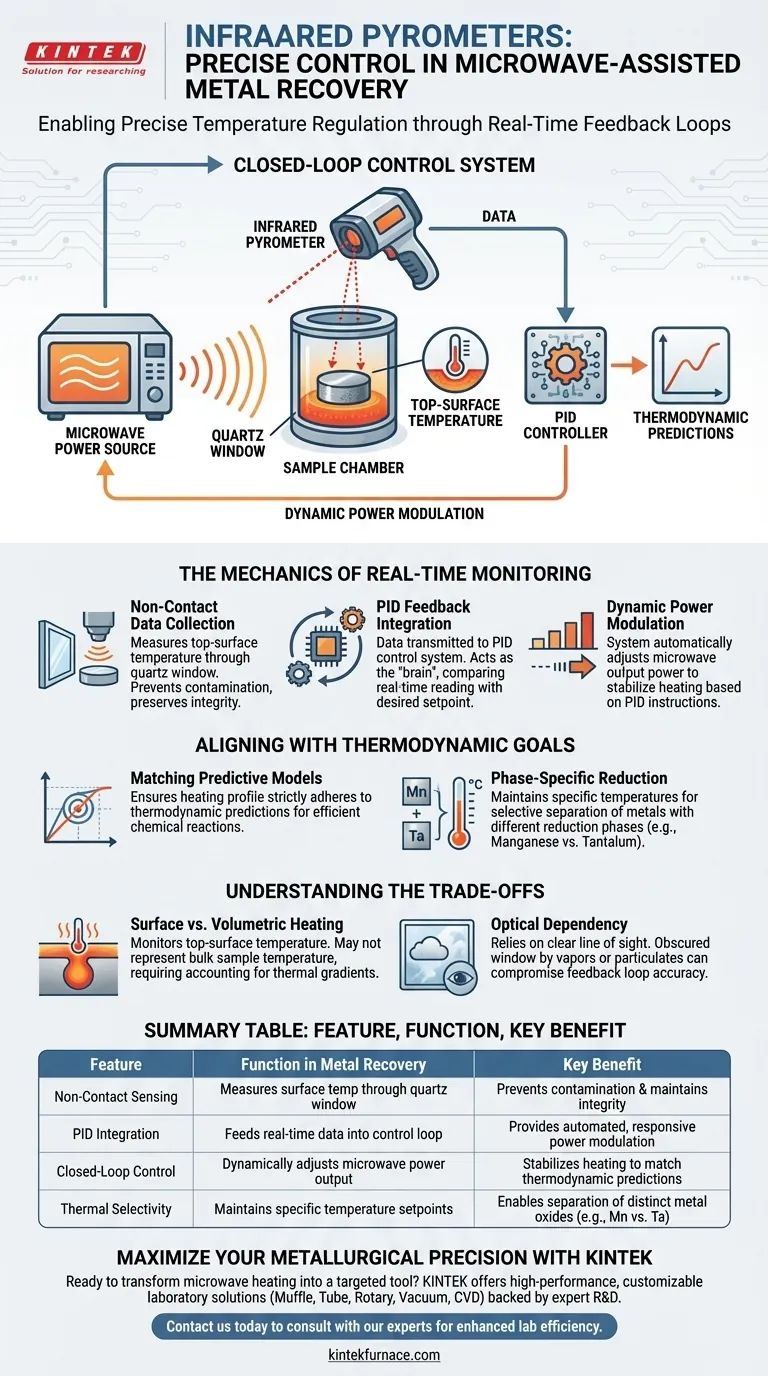

An infrared pyrometer enables precise temperature regulation by acting as the critical sensor in a real-time feedback loop. It measures the top-surface temperature of a sample through a quartz window without physical contact, providing the immediate data necessary to modulate the microwave power source.

By feeding real-time thermal data into a PID control system, the pyrometer establishes a "closed-loop" process. This ensures the heating profile strictly adheres to thermodynamic predictions, allowing for the selective separation of metals with different reduction phases.

The Mechanics of Real-Time Monitoring

Non-Contact Data Collection

The system utilizes an infrared pyrometer to monitor the top-surface temperature of the metal sample.

Because the measurement is taken through a quartz window, the sensor never physically touches the sample. This non-contact approach preserves the integrity of the microwave environment while capturing accurate thermal data.

The PID Feedback Integration

The temperature signal collected by the pyrometer is immediately transmitted to a PID (Proportional-Integral-Derivative) control system.

This controller acts as the "brain" of the operation. It constantly compares the real-time temperature reading against the desired setpoint to calculate the necessary adjustments.

Dynamic Power Modulation

Based on instructions from the PID controller, the system dynamically adjusts the output power of the microwave source.

If the temperature lags, power increases; if it overshoots, power is throttled. This creates a responsive closed-loop control system that stabilizes the process automatically.

Aligning with Thermodynamic Goals

Matching Predictive Models

The primary goal of this control loop is to ensure the actual heating profile aligns with thermodynamic predictions.

Without this feedback, microwave heating can be erratic. The pyrometer ensures the temperature follows a specific, pre-calculated curve essential for chemical reactions.

Phase-Specific Reduction

Precise control allows operators to manage distinct stages of the recovery process.

For example, the system can maintain specific temperatures required for the reduction of manganese oxides while avoiding or targeting the temperatures needed for tantalum oxides. This thermal selectivity is vital for efficient metal separation.

Understanding the Trade-offs

Surface vs. Volumetric Heating

The pyrometer specifically monitors the top-surface temperature.

While effective, this reading may not always represent the temperature deep within the bulk of the sample. Operators must account for potential thermal gradients between the surface and the core.

Optical Dependency

The system relies on a clear line of sight through the quartz window.

If the window becomes obscured by vapors or particulate matter during the metal recovery process, the accuracy of the feedback loop could be compromised.

Making the Right Choice for Your Goal

To maximize the efficiency of microwave-assisted metal recovery, align your control settings with your specific metallurgical targets.

- If your primary focus is Process Stability: Ensure the PID parameters are tuned to react quickly to the pyrometer's data to prevent thermal runaway.

- If your primary focus is Selective Separation: Use the closed-loop control to lock into the precise thermodynamic window required for specific oxides, such as separating manganese from tantalum.

Precise thermal management transforms microwave heating from a broad application into a targeted tool for metallurgical separation.

Summary Table:

| Feature | Function in Metal Recovery | Key Benefit |

|---|---|---|

| Non-Contact Sensing | Measures surface temp through a quartz window | Prevents contamination and maintains microwave integrity |

| PID Integration | Feeds real-time data into a control loop | Provides automated, responsive power modulation |

| Closed-Loop Control | Dynamically adjusts microwave power output | Stabilizes heating to match thermodynamic predictions |

| Thermal Selectivity | Maintains specific temperature setpoints | Enables separation of distinct metal oxides (e.g., Mn vs. Ta) |

Maximize Your Metallurgical Precision with KINTEK

Ready to transform your microwave heating into a targeted tool for metal recovery? Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance laboratory solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique thermal processing needs.

Our advanced equipment ensures the precise temperature regulation required for complex selective separation and thermodynamic stability. Contact us today to consult with our experts and discover how KINTEK can enhance your lab's efficiency and process control.

Visual Guide

References

- Ansan Pokharel, Terence Musho. Microwave-assisted recycling of tantalum and manganese from end-of-life tantalum capacitors. DOI: 10.1038/s41598-025-96574-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What key functions do high-strength graphite molds perform? Optimize Al2O3/TiC Hot Press Sintering Success

- What are the advantages of using high-purity platinum crucibles? Ensure Absolute Data Integrity in Magnetite Oxidation

- How does the use of Matched Thermal Baffles (MTB) benefit directional solidification? Achieve Superior Crystal Integrity

- What is the significance of using a vacuum saturation device for AAS concrete? Ensure Valid Chloride Ion Testing

- What is the primary function of a radiation pyrometer in validating furnace simulations? Ensure Model Accuracy

- What is the necessity of a cylindrical condenser in a microwave-assisted metal reduction system? Key Protection Insights

- Why is a vacuum suction system required during the exhaust stage of rice straw-based charcoal carbonization?

- What is the purpose of using fused quartz tubes in high-temperature sealed reaction systems for alloy research?