At their core, rotary kilns achieve exceptional safety and reliability through an integrated design philosophy that combines robust physical construction, advanced mechanical components, and intelligent process control. Key features like high-quality steel fabrication, automatic welding, hydraulic pushing mechanisms, and sophisticated sealing devices work in concert to ensure stable, long-term operation while minimizing risks to personnel and production.

The safety and reliability of a rotary kiln are not the result of a single feature, but an engineered outcome of its entire system. From the material science of its shell to the real-time data from its control systems, every component is designed to ensure containment, consistency, and durability.

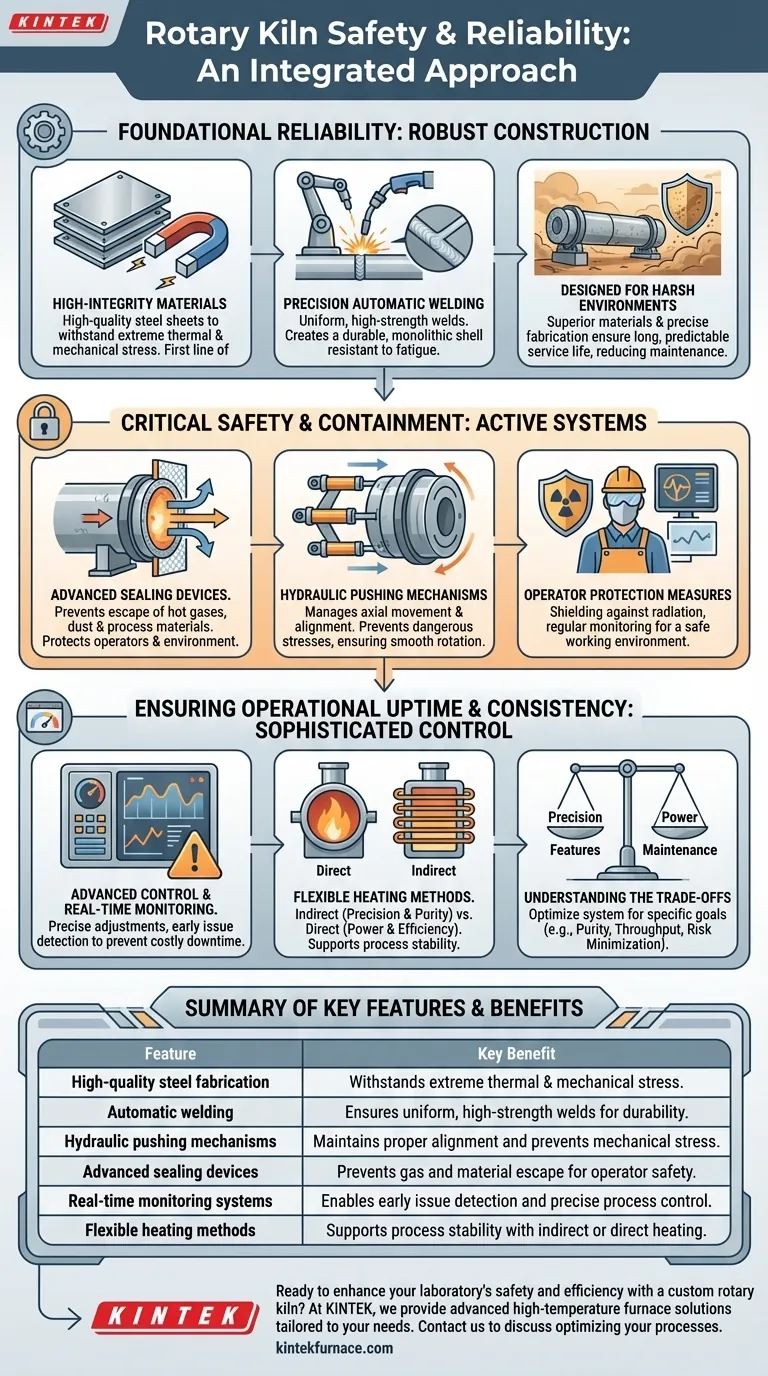

Foundational Reliability: Robust Physical Construction

The long-term performance of a rotary kiln begins with its fundamental structure. This is the bedrock upon which all other safety and reliability features are built.

High-Integrity Materials

Rotary kilns are constructed from high-quality steel sheets chosen specifically for their ability to withstand extreme thermal and mechanical stress. This material choice is the first line of defense against structural failure.

Precision Welding Techniques

These steel sheets are joined using automatic welding processes. This ensures uniform, high-strength welds across the entire structure, creating a monolithic shell that is far more durable and resistant to fatigue than manual methods would allow.

Designed for Harsh Environments

This combination of superior materials and precise fabrication results in a kiln capable of withstanding harsh industrial environments. This inherent toughness reduces the need for frequent maintenance and ensures a long, predictable service life.

Critical Safety and Containment Systems

While robust construction provides passive reliability, active systems are required to manage the dynamic process and ensure operator safety.

Advanced Sealing Devices

Perhaps one of the most critical safety components, advanced sealing devices are installed at both ends of the kiln. Their primary function is to prevent the escape of hot gases, dust, or process materials into the surrounding environment, directly protecting operators and preventing equipment contamination.

The Role of Hydraulic Pushers

Hydraulic pushing mechanisms are employed to manage the axial movement and positioning of the kiln. This controlled force ensures the kiln remains properly aligned on its supports, preventing dangerous mechanical stresses and ensuring smooth, reliable rotation.

Operator Protection Measures

In applications involving specific process energies, additional measures are taken to ensure operator safety. This can include shielding against electromagnetic radiation and regular monitoring to guarantee a safe working environment.

Ensuring Operational Uptime and Consistency

Reliability is not just about avoiding catastrophic failure; it's about delivering consistent, predictable performance day after day. Modern kilns achieve this through sophisticated oversight and control.

Advanced Control and Real-Time Monitoring

Modern rotary kilns are equipped with advanced control systems that provide real-time monitoring of all critical parameters. This allows for precise process adjustments and, crucially, enables the early detection of potential issues before they can lead to costly downtime or safety incidents.

Flexible Heating Methods for Process Stability

The method of heating is critical to process stability. Kilns can be heated indirectly (using electric heaters outside the shell) or directly (with a burner inside the shell). The choice depends on the application, with electric heat offering easier temperature control and direct combustion providing high thermal output.

Understanding the Trade-offs

Selecting a rotary kiln requires understanding the inherent trade-offs in its design. These are not flaws, but rather engineering decisions that optimize the system for specific goals.

Heating Method: Precision vs. Power

Indirect electric heating offers superior temperature control and a cleaner process environment, as the material never contacts combustion byproducts. However, it can be less energy-efficient for very high-temperature applications. Direct-fired gas heating is powerful and efficient but offers less precise control and may introduce contaminants from the flame.

System Complexity: Advanced Features vs. Maintenance

The inclusion of hydraulic systems and advanced controls dramatically enhances safety and operational consistency. The trade-off is increased system complexity. While these components are designed for reliability, they require specialized knowledge for maintenance and troubleshooting compared to a simpler mechanical system.

Making the Right Choice for Your Application

Your specific process goals should dictate the configuration of your rotary kiln system.

- If your primary focus is process purity and precise temperature control: An indirectly heated kiln with an advanced, real-time control system is the optimal choice.

- If your primary focus is high throughput for robust materials: A direct-fired kiln may provide a more powerful and cost-effective thermal solution.

- If your primary focus is minimizing operational risk and downtime: Prioritize investment in high-end sealing devices, hydraulic positioning systems, and comprehensive monitoring.

By understanding how these integrated systems contribute to performance, you can confidently specify a rotary kiln that meets the highest standards of safety and long-term reliability.

Summary Table:

| Feature | Key Benefit |

|---|---|

| High-quality steel fabrication | Withstands extreme thermal and mechanical stress |

| Automatic welding | Ensures uniform, high-strength welds for durability |

| Hydraulic pushing mechanisms | Maintains proper alignment and prevents mechanical stress |

| Advanced sealing devices | Prevents gas and material escape for operator safety |

| Real-time monitoring systems | Enables early issue detection and precise process control |

| Flexible heating methods | Supports process stability with indirect or direct heating |

Ready to enhance your laboratory's safety and efficiency with a custom rotary kiln? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Rotary Furnaces, Muffle, Tube, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is tailored to meet your unique experimental needs with deep customization capabilities. Contact us today to discuss how our reliable and safe rotary kilns can optimize your processes and deliver long-term value!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- How is bed depth controlled in a rotary kiln and why is it important? Optimize Heat Transfer and Efficiency

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency