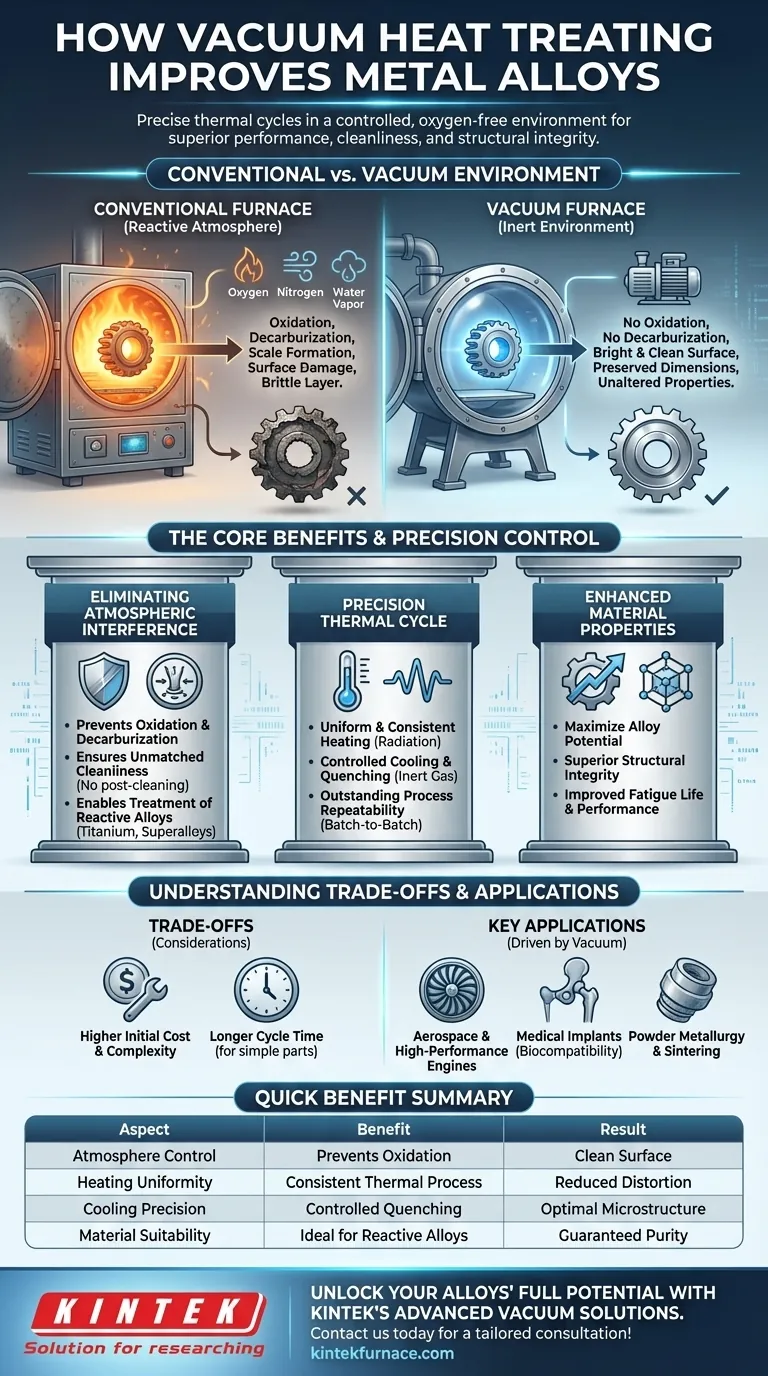

At its core, a vacuum heat treating furnace improves metal alloys by executing a precise thermal cycle in a controlled, oxygen-free environment. This process prevents unwanted chemical reactions like oxidation, ensures exceptionally uniform heating and cooling, and allows for the creation of components with superior cleanliness, structural integrity, and performance characteristics.

While conventional furnaces treat metal in the presence of reactive atmospheric gases, a vacuum furnace removes this variable entirely. This fundamental shift from a reactive to an inert environment is what unlocks the ability to process high-performance alloys to their maximum theoretical potential, achieving properties unattainable through other methods.

The Core Principle: Eliminating Atmospheric Interference

The primary advantage of a vacuum furnace is the removal of the atmosphere, which is normally full of reactive gases like oxygen, nitrogen, and water vapor. This creates a chemically clean slate for thermal processing.

Preventing Oxidation and Decarburization

At high temperatures, oxygen aggressively reacts with most metals, forming a brittle, flaky layer of scale known as an oxide layer. This damages the surface finish and can alter the dimensions of a precision part.

Similarly, carbon can be stripped from the surface of steel alloys in a process called decarburization, which softens the material and reduces its fatigue life. A vacuum environment completely prevents both of these detrimental reactions.

Ensuring Unmatched Cleanliness

Because oxidation is prevented, parts emerge from a vacuum furnace with a bright, clean, and scale-free surface. This often eliminates the need for post-treatment cleaning operations like sandblasting or acid pickling, saving time and resources while preserving the component's pristine surface.

Enabling Treatment of Reactive Alloys

Certain materials are extremely sensitive to atmospheric contamination. Titanium, superalloys, and specific nickel alloys will readily react with oxygen and nitrogen at elevated temperatures, compromising their mechanical properties. Vacuum treatment is the only viable method to process these materials without causing contamination.

Precision Control Over the Entire Thermal Cycle

Beyond providing a clean environment, vacuum furnaces offer unparalleled control over every stage of the heat treatment process.

Uniform and Consistent Heating

Vacuum furnaces utilize radiation as the primary mode of heat transfer, which provides extremely uniform heating across the entire workpiece, even for complex geometries. This consistency prevents thermal stresses, minimizes distortion, and ensures that the desired metallurgical properties are achieved evenly throughout the part.

Controlled Cooling and Quenching

After heating, locking in the desired microstructure often requires rapid cooling, or quenching. Vacuum furnaces can perform this step with high precision by backfilling the chamber with a high-pressure inert gas like argon or nitrogen. This allows for rapid, yet highly controlled, cooling without the distortion risks associated with liquid quenching.

Process Repeatability

The combination of a controlled atmosphere and digital temperature regulation leads to outstanding process stability and repeatability. For critical applications in aerospace or medicine, the ability to produce identical parts batch after batch is non-negotiable, and vacuum furnaces excel at this.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not a universal solution. Understanding its limitations is key to making an informed decision.

Cost and Complexity

Vacuum furnaces represent a significant capital investment compared to traditional atmospheric furnaces. They also require more complex operational procedures and maintenance, including managing vacuum pumps and ensuring chamber integrity.

Cycle Time

The need to pump down the chamber to the required vacuum level adds time to the beginning of each cycle. For high-volume production of simple parts, this can make the overall cycle time longer than in a continuous atmospheric furnace.

It Is Not Always Necessary

For simple, low-carbon steel parts where a thin oxide layer is acceptable or can be easily removed, the benefits of vacuum treatment may not justify the added cost and complexity. Standard atmospheric furnaces are often sufficient for these less demanding applications.

Key Applications Driven by Vacuum Processing

The unique capabilities of vacuum furnaces make them indispensable for manufacturing the most advanced components in modern industry.

Aerospace and High-Performance Engines

The processing of superalloys and titanium alloys for turbine blades, engine components, and structural airframe parts relies on vacuum furnaces. The process guarantees the purity and structural integrity required to withstand extreme temperatures and stresses.

Medical Implants

Materials used for medical implants, such as titanium and cobalt-chrome alloys, must be biocompatible and free of any surface contaminants. Vacuum heat treatment delivers the required cleanliness and optimal mechanical properties for devices like hip and knee replacements.

Powder Metallurgy and Sintering

Vacuum sintering is used to fuse metal powders—such as tungsten and molybdenum—into solid, dense components. The vacuum ensures a uniform grain structure and prevents contamination, creating hard metals used in military, research, and high-tech industrial applications.

Making the Right Choice for Your Application

Selecting the right thermal process depends entirely on your material, your performance requirements, and your budget.

- If your primary focus is maximum performance and purity: For critical applications in aerospace, medical, or nuclear industries using reactive alloys, vacuum treatment is non-negotiable.

- If your primary focus is high-alloy or tool steels: Vacuum provides superior results by preventing decarburization, ensuring maximum hardness and component life.

- If your primary focus is cost-sensitive, low-alloy components: Where minor surface oxidation is acceptable, traditional atmospheric treatment is often the more economical choice.

Ultimately, choosing vacuum heat treatment is a decision to prioritize metallurgical perfection over process simplicity.

Summary Table:

| Aspect | Benefit |

|---|---|

| Atmosphere Control | Prevents oxidation and decarburization for clean, scale-free surfaces |

| Heating Uniformity | Ensures consistent thermal processing, reducing distortion and stress |

| Cooling Precision | Allows controlled quenching with inert gases for optimal microstructure |

| Material Suitability | Ideal for reactive alloys like titanium and superalloys, ensuring purity |

| Process Repeatability | Delivers reliable results for critical applications in batch production |

Unlock the full potential of your metal alloys with KINTEK's advanced vacuum heat treating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing performance, purity, and efficiency. Ready to elevate your processes? Contact us today for a tailored consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity