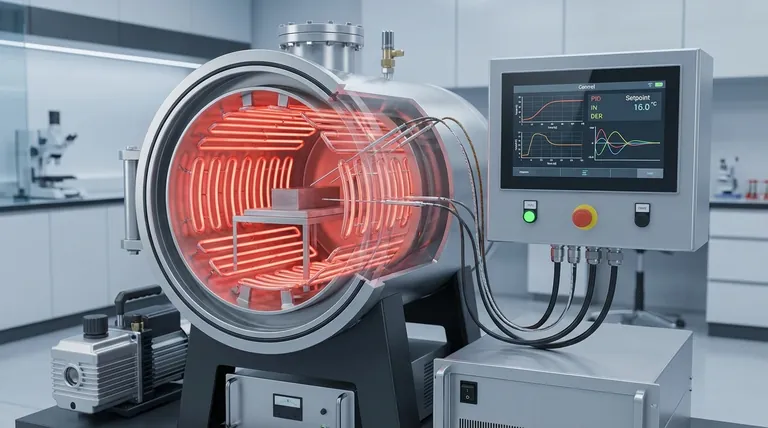

At its core, a vacuum annealing furnace achieves precise temperature control through a sophisticated closed-loop system. This system combines real-time temperature measurement, intelligent control algorithms to predict and correct deviations, and an advanced heating element design to ensure uniform heat distribution throughout the entire chamber.

A vacuum furnace doesn't just heat a chamber; it dynamically manages thermal energy. Its precision comes from a constant feedback loop: high-accuracy sensors measure the temperature, an intelligent controller calculates any error, and the heating system makes immediate, calculated adjustments to maintain a stable, uniform environment.

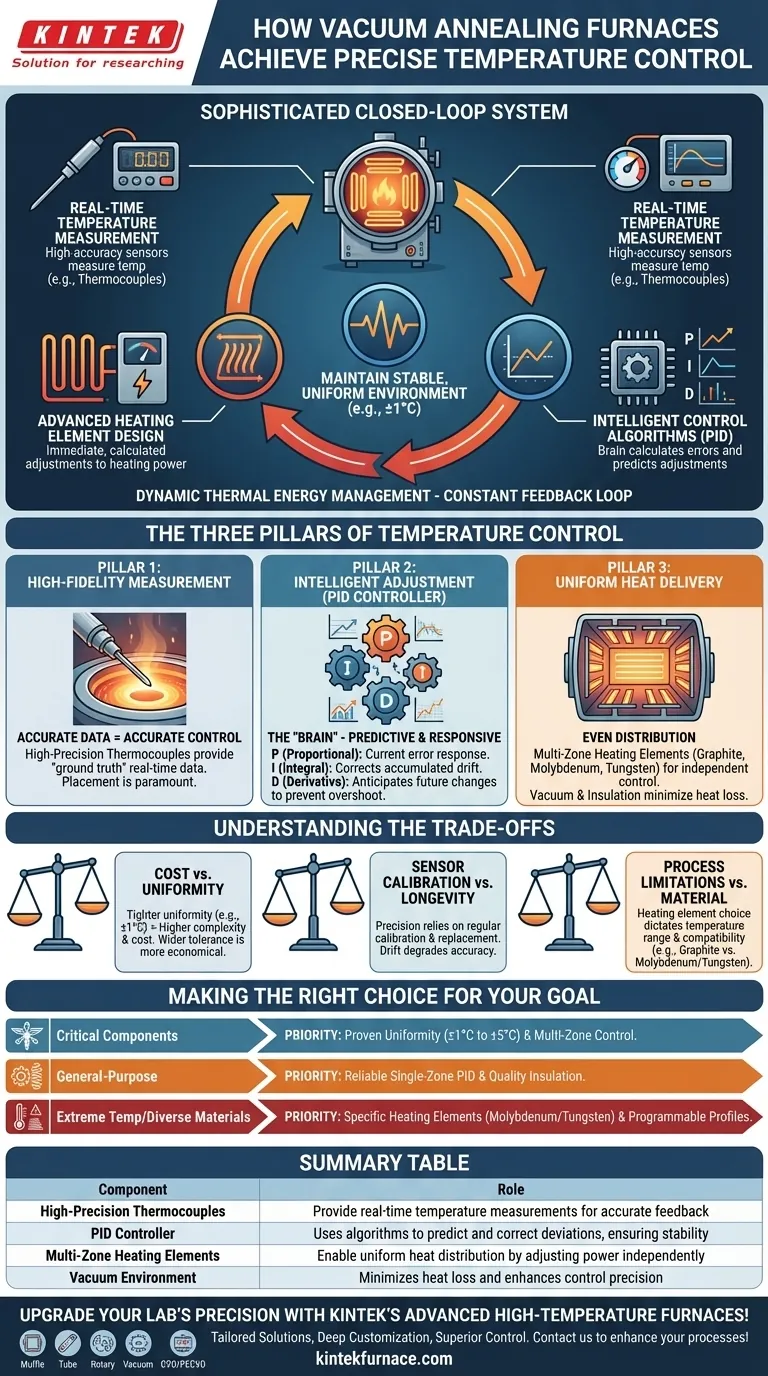

The Three Pillars of Temperature Control

Achieving temperature uniformity as tight as ±1°C is not the result of a single component, but rather the seamless integration of three critical subsystems.

Pillar 1: High-Fidelity Measurement

The control system can only be as accurate as the data it receives. This is the role of temperature sensors.

Modern furnaces use high-precision thermocouples placed strategically within the heating zone. These devices measure the temperature in real time and convert it into an electrical signal.

The accuracy and placement of these sensors are paramount. They provide the "ground truth" that the entire control system relies on to make adjustments.

Pillar 2: Intelligent Adjustment (The PID Controller)

The signal from the thermocouples is sent to the "brain" of the furnace: an intelligent temperature controller.

This controller almost always uses a PID (Proportional-Integral-Derivative) algorithm. This isn't simple on/off control; it's a predictive and responsive method for managing heating power.

- Proportional (P): Adjusts power based on the current difference between the actual temperature and the desired setpoint. A bigger difference means a stronger response.

- Integral (I): Corrects for small, steady-state errors by looking at the accumulated error over time. It eliminates the minor drift that proportional control alone can't fix.

- Derivative (D): Anticipates future temperature changes by looking at the rate of change. This helps prevent overshooting the setpoint, a critical factor for sensitive materials.

This combination allows the controller to react swiftly to fluctuations while also preventing the temperature from oscillating around the target.

Pillar 3: Uniform Heat Delivery

Precise control is meaningless if the heat isn't distributed evenly. This is solved through advanced heating system design.

Furnaces use high-performance electric heating elements made from materials like graphite, molybdenum, or tungsten, chosen based on the required temperature range (from 800°C up to 2400°C).

Crucially, these elements are often arranged into multiple, independently controllable heating zones. The PID controller can adjust power to each zone separately, compensating for potential cold spots and ensuring exceptional temperature uniformity across the entire workload.

Finally, high-efficiency insulation and the vacuum environment itself minimize heat loss, creating a stable thermal chamber where the control system can work effectively.

Understanding the Trade-offs

While the goal is always precision, the level of precision required involves practical considerations.

Cost vs. Uniformity

Achieving extremely tight temperature uniformity, such as ±1°C, requires more complex systems with multi-zone control and more sophisticated controllers. This directly increases the furnace's cost and complexity. For less critical applications, a wider tolerance may be perfectly acceptable and more economical.

Sensor Calibration and Longevity

Thermocouples can drift over time, especially at very high temperatures. The furnace's precision is entirely dependent on regular calibration and eventual replacement of these sensors. Neglecting this maintenance will degrade the system's accuracy.

Process Limitations

The choice of heating element material dictates the furnace's capabilities. Graphite is common, but in certain vacuum conditions, molybdenum or tungsten are required for higher temperatures or to prevent carbon contamination of the parts being treated.

Making the Right Choice for Your Goal

The level of temperature control you need depends entirely on your process and material requirements.

- If your primary focus is critical components (aerospace, medical): You must prioritize a system with documented temperature uniformity (e.g., ±1°C to ±5°C) and multi-zone heating control.

- If your primary focus is general-purpose stress relief or annealing: A standard furnace with a reliable single-zone PID controller and quality insulation will deliver consistent and repeatable results.

- If your primary focus is processing diverse materials at extreme temperatures: Your selection criteria should focus on the heating element material (molybdenum or tungsten) and a controller with highly programmable thermal profiles.

Ultimately, understanding this control system empowers you to select and operate a furnace that delivers consistent, high-quality results for your specific application.

Summary Table:

| Component | Role in Temperature Control |

|---|---|

| High-Precision Thermocouples | Provide real-time temperature measurements for accurate feedback |

| PID Controller | Uses algorithms to predict and correct deviations, ensuring stability |

| Multi-Zone Heating Elements | Enable uniform heat distribution by adjusting power independently |

| Vacuum Environment | Minimizes heat loss and enhances control precision |

Upgrade your lab's precision with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior temperature control and efficiency. Contact us today to discuss how we can enhance your processes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions