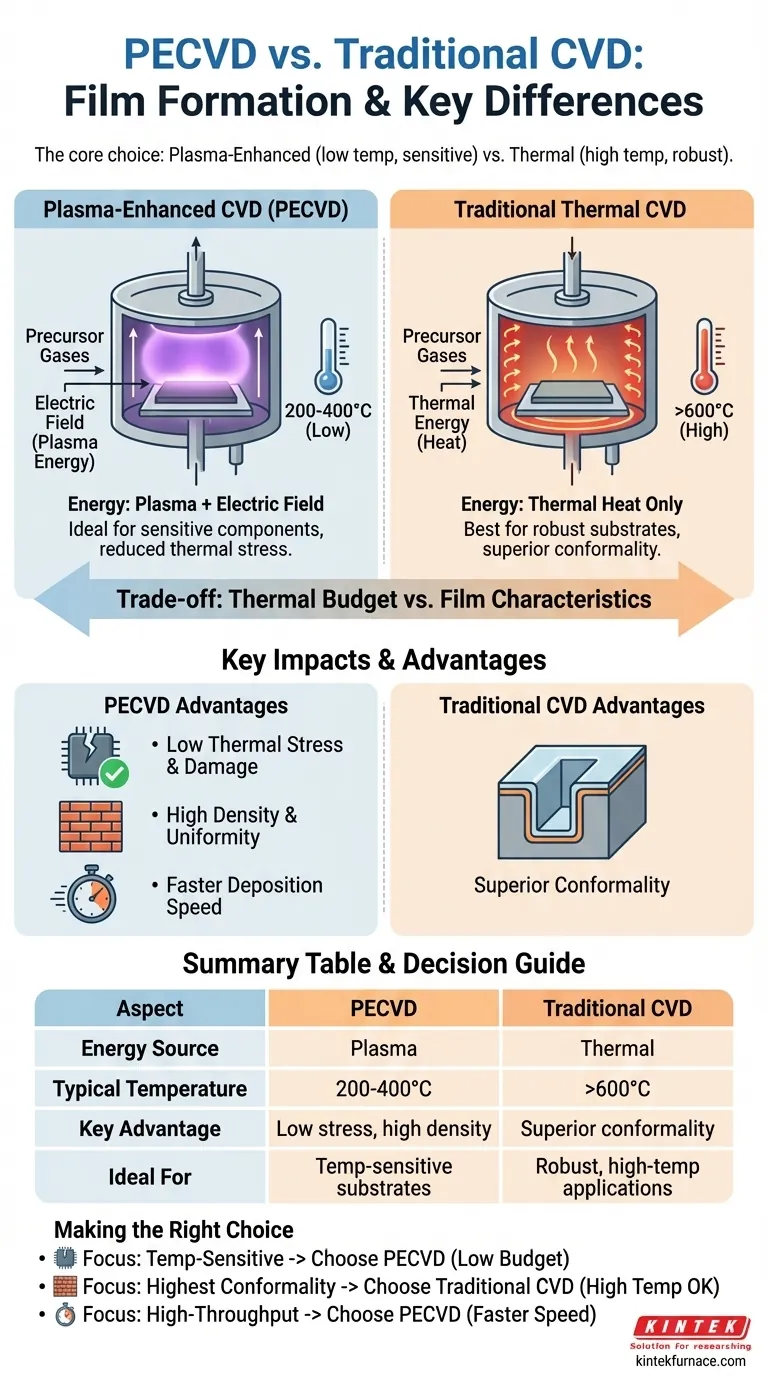

In essence, PECVD uses plasma to form high-quality films at much lower temperatures than traditional CVD. This fundamental difference makes Plasma-Enhanced Chemical Vapor Deposition (PECVD) ideal for fabricating modern, multi-layered devices where high heat would cause damage. In contrast, traditional Chemical Vapor Deposition (CVD) relies solely on high thermal energy, which limits its application to more robust substrates.

The core decision between PECVD and traditional CVD is a trade-off between the process's thermal budget and the required film characteristics. PECVD prioritizes low-temperature processing for sensitive components, while traditional CVD is chosen when high temperatures are acceptable and specific film properties, like conformality, are paramount.

The Fundamental Difference: Energy Source

The choice between these two methods comes down to how each process supplies the energy needed to initiate the chemical reaction that forms the film.

Traditional CVD: The Thermal Approach

Traditional CVD relies exclusively on thermal energy. Precursor gases are introduced into a high-temperature chamber (often >600°C), and the heat provides the activation energy to break down the gas molecules and deposit a solid film onto the substrate.

This method is effective but its high-temperature requirement is a significant limitation.

PECVD: The Plasma-Enhanced Approach

PECVD introduces an additional energy source: plasma. By applying an electric field to the precursor gases, an ionized gas or plasma is created within the reaction chamber.

This plasma provides the energy needed to break apart the precursor molecules, allowing the deposition reaction to occur at significantly lower substrate temperatures (typically 200-400°C). The substrate itself does not need to be intensely heated.

Impact on Film Properties and Process

This difference in energy sources has direct consequences for the final film and the overall manufacturing process.

Lower Thermal Stress and Damage

The most critical advantage of PECVD is its low processing temperature. This prevents damage to previously deposited layers or underlying circuitry, which is essential for creating complex integrated circuits.

It also dramatically reduces thermal stress in the deposited film, which helps prevent cracking and improves adhesion.

Film Quality and Density

Because the reaction is driven by energetic plasma rather than just heat, PECVD can produce films that are highly dense, uniform, and have fewer pinholes compared to some low-temperature thermal CVD processes.

While high-temperature traditional CVD can also yield excellent films, it runs the risk of introducing defects due to thermal stress or lattice mismatch with the underlying substrate.

Faster Deposition Speed

PECVD processes generally achieve faster deposition rates than their traditional thermal counterparts. The plasma-enhanced reaction is more efficient, allowing more material to be deposited in less time, which is a major benefit for high-volume manufacturing.

Understanding the Trade-offs

While PECVD's low-temperature advantage is significant, it is not universally superior. Choosing the right method requires understanding the compromises.

The Temperature Budget Constraint

The primary reason to choose PECVD is when your substrate or existing device layers cannot withstand high temperatures. If your process has a strict "thermal budget," PECVD is often the only viable option.

The Conformality Challenge

Traditional thermal CVD often provides superior conformality, meaning it can evenly coat complex, three-dimensional structures with high aspect ratios. The non-directional nature of a thermally driven process helps the film grow uniformly over steps and inside trenches.

Plasma-based deposition can be more directional, sometimes resulting in poorer "step coverage" on very complex topographies.

Film Purity and Composition

In some specialized cases, the high energy of the plasma can cause unintended side reactions or implant ions into the film, potentially affecting purity. A well-controlled traditional thermal CVD process can sometimes produce a film with a slightly different and more desirable chemical stoichiometry for a specific application.

Making the Right Choice for Your Application

Your decision should be guided by the non-negotiable requirements of your specific project.

- If your primary focus is protecting temperature-sensitive structures: Choose PECVD for its low thermal budget, which is essential for multi-layer semiconductor devices.

- If your primary focus is achieving the highest conformality on complex topographies: Traditional CVD is often the better choice, provided the substrate can tolerate the required high temperatures.

- If your primary focus is high-throughput manufacturing: PECVD's faster deposition rates offer a significant advantage for process efficiency.

By understanding the core trade-off between thermal energy and plasma energy, you can confidently select the deposition method that best aligns with your fabrication goals.

Summary Table:

| Aspect | PECVD | Traditional CVD |

|---|---|---|

| Energy Source | Plasma | Thermal |

| Typical Temperature | 200-400°C | >600°C |

| Key Advantage | Low thermal stress, high density | Superior conformality |

| Ideal For | Temperature-sensitive substrates | Robust, high-temperature applications |

Need expert advice on choosing the right CVD solution for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD systems. Our deep customization capability ensures we precisely meet your unique experimental requirements, whether you're working with semiconductors, multi-layer devices, or other sensitive applications. Contact us today to enhance your fabrication process with tailored, efficient equipment!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What is PECVD equipment? A Guide to Low-Temperature Thin-Film Deposition

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition

- What gases are used in the PECVD system? Optimize Thin Film Deposition with Precise Gas Selection

- How is silicon dioxide (SiO2) used in PECVD applications? Key Roles in Microfabrication