In short, a chiller protects a vacuum furnace by actively removing waste heat, thereby preventing the damaging effects of thermal stress on the furnace's structural components. By maintaining a stable operating temperature, the chiller directly combats the premature wear, distortion, and potential failure of critical systems, significantly extending the equipment's operational lifespan.

The chiller is not merely a cooling accessory; it is the furnace's life support system. Its primary function is to safeguard the furnace's structural integrity and vacuum seals from the immense thermal energy generated during a heating cycle.

The Core Problem: Managing Extreme Heat Transfer

A vacuum furnace operates by creating intense heat in a vacuum-sealed chamber. While this heat is essential for treating the workpiece, it becomes a significant threat to the furnace structure itself once the heating cycle is complete or during steady-state operation.

From Workpiece to Furnace Walls

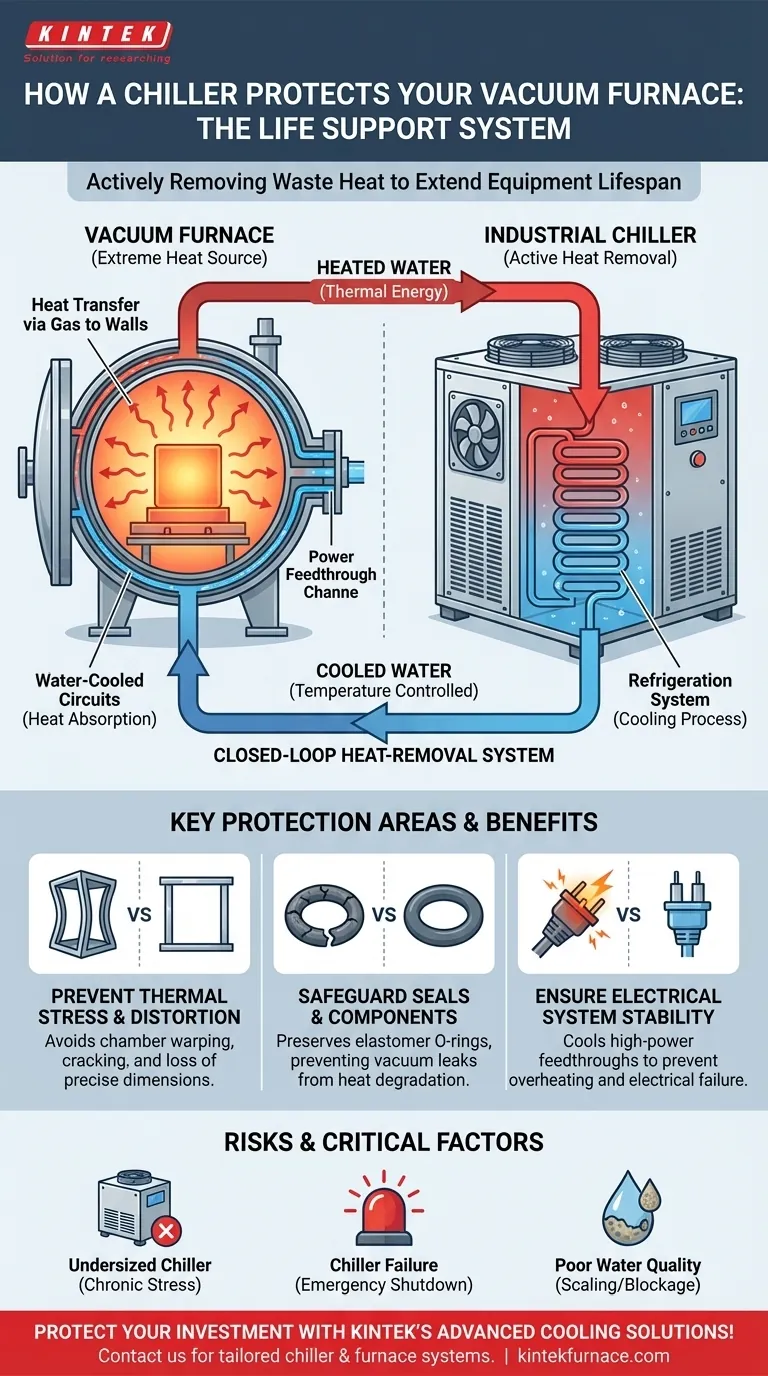

During a cooling or quenching cycle, heat is rapidly removed from the hot workpiece. This is often accomplished by backfilling the chamber with an inert gas like argon or nitrogen, which absorbs the thermal energy and transfers it to the internal walls of the vacuum chamber.

The Role of Water-Cooled Circuits

The furnace chamber, door, and other critical components like power feedthroughs are designed with internal channels or jackets. Water continuously flows through these circuits, acting as a heat transfer medium. The water absorbs the thermal energy that has been transferred to the furnace walls.

Where the Chiller Enters the System

This heated water is then pumped out of the furnace and into the industrial chiller. The chiller's refrigeration system removes the heat from the water, cooling it back down to a specified temperature before circulating it back to the furnace. This creates a continuous, closed-loop heat-removal system.

How a Chiller Provides Direct Protection

Without this active heat removal, the furnace structure would quickly overheat, leading to catastrophic failure. The chiller's protection is multifaceted and critical for reliable operation.

Preventing Thermal Stress and Distortion

The most significant threat to a vacuum furnace is thermal stress. As the massive steel chamber heats up and cools down, it expands and contracts. If this process is uncontrolled, uneven, or too extreme, it can cause the chamber to warp, crack, or lose its precise dimensions, compromising its ability to hold a vacuum. A chiller ensures the chamber's temperature remains stable and within safe design limits.

Safeguarding Seals and Components

The integrity of a vacuum furnace depends on its seals, typically made of elastomer O-rings. Excessive heat will cause these seals to degrade, harden, and fail, leading to vacuum leaks. The chiller keeps the sealing surfaces cool, preserving the life of the O-rings and ensuring a reliable vacuum.

Ensuring Electrical System Stability

High-power electrical connections, known as power feedthroughs, are another vulnerable point. These components carry immense current into the chamber and generate their own heat. These feedthroughs are water-cooled, and the chiller is responsible for preventing them from overheating, which could cause electrical failure or a loss of vacuum.

Understanding the Risks and Trade-offs

The effectiveness of the furnace's protection is directly tied to the performance and proper sizing of the chiller. Misjudging this critical component introduces significant operational risk.

The Risk of an Undersized Chiller

A chiller that is too small for the furnace's heat load cannot remove thermal energy fast enough. This will result in a gradual rise in the furnace's base temperature, leading to chronic thermal stress and a shortened equipment lifespan, even if no immediate failure occurs.

The Danger of Chiller Failure

A sudden chiller failure during or immediately after a high-temperature cycle is a critical emergency. Without cooling water flow, the furnace's structural temperature will rise rapidly, creating an immediate risk of permanent damage to the chamber, seals, and power systems. All modern furnaces have safety interlocks to trigger an emergency shutdown in this event.

The Importance of Water Quality

The water within the closed loop is a critical component. Using untreated water can lead to mineral scaling (like limescale) or biological growth inside the furnace's cooling channels. This buildup acts as an insulator, impeding heat transfer and eventually blocking flow, creating the same effect as a chiller failure.

Making the Right Choice for Your Goal

The chiller is an integral part of the vacuum furnace system. Its selection and maintenance should be treated with the same seriousness as the furnace itself.

- If your primary focus is maximizing equipment lifespan: Invest in a properly sized, high-quality chiller and strictly adhere to the manufacturer's maintenance schedule for both the chiller and the water circuit.

- If your primary focus is achieving process consistency: Monitor the chiller's performance to ensure it delivers a stable water temperature, as this directly translates to a stable and repeatable thermal environment inside your furnace.

- If your primary focus is operational reliability: Treat the chiller as a mission-critical system. Implement regular inspections and consider having critical spare parts on hand to minimize downtime in case of a fault.

Ultimately, the chiller serves as the primary guardian of your capital investment, ensuring the vacuum furnace's structural integrity and operational reliability for years to come.

Summary Table:

| Protection Aspect | Key Benefit |

|---|---|

| Thermal Stress Prevention | Avoids warping, cracking, and distortion of furnace components |

| Seal Safeguarding | Preserves O-rings and prevents vacuum leaks from heat degradation |

| Electrical System Stability | Cools power feedthroughs to prevent overheating and failures |

| Heat Removal Efficiency | Maintains stable operating temperatures for consistent performance |

Protect your vacuum furnace investment with KINTEK's advanced cooling solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, enhancing equipment lifespan and process reliability. Contact us today to discuss how our tailored chiller and furnace solutions can safeguard your operations and maximize efficiency!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- How are parts loaded into a vacuum furnace? Ensure Precision and Efficiency in Your Process

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing