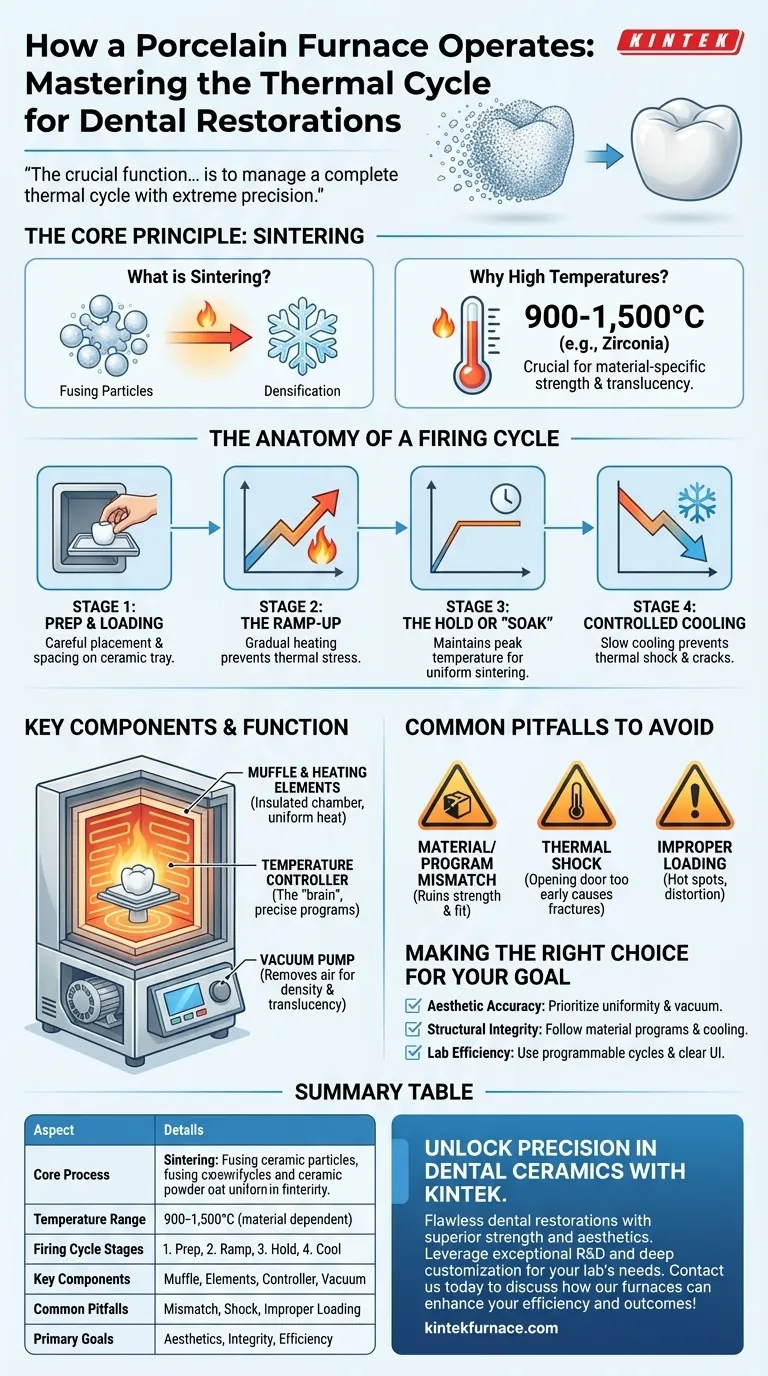

At its core, a porcelain furnace operates by applying precisely controlled heat to dental ceramic materials. This process, known as sintering, transforms loose ceramic particles into a solid, durable, and aesthetically pleasing restoration, such as a crown or veneer. The furnace executes a specific, pre-programmed cycle of heating, holding (soaking), and cooling to achieve these results without causing cracks or distortion.

The crucial function of a porcelain furnace isn't merely to get hot, but to manage a complete thermal cycle with extreme precision. The success of a dental restoration depends entirely on a controlled journey through high temperatures, not just the destination.

The Core Principle: Sintering

What is Sintering?

Sintering is the fundamental process happening inside the furnace. At high temperatures, the individual particles of the ceramic powder begin to fuse together, reducing the empty space between them.

This densification process is what gives the final restoration its strength and translucency. Think of it like tightly packing snowflakes until they form a solid piece of ice; the furnace does this with ceramic particles under intense heat.

Why High Temperatures are Necessary

Dental ceramics require very high temperatures to sinter properly. The exact temperature depends entirely on the material being used.

Traditional feldspathic porcelains may fire around 900-1000°C, while modern high-strength materials like zirconia require temperatures approaching 1,500°C (2,700°F). Using the wrong temperature for a given material will result in a failed restoration.

The Anatomy of a Firing Cycle

A furnace doesn't just turn on and off. It follows a meticulous, multi-stage program to ensure the ceramic is processed correctly.

Stage 1: Preparation and Loading

Before the cycle begins, the un-fired restoration is carefully placed on a ceramic support tray within the furnace's chamber, or muffle.

Proper spacing is critical. Pieces placed too close together will not heat evenly, leading to inconsistent sintering and potential distortion.

Stage 2: The Ramp-Up

The furnace begins to increase its temperature gradually. This slow "ramp-up" prevents thermal stress on the ceramic, which could otherwise cause it to crack before it even reaches peak temperature.

Stage 3: The Hold or "Soak"

Once the target temperature is reached, the furnace will hold it constant for a specific period. This "soaking" phase ensures that the entire restoration is heated uniformly and allows the sintering process to complete fully.

Stage 4: Controlled Cooling

After the soak, the furnace begins to cool down. This is arguably as critical as the heating phase. Cooling must be gradual to prevent thermal shock—a primary cause of cracking and structural failure in freshly fired ceramics.

Key Components and Their Function

The firing cycle is managed by a few essential components working in unison.

The Muffle and Heating Elements

The muffle is the insulated heating chamber that holds the dental work. It's designed for uniform heat distribution. The heat itself is generated by powerful heating elements, often made from materials like molybdenum disilicide, which can withstand repeated, extreme temperature cycles.

The Temperature Controller

This is the "brain" of the furnace. Modern furnaces use digital controllers that allow technicians to select or create precise, pre-programmed firing cycles for different ceramic materials. This ensures perfect repeatability.

The Vacuum Pump

Many furnaces include a vacuum system. During the heating cycle, a vacuum is pulled to remove air from within the ceramic particles. This results in a denser, stronger, and more translucent final restoration by eliminating microscopic bubbles or voids.

Common Pitfalls to Avoid

Even with advanced technology, user error can compromise the outcome. Understanding these pitfalls is key to consistent success.

Material and Program Mismatch

The single most common error is using a firing program that does not perfectly match the manufacturer's specifications for the specific ceramic being used. This can ruin the restoration's strength, fit, and color.

The Risk of Thermal Shock

Opening the furnace door too early to speed up cooling is a critical mistake. This sudden temperature drop will almost certainly cause microscopic or even visible fractures in the ceramic, leading to failure in the patient's mouth.

Improper Loading

Placing restorations too close to the heating elements or to each other will cause hot spots and uneven sintering. This can lead to distortion, an inaccurate fit, or poor aesthetics.

Making the Right Choice for Your Goal

To achieve predictable, high-quality results, you must align the furnace's capabilities and its operation with your primary objective.

- If your primary focus is aesthetic accuracy: Prioritize a furnace with excellent temperature uniformity and robust vacuum capabilities to achieve ideal translucency and vitality.

- If your primary focus is structural integrity: Meticulously follow the material-specific firing program, paying closest attention to the controlled cooling rates to prevent thermal shock.

- If your primary focus is lab efficiency: Utilize a furnace with a clear user interface and programmable cycles to minimize user error and ensure repeatable, consistent outcomes.

Mastering the principles of the porcelain furnace is essential for transforming raw materials into functional and beautiful dental art.

Summary Table:

| Aspect | Details |

|---|---|

| Core Process | Sintering: Fusing ceramic particles at high temperatures for strength and translucency |

| Temperature Range | 900-1,500°C, depending on material (e.g., feldspathic porcelain or zirconia) |

| Firing Cycle Stages | 1. Preparation and Loading 2. Ramp-Up 3. Hold/Soak 4. Controlled Cooling |

| Key Components | Muffle, Heating Elements, Temperature Controller, Vacuum Pump |

| Common Pitfalls | Material-program mismatch, thermal shock, improper loading |

| Primary Goals | Aesthetic accuracy, structural integrity, lab efficiency |

Unlock Precision in Dental Ceramics with KINTEK

Are you aiming for flawless dental restorations with superior strength and aesthetics? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs.

Let us help you achieve consistent, high-quality results—contact us today to discuss how our furnaces can enhance your lab's efficiency and outcomes!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision