In a vacuum furnace, heat exchange occurs almost exclusively through thermal radiation. Because a vacuum removes the air molecules necessary for convection and conduction, heat must travel from the heating elements to the workpiece via electromagnetic waves, similar to how the sun heats the Earth. This process allows for highly controlled and clean heating, as the workpiece is isolated from reactive gases.

A vacuum furnace fundamentally alters heat transfer by eliminating air. This forces heat to move via radiation, providing a pure, uniform, and highly controllable environment ideal for treating sensitive materials without contamination.

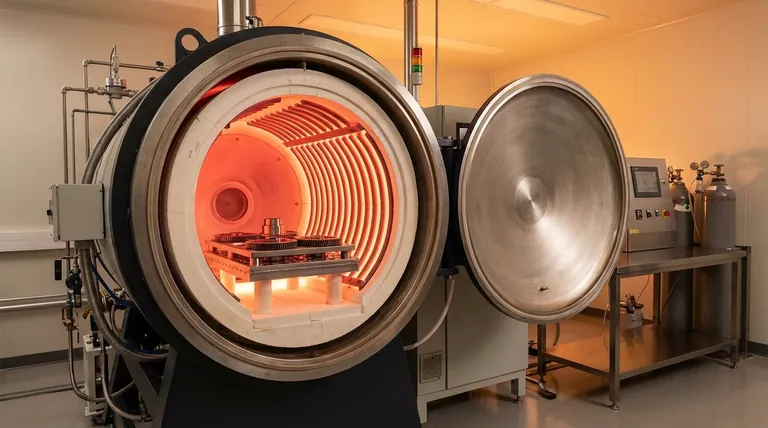

The Fundamental Principle: Heating in a Void

To understand how a vacuum furnace works, you must first understand why the vacuum is necessary. The environment dictates the method of heat transfer.

Why a Vacuum? Eliminating Convection and Contamination

The primary purpose of a vacuum is to remove air and other gases from the heating chamber. This has two critical effects.

First, it prevents oxidation and contamination. Many materials, especially at high temperatures, will react with oxygen or other elements in the air, damaging their surface and properties. A vacuum provides an ultra-clean environment.

Second, it eliminates convection. Convection is heat transfer through the movement of fluids (like air). By removing the air, convection currents cannot form, giving the operator precise control over the heating process.

The Dominance of Thermal Radiation

With convection gone, thermal radiation becomes the dominant method of heat transfer.

All objects with a temperature above absolute zero emit thermal energy as electromagnetic waves (primarily in the infrared spectrum). Hotter objects radiate more energy than colder ones.

In a vacuum furnace, heating elements become extremely hot and radiate this energy in all directions. The workpiece, being cooler, absorbs this radiated energy, causing its temperature to rise. This transfer requires no physical medium.

Common Heating Methods in Vacuum Furnaces

While radiation is the method of transfer, the source of that heat can vary depending on the furnace design and its intended application.

Internal Resistance Heaters

This is the most common design for general heat treatment. Heating elements made of materials like graphite or molybdenum are placed inside the vacuum chamber, surrounding the workpiece.

When electricity passes through these elements, they heat up and glow, radiating thermal energy directly onto the load. Their 360-degree placement ensures uniform heating from all sides.

External Heaters (Retort Furnaces)

In a "hot wall" or retort furnace, the heating elements are located outside the sealed vacuum chamber (the retort).

The elements first heat the walls of the retort. The hot walls then radiate thermal energy inward to heat the workpiece inside. This design protects the heating elements from the process environment.

Induction Heating

This specialized method uses electromagnetic fields. A coil outside the chamber generates a powerful alternating magnetic field that passes through the vacuum.

This field induces electrical currents within the workpiece itself (or a conductive crucible holding it), causing it to heat up rapidly from within. The workpiece then becomes its own heat source, radiating energy.

The Overlooked Roles of Conduction and Gas

While radiation is dominant, other mechanisms play smaller but important roles.

Limited Role of Conduction

Conduction—heat transfer through direct contact—still occurs. The workpiece heats up where it touches the support fixtures or trays inside the furnace. However, this accounts for a very small percentage of the total heat transfer.

Gas for Convective Cooling

Paradoxically, gas is crucial for the cooling part of the cycle. Once the workpiece has been held at the target temperature, the heating elements are turned off.

To cool it down quickly and uniformly, an inert gas like nitrogen or argon is introduced into the chamber. This gas "backfill" re-enables convection, allowing fans to circulate the gas and efficiently remove heat from the part.

Understanding the Trade-offs

The unique physics of vacuum heating create specific advantages and challenges.

The Challenge of Line-of-Sight

Radiation travels in straight lines. If a part of the workpiece is "shadowed" by another part or by the fixture, it may not receive direct radiation and will heat more slowly. Proper furnace design and load arrangement are critical to ensure all surfaces are evenly heated.

Temperature Uniformity

While radiation enables excellent final temperature uniformity, it can be less efficient at lower temperatures. As a result, the initial ramp-up can sometimes be slower than in a furnace that uses convection.

System Complexity and Cost

Vacuum furnaces are inherently more complex than standard atmosphere furnaces. They require a system of pumps to create the vacuum, robust seals to maintain it, and sophisticated controls, all of which add to their cost and maintenance requirements.

How to Apply This to Your Process

Choosing the right heating method depends entirely on your material and desired outcome.

- If your primary focus is high-purity annealing, brazing, or hardening: A furnace with internal resistance heaters is the standard, as it provides clean, uniform radiative heating essential for preventing oxidation.

- If your primary focus is rapid sintering of powdered metals: A vacuum induction furnace is often the most efficient choice, as it heats the material directly and quickly.

- If your primary focus is melting reactive metals like titanium: A specialized vacuum arc furnace or vacuum induction melter is required to provide intense heat while protecting the molten metal from contamination.

By forcing heat to travel via radiation, a vacuum furnace gives you ultimate control over the thermal processing environment.

Summary Table:

| Aspect | Key Details |

|---|---|

| Heat Transfer Method | Primarily thermal radiation, with minimal conduction and gas-assisted cooling. |

| Common Heating Sources | Internal resistance heaters (graphite/molybdenum), external heaters (retort), induction heating. |

| Key Advantages | Prevents oxidation, provides uniform heating, ideal for sensitive materials. |

| Applications | Annealing, brazing, hardening, sintering, melting reactive metals like titanium. |

Unlock Precision in Your Laboratory with KINTEK's Advanced Vacuum Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need clean, controlled heating for annealing, brazing, or hardening, our vacuum furnaces ensure superior performance and reliability. Contact us today to discuss how we can enhance your thermal processing and deliver tailored solutions for your specific needs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control