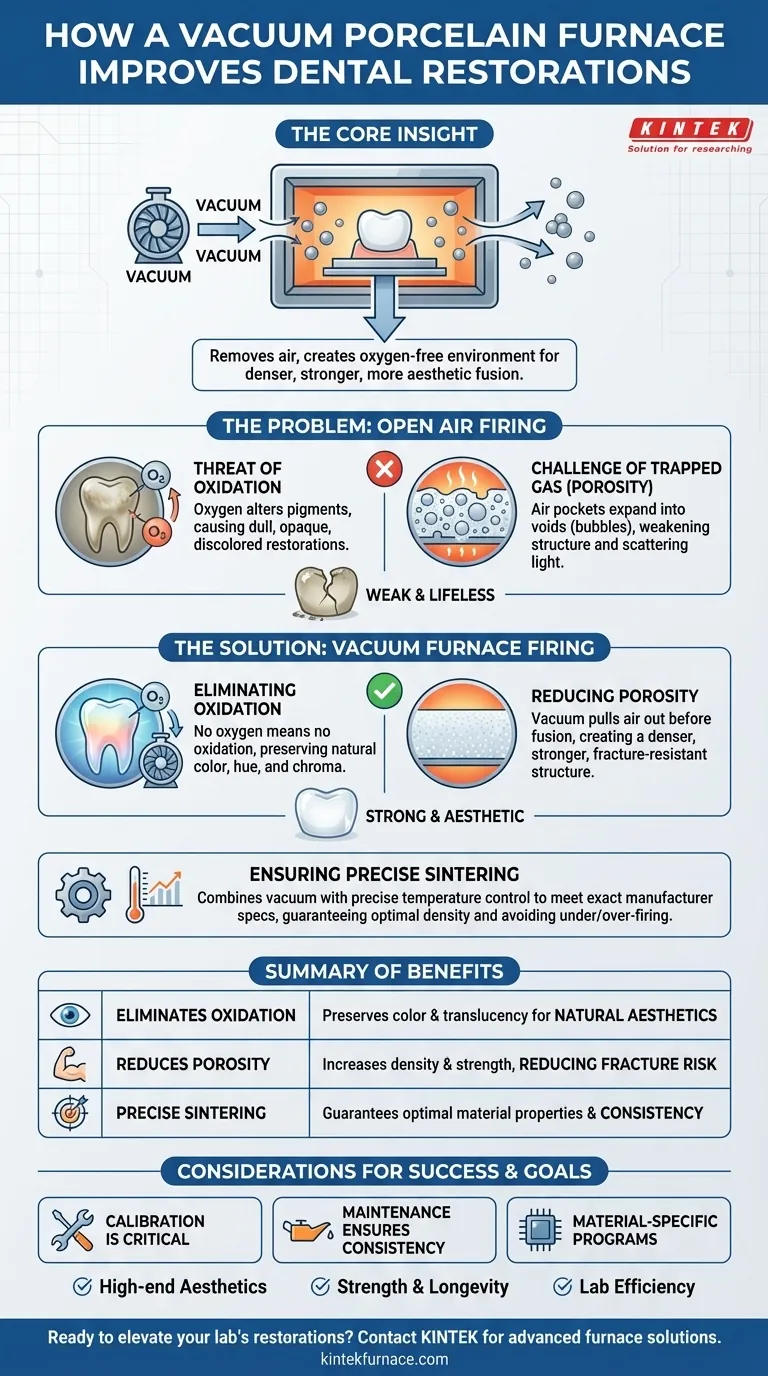

At its core, a vacuum porcelain furnace improves dental restorations by removing air from the firing chamber. This controlled, oxygen-free environment is the key to preventing common defects, allowing the ceramic material to fuse into a structure that is denser, stronger, and more aesthetically pleasing than what can be achieved in a conventional, air-filled oven.

The crucial insight is that the vacuum itself is an active tool in the firing process. It's not just about applying heat; it's about removing atmospheric gases that would otherwise compromise the ceramic's integrity, leading to bubbles, discoloration, and structural weakness.

The Problem with Firing Ceramics in Open Air

To understand the value of a vacuum, we must first recognize the problems caused by firing dental porcelain in a normal atmosphere.

The Threat of Oxidation

Air contains oxygen, which is highly reactive at high temperatures. When ceramic materials are fired in its presence, oxidation can occur.

This reaction chemically alters the pigments and materials within the porcelain, often resulting in a dull, opaque, or discolored restoration that fails to match the patient's natural teeth.

The Challenge of Trapped Gas

Dental porcelain begins as a fine powder. When layered and prepared for firing, tiny pockets of air become trapped between the individual particles.

When heated in a conventional oven, this trapped air expands and forms bubbles, or voids, within the final restoration. This phenomenon is known as porosity.

The Impact of Porosity

These internal voids act as stress points, significantly weakening the final crown or veneer and making it more prone to fracture.

Furthermore, these bubbles scatter light, reducing the material's translucency and creating an artificial, lifeless appearance.

How a Vacuum Furnace Solves These Problems

A vacuum furnace directly counteracts the issues of oxidation and porosity by fundamentally changing the firing environment.

Eliminating Oxidation for Superior Aesthetics

By pumping the air out of the chamber, the furnace creates a vacuum that removes the oxygen.

Without oxygen, destructive oxidation cannot occur. This allows the ceramic to sinter and fuse while preserving its intended color, hue, and chroma, resulting in vibrant, natural-looking aesthetics.

Reducing Porosity for Increased Strength

The vacuum actively helps pull the trapped air out from between the porcelain particles before the material reaches its melting point and fuses together.

This leads to a much denser, less porous final structure. A denser ceramic is a stronger ceramic, better able to withstand the functional forces of the oral environment.

Ensuring Precise Sintering

Modern furnaces combine this vacuum capability with highly precise temperature control.

This precision ensures the ceramic is heated and cooled according to the exact parameters specified by the manufacturer. This guarantees the material reaches its optimal density and strength without being over- or under-fired.

Understanding the Trade-offs and Considerations

While essential for quality, a vacuum furnace is a precision instrument that requires proper management to deliver its benefits.

Calibration is Critical

A furnace is only as good as its calibration. Inaccurate temperature readings or a weak vacuum can lead to failed restorations, wasting time and materials. Regular calibration is non-negotiable.

Maintenance Ensures Consistency

The vacuum pump, chamber seals, and heating muffle are all wear components. A failure in any of these parts can compromise the vacuum and ruin the work. A strict maintenance schedule is essential for consistent results.

Material-Specific Programs are Required

Different types of ceramics (e.g., feldspathic, lithium disilicate) have unique firing schedules. Using the wrong program, even in a perfect furnace, will produce a poor-quality restoration. The technician's knowledge is just as important as the equipment.

Making the Right Choice for Your Goal

By understanding these principles, you can leverage a vacuum furnace to achieve specific clinical and business objectives.

- If your primary focus is high-end aesthetics: The vacuum's ability to prevent oxidation is your most important tool for achieving natural translucency and color stability, especially for anterior cases.

- If your primary focus is strength and longevity: The vacuum's role in reducing porosity is key to creating dense, fracture-resistant crowns and bridges that will last for years.

- If your primary focus is lab efficiency: A well-maintained vacuum furnace delivers predictable outcomes, drastically reducing costly remakes and ensuring consistent quality across all cases.

Mastering the vacuum firing process is fundamental to transforming simple ceramic powder into a strong, beautiful, and lasting dental restoration.

Summary Table:

| Benefit | How It Works | Impact on Restoration |

|---|---|---|

| Eliminates Oxidation | Removes oxygen from the chamber during firing | Preserves color and translucency for natural aesthetics |

| Reduces Porosity | Pulls trapped air out before fusion | Increases density and strength, reducing fracture risk |

| Ensures Precise Sintering | Combines vacuum with accurate temperature control | Guarantees optimal material properties and consistency |

Ready to elevate your dental lab's restorations? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides advanced high-temperature furnace solutions tailored for dental professionals. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Achieve superior quality with fewer remakes—contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations