User feedback consistently highlights a highly positive experience with the dental zirconia sintering furnace's interface and controls. Technicians report that the touchscreen is intuitive and easy to navigate, which significantly reduces the need for extensive training. The simplicity of setting up sintering cycles and the ability to customize settings for different materials are frequently praised features.

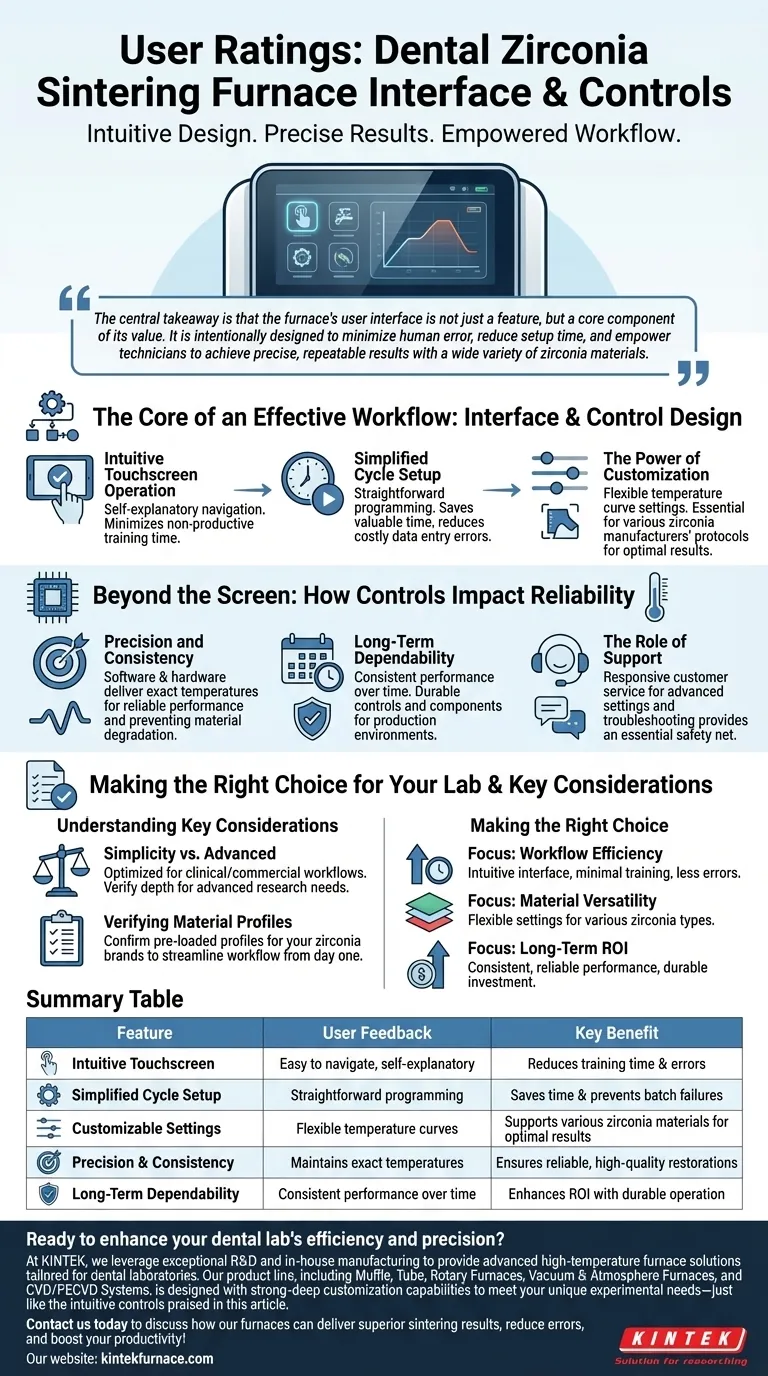

The central takeaway is that the furnace's user interface is not just a feature, but a core component of its value. It is intentionally designed to minimize human error, reduce setup time, and empower technicians to achieve precise, repeatable results with a wide variety of zirconia materials.

The Core of an Effective Workflow: Interface & Control Design

The design of a furnace's control system directly impacts a dental lab's daily efficiency, consistency, and a technician's confidence. User reports indicate this furnace excels by focusing on practical, real-world usability.

Intuitive Touchscreen Operation

Users find the touchscreen interface to be self-explanatory. This ease of use means new technicians can become proficient with the equipment in a very short time, minimizing the non-productive training period and reducing the burden on senior staff.

Simplified Cycle Setup

The process of programming a sintering cycle is described as straightforward. This simplicity is a critical factor in a busy lab environment, as it saves valuable time and, more importantly, reduces the likelihood of costly data entry errors that could ruin a batch.

The Power of Customization

The system provides flexible temperature curve settings. This is not merely a technical feature; it is a fundamental requirement for modern dental labs that use zirconia from various manufacturers, each with unique sintering protocols. This control allows the lab to perfectly match the furnace's cycle to the material's specifications, ensuring optimal translucency and strength.

Beyond the Screen: How Controls Impact Reliability

An interface is only as good as the performance it controls. The furnace's software and hardware work in concert to deliver the precision required for high-quality dental restorations.

Precision and Consistency

The ability to precisely program temperature curves translates directly into reliable performance. Users report that the furnace maintains exact temperatures throughout the sintering cycle, which is essential for preventing material degradation and achieving consistent final results.

Long-Term Dependability

Feedback indicates the furnace maintains its performance over time. One user noted their unit runs like new after more than a year of consistent use, demonstrating that the controls and internal components are built for durability in a production environment.

The Role of Support

While the interface is intuitive, users also report positive experiences with customer service. Having responsive and helpful support for questions about advanced settings or troubleshooting provides an essential safety net, further enhancing the overall user experience.

Understanding the Key Considerations

While feedback is overwhelmingly positive, a strategic evaluation involves understanding the context of that feedback. The furnace's design philosophy prioritizes simplicity and reliability for the most common dental lab workflows.

Simplicity vs. Advanced Experimentation

The furnace is optimized for efficiency and ease of use in a clinical or commercial lab setting. Labs focused on materials research or developing highly experimental protocols should verify that the programming depth meets their specific, non-standard requirements.

Verifying Material Profiles

Before purchase, it is wise to confirm if the furnace comes pre-loaded with profiles for the specific zirconia brands your lab currently uses. While custom curves are easy to program, pre-loaded settings can further streamline workflow from day one.

Making the Right Choice for Your Lab

The right equipment aligns with your lab's specific operational goals. The user feedback on this furnace's controls points to clear strengths for distinct priorities.

- If your primary focus is workflow efficiency: The intuitive interface and minimal training time will directly contribute to a more productive and less error-prone team.

- If your primary focus is material versatility: The flexible, customizable temperature curve settings are critical for achieving manufacturer-specified results across a wide range of zirconia types.

- If your primary focus is long-term ROI: User reports on consistent, reliable performance suggest the furnace is a durable investment that delivers predictable outcomes day after day.

Ultimately, the furnace's controls are designed to empower the technician, ensuring the final output is a result of their skill, not a struggle with the equipment.

Summary Table:

| Feature | User Feedback | Key Benefit |

|---|---|---|

| Intuitive Touchscreen | Easy to navigate, self-explanatory | Reduces training time and errors |

| Simplified Cycle Setup | Straightforward programming | Saves time and prevents batch failures |

| Customizable Settings | Flexible temperature curves | Supports various zirconia materials for optimal results |

| Precision and Consistency | Maintains exact temperatures | Ensures reliable, high-quality restorations |

| Long-Term Dependability | Consistent performance over time | Enhances ROI with durable operation |

Ready to enhance your dental lab's efficiency and precision?

At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed with strong deep customization capabilities to meet your unique experimental needs—just like the intuitive controls praised in this article.

Contact us today to discuss how our furnaces can deliver superior sintering results, reduce errors, and boost your productivity!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What is sintering in dental? The Key to Durable, High-Strength Zirconia Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations