In essence, rotary kilns improve waste heat utilization by using their hot exhaust gases to preheat the raw material before it enters the main burning zone. Specific design features, such as an expanded "cold end," are engineered to maximize the contact time between the hot gas and cool material, ensuring as much thermal energy as possible is recycled back into the process instead of being lost to the atmosphere.

The core strategy is transforming a liability—hot waste gas—into an asset. By designing the kiln for efficient counter-current heat exchange, the energy required to bring material to its reaction temperature is significantly reduced, directly lowering fuel consumption and operational costs.

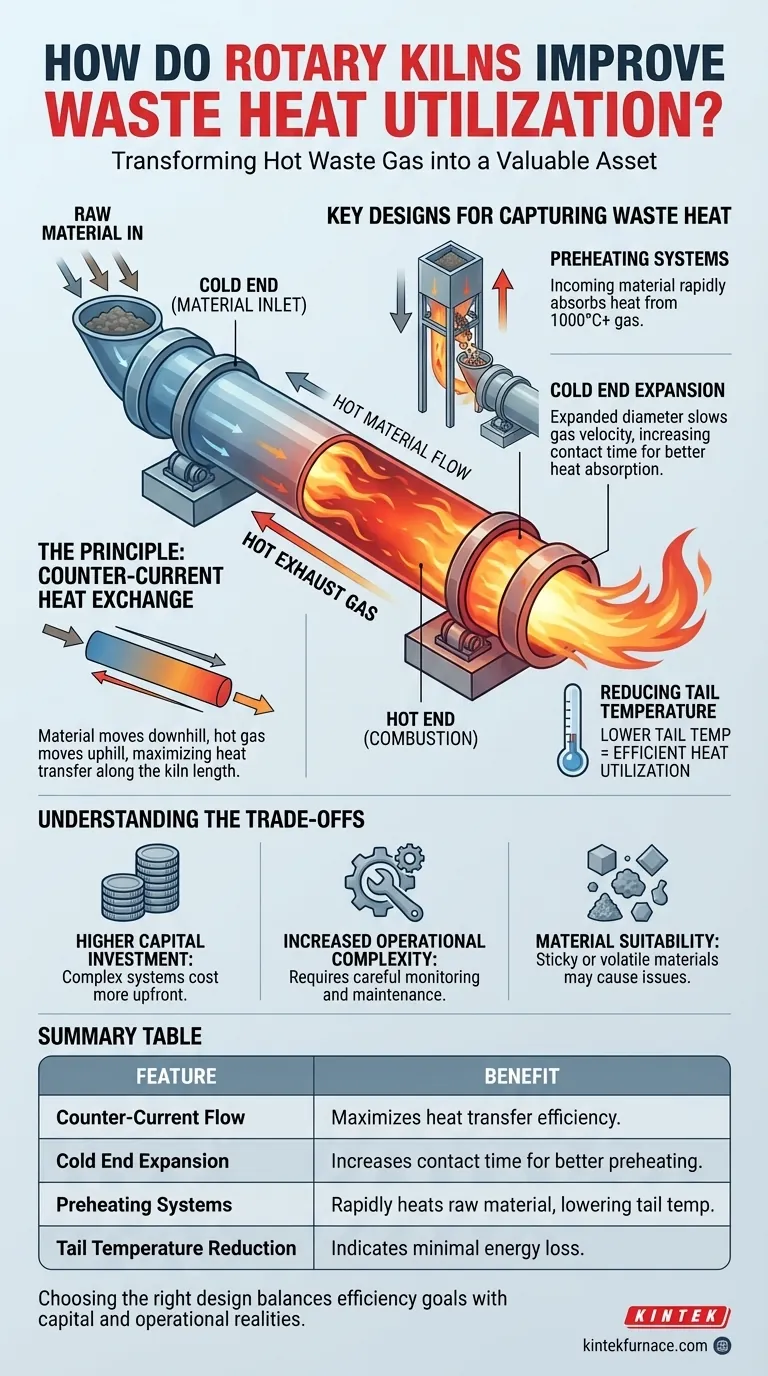

The Principle: Counter-Current Heat Exchange

What It Is

The fundamental mechanism for waste heat recovery in a rotary kiln is counter-current flow. The solid material is fed into the upper, or "cold," end of the inclined, rotating kiln and moves slowly downhill.

Simultaneously, hot gas from the fuel combustion at the lower, or "hot," end is forced to travel uphill, against the flow of the material.

Why It's Efficient

This opposite-flow arrangement creates a continuous temperature gradient. The hottest gases encounter the hottest material, while the cooler gases encounter the incoming cool material, ensuring the maximum possible heat transfer occurs along the entire length of the system.

Key Designs for Capturing Waste Heat

Preheating Systems

Modern kilns are rarely just a simple rotating tube. They are often integrated with a preheater tower or a long preheating section at the material feed end.

The hot exhaust gas, which can be over 1000°C, is ducted through this section. The incoming raw material cascades down through the hot gas stream, rapidly absorbing heat.

The "Cold End Expansion" Design

As mentioned in your inquiry, some kilns feature a cold end expansion. The diameter of the kiln at the material inlet end is intentionally made larger.

This expansion slows down the velocity of the exhaust gas and increases the cross-sectional area. Both effects give the raw material more time to absorb heat from the gas, boosting the efficiency of the preheating stage.

Reducing Tail Temperature

The ultimate measure of success is the tail temperature—the temperature of the gas as it finally exits the system. A lower tail temperature is direct proof that heat has been successfully transferred to the material rather than being wasted.

Understanding the Trade-offs

Higher Capital Investment

Systems with advanced preheaters and expanded kiln sections are more complex and expensive to construct. The initial capital outlay is significantly higher than for a simple, less efficient kiln.

Increased Operational Complexity

These systems introduce more variables to control. Preheater towers can experience blockages or "buildup" if not operated correctly, requiring careful monitoring and maintenance procedures.

Material Suitability

The effectiveness of a preheater can depend on the characteristics of the raw material. Materials that are sticky or contain high levels of volatiles may not be suitable for certain complex preheater designs, as they can cause operational problems.

Making the Right Choice for Your Goal

Selecting a kiln design requires balancing efficiency goals with capital and operational realities.

- If your primary focus is maximum energy efficiency and lowest fuel cost: Invest in a system with a multi-stage cyclone preheater and consider a design with an expanded cold end to maximize pre-calcination and heat recovery.

- If your primary focus is lower initial capital cost or processing difficult materials: A shorter, simpler kiln without an elaborate preheater might be necessary, but you must accept the trade-off of significantly higher long-term fuel consumption.

- If your primary focus is overall plant energy independence: Combine a high-efficiency kiln with a downstream Waste Heat Recovery (WHR) boiler to capture remaining exhaust heat and generate electricity.

Choosing the right design is about deliberately trading capital investment for long-term operational savings.

Summary Table:

| Feature | Benefit |

|---|---|

| Counter-Current Flow | Maximizes heat transfer by moving hot gas against cool material flow |

| Cold End Expansion | Increases contact time for better preheating and energy recovery |

| Preheating Systems | Rapidly heats raw material using exhaust gases, lowering tail temperature |

| Tail Temperature Reduction | Indicates efficient heat utilization, minimizing energy loss |

Ready to optimize your waste heat utilization with advanced rotary kilns? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Rotary Furnaces, Muffle Furnaces, Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our solutions can enhance your efficiency and reduce costs!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What is the retention time of a rotary kiln? Optimize Your Process Efficiency

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency