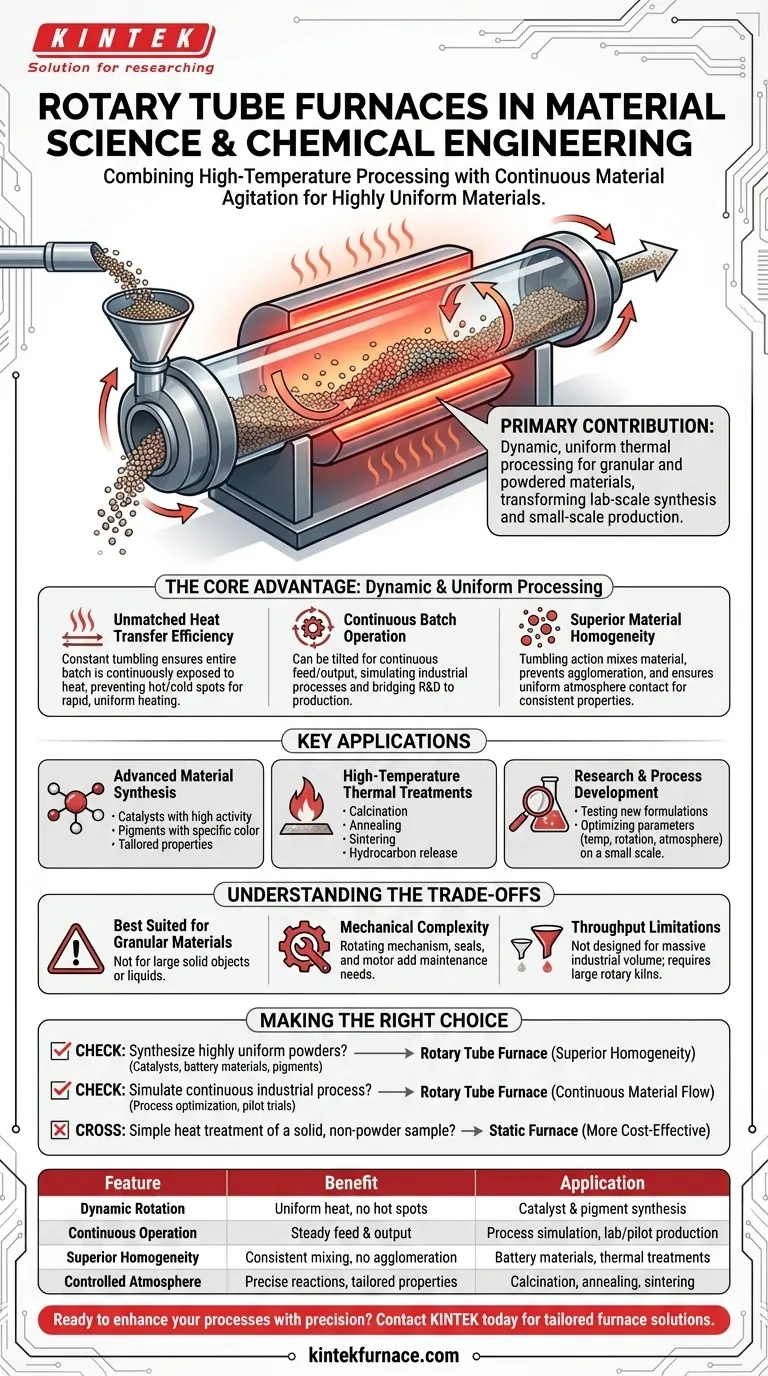

At their core, rotary tube furnaces are pivotal instruments in material science and chemical engineering because they uniquely combine high-temperature processing with continuous material agitation. This allows for the creation of highly uniform, homogenous materials by ensuring every particle is treated equally, a feat difficult to achieve in static furnace designs. Their capabilities are essential for developing advanced catalysts, pigments, and other specialized powders with precisely tailored properties.

The primary contribution of a rotary tube furnace is its ability to provide dynamic, uniform thermal processing for granular and powdered materials. This transforms lab-scale synthesis and small-scale production by enabling unparalleled process control, heat transfer efficiency, and material homogeneity.

The Core Advantage: Dynamic and Uniform Processing

The defining feature of a rotary tube furnace is its rotating process tube. This simple mechanical action provides three fundamental advantages over static furnaces.

Unmatched Heat Transfer Efficiency

The constant tumbling motion ensures that the entire material batch is continuously exposed to the furnace's heat source. This prevents hot spots and cold spots within the material bed.

This dynamic exposure leads to exceptionally rapid and uniform heating, shortening processing times and reducing energy consumption.

Continuous Batch Operation

Unlike a static furnace that processes one fixed batch at a time, a rotary furnace can be tilted to allow for a continuous feed of raw material and a steady output of finished product.

This capability is invaluable for simulating industrial-scale processes in a lab environment and for small-scale production runs, bridging the gap between initial research and commercial manufacturing.

Superior Material Homogeneity

For powder processing, the tumbling action is critical. It consistently mixes the material, preventing particles from sticking together (agglomeration) and ensuring that any atmospheric gases used in the process reach the entire batch.

This results in a final product with exceptional chemical and physical uniformity, which is crucial for applications like high-performance catalysts or consistent color pigments.

Key Applications in Material Science and Engineering

The unique processing environment of a rotary tube furnace makes it indispensable for several critical applications.

Advanced Material Synthesis

These furnaces are used to produce materials where precise control over the final properties is paramount. This includes creating catalysts with high activity and selectivity or pigments with specific color saturation and durability.

The combination of a controlled atmosphere and uniform high temperature allows engineers to precisely dictate the outcome of chemical reactions during synthesis.

High-Temperature Thermal Treatments

Rotary furnaces are ideal for a range of thermal treatments. Processes like calcination (heating solids to high temperatures), annealing (heating and slow cooling to reduce hardness), and sintering (fusing powders together) benefit from the uniform heat.

A practical example is the heating of oil shale to release hydrocarbons, a process that requires efficient and consistent heat transfer through a granular material.

Research and Process Development

For universities, research institutes, and corporate R&D labs, the rotary tube furnace is a versatile tool for experimentation.

It allows researchers to test new material formulations and optimize processing parameters (like temperature, rotation speed, and atmosphere) on a small, manageable scale before committing to large-scale production.

Understanding the Trade-offs

While powerful, rotary tube furnaces are specialized tools. Understanding their limitations is key to using them effectively.

Best Suited for Granular Materials

The design's primary strength is processing powders, granules, and other small particulates. It is not suitable for treating large, monolithic solid objects or processing liquids.

Mechanical Complexity

The rotating mechanism, including the motor and gas-tight seals, adds a layer of mechanical complexity compared to a static furnace. This can result in higher initial costs and more demanding maintenance requirements to ensure reliable, atmosphere-controlled operation.

Throughput Limitations

While they enable continuous processing, lab- and pilot-scale rotary tube furnaces are not designed for massive industrial throughput. Very large volume production typically requires a move to much larger, dedicated equipment like an industrial rotary kiln.

Making the Right Choice for Your Process

Selecting the right furnace depends entirely on the material you are processing and your end goal.

- If your primary focus is synthesizing highly uniform powders (e.g., catalysts, battery materials, pigments): A rotary tube furnace is the superior choice, as its continuous mixing provides unmatched homogeneity.

- If your primary focus is simulating a continuous industrial process in the lab: The ability of a tilted rotary furnace to handle a constant material flow makes it an ideal tool for process optimization and pilot-scale trials.

- If your primary focus is the simple heat treatment of a solid, non-powder sample: A less complex and more cost-effective static furnace (either horizontal or vertical) is likely the more appropriate instrument.

By leveraging the unique strengths of dynamic heating and mixing, the rotary tube furnace empowers engineers and scientists to innovate with a level of precision that drives progress.

Summary Table:

| Feature | Benefit | Application |

|---|---|---|

| Dynamic Rotation | Ensures uniform heat distribution and prevents hot spots | Catalyst and pigment synthesis |

| Continuous Operation | Allows steady feed and output for process simulation | Lab-scale to pilot-scale production |

| Superior Homogeneity | Mixes materials to avoid agglomeration and ensure consistency | Battery materials and thermal treatments |

| Controlled Atmosphere | Enables precise chemical reactions and property tailoring | Calcination, annealing, sintering |

Ready to enhance your material science and chemical engineering processes with precision? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're developing catalysts, pigments, or other specialized powders, our rotary tube furnaces deliver unmatched uniformity and efficiency. Contact us today to discuss how we can tailor a solution for your specific needs!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

People Also Ask

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- How do rotary tube furnaces support real-time monitoring and continuous processing? Boost Efficiency with Continuous Flow & Live Observation

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are some applications of rotary tube furnaces? Ideal for Continuous High-Temperature Material Processing