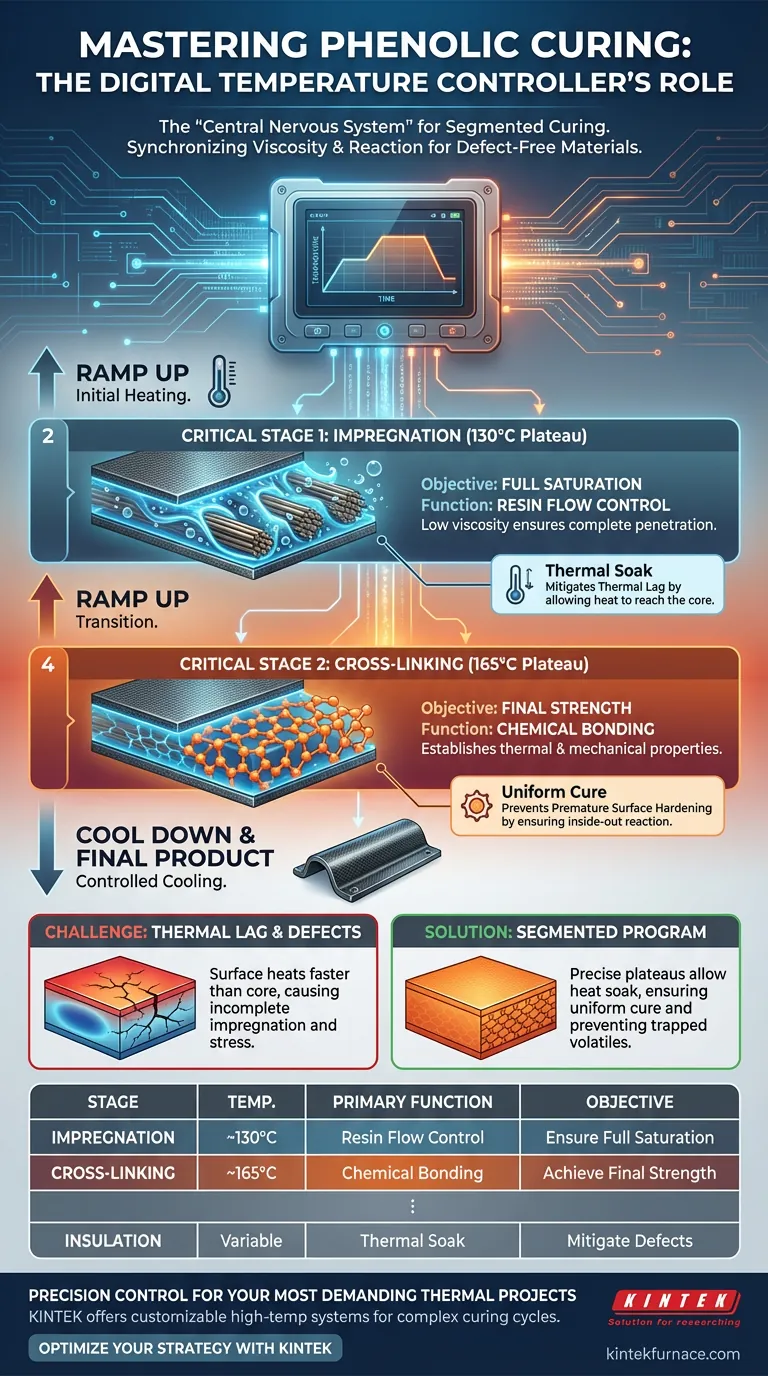

A digital temperature controller acts as the central nervous system for the segmented curing of phenolic thermal protection materials. It executes a precise, multi-stage heating and insulation program designed to synchronize the resin's physical viscosity changes with its chemical reaction rate, ensuring a defect-free final structure.

By enforcing strict temperature plateaus at critical points like 130°C and 165°C, the controller allows sufficient time for resin flow before final hardening occurs. This precise regulation prevents structural defects caused by thermal lag, such as incomplete impregnation or uneven curing.

Coordinating Viscosity and Chemical Reaction

Managing Multi-Stage Profiles

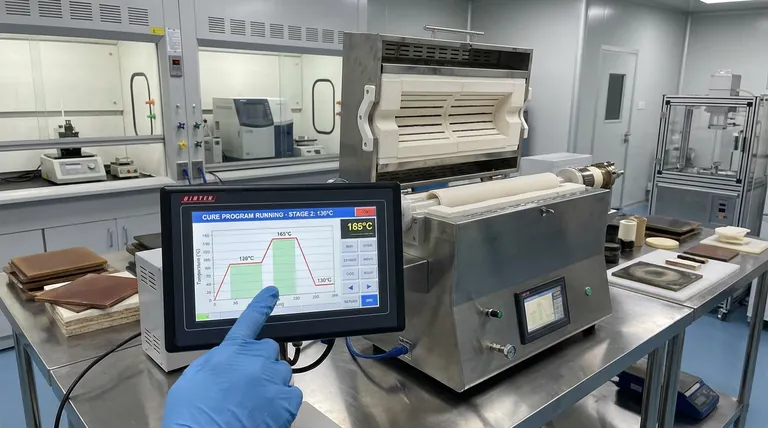

The controller does not simply maintain a single set point. Instead, it manages a dynamic multi-stage heating program.

This involves ramping temperatures up and holding them steady at specific intervals (insulation stages). This "segmented" approach is essential for complex chemical processing.

Synchronizing Flow and Cure

The primary function of the controller is to align viscosity evolution with the chemical reaction rate.

If the temperature rises too fast, the resin reacts and hardens before it can flow properly. The controller regulates the heat to keep the resin fluid long enough to penetrate the material fully.

Critical Control Stages in Phenolic Curing

The Impregnation Stage (130°C)

According to standard processing protocols, the controller must strictly regulate the temperature around 130°C.

At this stage, the priority is resin flow and impregnation. The controller maintains this plateau to ensure the resin viscosity is low enough to saturate the reinforcement materials completely.

The Cross-Linking Stage (165°C)

Once impregnation is achieved, the controller ramps the system to a higher threshold, typically around 165°C.

This stage is dedicated to thorough cross-linking. Holding this temperature ensures the chemical bonds form completely, establishing the material's final thermal and mechanical strength.

Mitigating Thermal Lag and Defects

Combating Thermal Lag

In thick or complex thermal protection materials, the core temperature often lags behind the surface temperature.

The controller mitigates this thermal lag by holding temperatures steady. This allows the heat to soak through to the center of the material before the program advances to the next stage.

Preventing Premature Surface Hardening

If the controller fails to manage these stages, the surface of the material may cure and harden while the inside is still reacting.

This premature surface hardening creates a seal that can trap volatiles or prevent internal resin flow. The controller’s segmented program ensures the material cures uniformly from the inside out.

Optimizing Your Curing Strategy

To ensure high-performance results, you must configure your controller based on the specific phase of the cure:

- If your primary focus is achieving full saturation: Ensure the controller holds the 130°C stage long enough to accommodate the resin's specific viscosity profile.

- If your primary focus is maximizing mechanical strength: Verify that the 165°C stage is maintained until thorough cross-linking is confirmed throughout the material thickness.

Precise digital control transforms a volatile chemical reaction into a predictable, high-quality manufacturing process.

Summary Table:

| Curing Stage | Temperature Plateau | Primary Function | Objective |

|---|---|---|---|

| Impregnation | ~130°C | Resin Flow Control | Ensure full saturation & low viscosity |

| Cross-Linking | ~165°C | Chemical Bonding | Achieve final thermal & mechanical strength |

| Insulation | Variable | Thermal Soak | Mitigate thermal lag & prevent internal defects |

Precision Control for Your Most Demanding Thermal Projects

Don’t let thermal lag or premature hardening compromise your materials. KINTEK provides the cutting-edge R&D and manufacturing expertise needed to master complex curing cycles.

Backed by industry-leading technology, our Muffle, Tube, Rotary, Vacuum, and CVD systems are fully customizable to meet your specific phenolic processing requirements. Whether you need to synchronize viscosity flow or ensure thorough cross-linking, KINTEK high-temp lab furnaces deliver the precise, segmented control your lab demands.

Ready to optimize your curing strategy? Contact KINTEK today for a custom solution!

Visual Guide

References

- Xiaodong He, Hualian Li. A Study on the Compaction Behavior and Parameter Sensitivity of Curing Phenolic Thermal Protection Material Strips. DOI: 10.3390/polym17081045

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does advanced power control extend heating element lifespan? Boost Efficiency and Cut Costs

- How does the resistivity of silicon carbide change with temperature? Discover SiC's Self-Regulating Heating Properties

- What are the components of a tubular heater? Discover Key Parts for Efficient Industrial Heating

- What are precious metals used as high-temperature heating elements? Essential for Extreme Heat Applications

- What are the benefits of Molybdenum Disilicide heating elements? Achieve Reliable High-Temp Performance Up to 1800°C

- What role do silicon carbide heating elements play in ceramics and glass manufacturing? Achieve Superior Heat Control and Efficiency

- Why Use Three Independent Heating Elements in Oxidation Kinetics? Achieve Precise Zonal Control for Accurate Data

- Why are electric heating elements popular in the heat-treating industry? Unlock Precision and Reliability