At its core, a vacuum furnace enables the creation of new, high-performance materials by providing an extremely pure, high-temperature environment. By removing air and other gases, these furnaces prevent oxidation and contamination that would otherwise degrade material properties, a critical requirement for fields ranging from semiconductors to nanomaterials.

The fundamental contribution of a vacuum furnace is not just heating, but creating a chemically inert stage. This allows for the synthesis and refinement of materials whose atomic structures and performance are highly sensitive to contamination from the atmosphere.

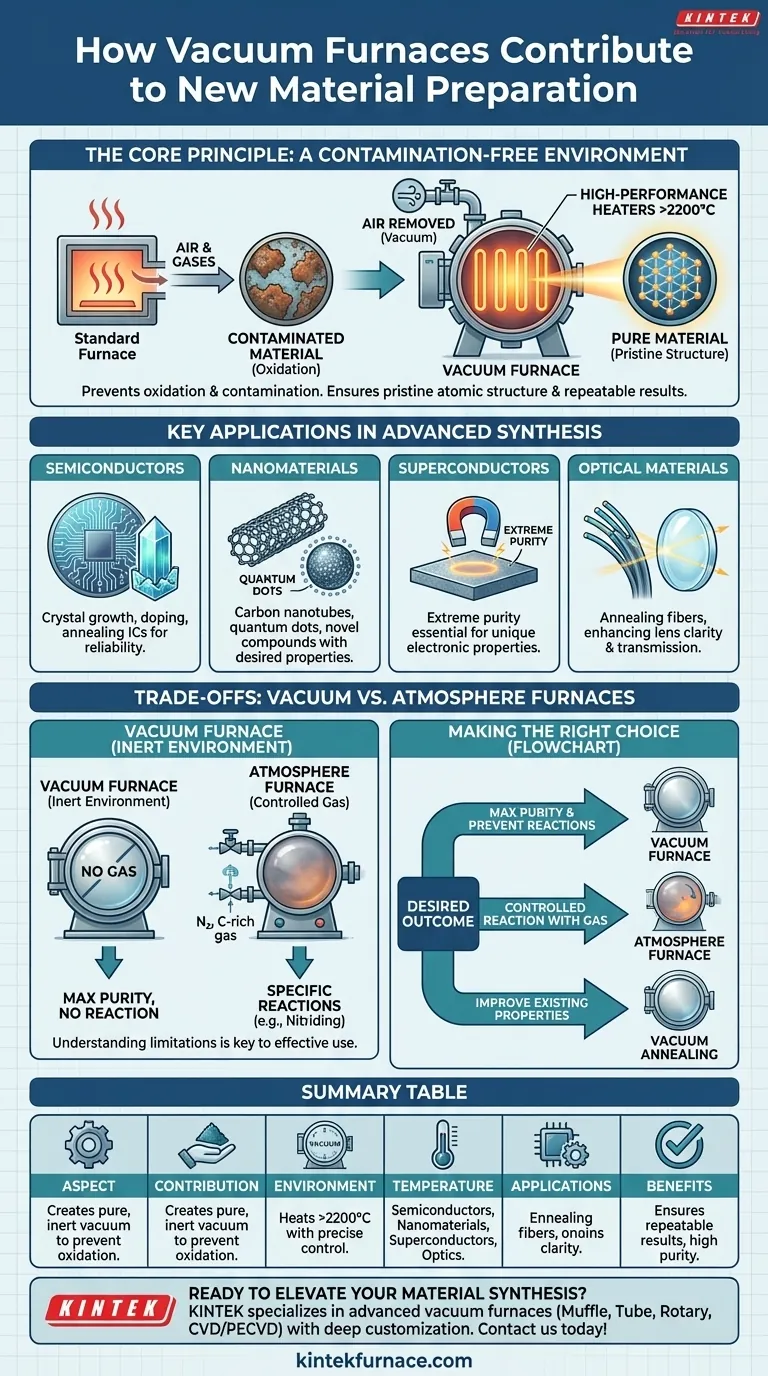

The Core Principle: A Contamination-Free Environment

To understand the furnace's role, you must first understand the problem it solves: unwanted chemical reactions. At high temperatures, most materials are highly reactive, especially with oxygen.

How a Vacuum Furnace Works

A vacuum furnace is a sealed chamber from which air and other gases are removed by a vacuum pump system. Once a vacuum is established, high-performance heating elements, often made of molybdenum or tungsten, heat the material inside to temperatures that can exceed 2200°C. The result is a clean, precisely controlled heating process, free from atmospheric interference.

Why Vacuum is Critical for Purity

The primary benefit of this process is the prevention of oxidation and other forms of contamination. Removing oxygen, nitrogen, and moisture from the chamber ensures that the material being processed does not form unintended oxides or nitrides on its surface. This level of purity is non-negotiable for materials whose performance depends on a pristine atomic structure.

Achieving Precise and Repeatable Results

By operating in a sealed, controlled environment, vacuum furnaces provide a highly repeatable process. This allows material scientists and engineers to reliably study material behavior and produce components with consistent, predictable properties, which is foundational for modern manufacturing and R&D.

Key Applications in Advanced Material Synthesis

The unique environment created by vacuum furnaces has made them indispensable for producing a wide range of advanced materials.

The Semiconductor Industry

Vacuum furnaces are essential for manufacturing integrated circuits. Processes like crystal growth, doping (introducing controlled impurities into silicon), and annealing wafers to repair crystalline damage all demand a contamination-free environment to ensure the reliability and performance of sensitive electronic components.

Nanomaterials and Novel Compounds

The synthesis of new materials like carbon nanotubes, quantum dots, and specialized oxide films relies heavily on vacuum processing. The furnace ensures that these nanostructures form with the desired properties and purity, which is critical for their application in optoelectronics and magnetic materials.

Superconducting and High-Purity Materials

Materials like superconductors are defined by their extreme purity. Even minuscule amounts of contamination can disrupt their unique electronic properties. Vacuum furnaces provide the ideal environment for forming and processing these materials to achieve the required structural and chemical integrity.

Enhancing Optical Materials

In optics, vacuum furnaces are used for annealing optical fibers to eliminate internal stresses, which directly improves their light transmission performance. Similarly, they are used to enhance the clarity and uniformity of optical lenses, a key factor in high-performance imaging systems.

Understanding the Trade-offs and Alternatives

While powerful, a vacuum furnace is not the universal solution for all high-temperature material processing. Understanding its limitations is key to using it effectively.

The Need for a Controlled Atmosphere

The primary function of a vacuum furnace is to create an inert environment. However, some material synthesis processes require a reaction with a specific gas. For example, some nitriding or carburizing processes need a controlled nitrogen or carbon-rich atmosphere.

The Role of Atmosphere Furnaces

This is where atmosphere furnaces become important. Unlike vacuum furnaces, which remove all gases, atmosphere furnaces are designed to maintain a specific, controlled gas environment. They are crucial for synthesizing materials like lithium-ion battery cathodes, which often require a high-temperature, oxygen-rich atmosphere to achieve the correct purity and crystallinity.

Making the Right Choice for Your Goal

Selecting the right thermal processing technology depends entirely on the desired outcome for your material.

- If your primary focus is maximum purity and preventing all reactions: A vacuum furnace is the definitive choice for materials sensitive to oxidation or atmospheric contamination.

- If your primary focus is a controlled reaction with a specific gas: An atmosphere furnace is necessary to introduce and maintain the required processing gas.

- If your primary focus is improving the properties of an existing material: Vacuum annealing can remove internal stresses and improve crystalline structure without altering the material's chemical composition.

Ultimately, vacuum furnace technology provides the pristine conditions necessary to push the boundaries of what is possible in materials science and engineering.

Summary Table:

| Aspect | Contribution |

|---|---|

| Environment | Creates a pure, inert vacuum to prevent oxidation and contamination |

| Temperature | Heats materials above 2200°C with precise control for synthesis |

| Applications | Essential for semiconductors, nanomaterials, superconductors, and optics |

| Benefits | Ensures repeatable results, high purity, and enhanced material properties |

Ready to elevate your material synthesis with pure, high-temperature solutions? KINTEK specializes in advanced vacuum furnaces tailored for industries like semiconductors and nanomaterials. Leveraging our exceptional R&D and in-house manufacturing, we offer a product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our furnaces can drive your innovations forward!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity