In a PECVD system, increasing the flow rate of a reactant gas directly increases the deposition rate, but only up to a certain point. A higher flow rate supplies more of the necessary chemical precursors to the substrate surface, which can accelerate film growth. This relationship is not infinite, however, and is fundamentally limited by other process parameters like RF power and chamber pressure.

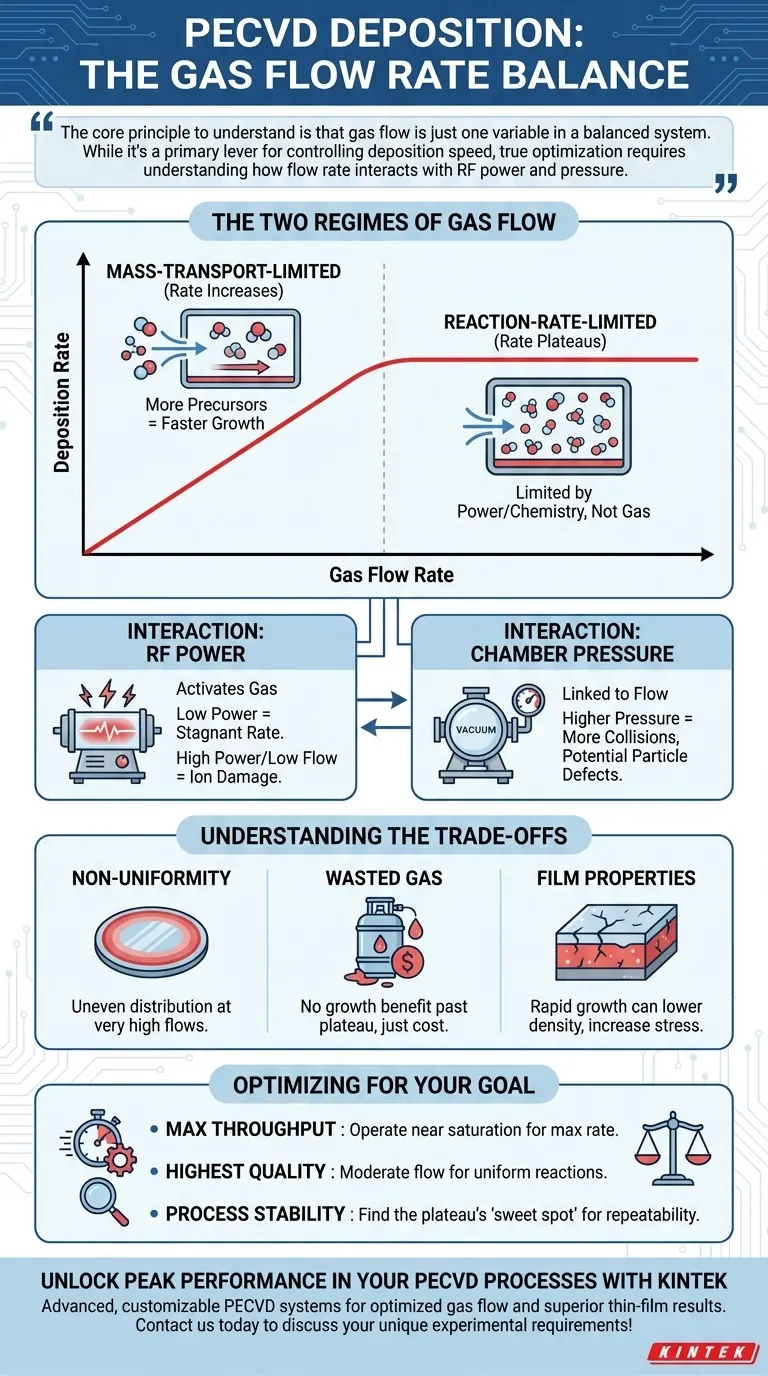

The core principle to understand is that gas flow is just one variable in a balanced system. While it's a primary lever for controlling deposition speed, true optimization requires understanding how flow rate interacts with RF power and pressure to achieve the desired balance between deposition rate and film quality.

The Role of Gas Flow in the Deposition Process

To control gas flow effectively, you must first understand its function within the PECVD chamber. The process is a dynamic balance between supplying reactants and converting them into a solid film.

Supplying the Chemical Precursors

Process gases are the raw materials for the thin film. In PECVD, these gases are introduced into a vacuum chamber where they are energized into a plasma state.

The gas flow rate determines the rate of replenishment for the reactant molecules being consumed at the substrate surface.

The Mass-Transport-Limited Regime

When the deposition rate is directly proportional to the gas flow rate, the process is considered to be in a mass-transport-limited regime.

In this state, the reaction is "starved" for reactants. The speed of the process is bottlenecked by how quickly you can supply new gas molecules to the surface. Increasing the flow rate provides more material and directly increases the deposition rate.

The Reaction-Rate-Limited Regime

Eventually, increasing the gas flow rate yields diminishing returns, and the deposition rate will plateau. This indicates the process has entered a reaction-rate-limited regime.

At this point, the bottleneck is no longer the supply of gas. Instead, it might be the amount of RF power available to ionize the gas or the speed at which chemical reactions can occur on the heated substrate. Supplying more gas will not speed up the deposition because the system cannot process the reactants any faster.

How Other Parameters Interact with Gas Flow

Gas flow does not operate in isolation. Its effect is deeply intertwined with the other primary control parameters of a PECVD system. Understanding these interactions is the key to process control.

The Role of RF Power

RF power is what generates the plasma and creates the highly reactive free radicals needed for deposition.

If RF power is low, there isn't enough energy to break down the incoming gas molecules efficiently. You can increase the gas flow all you want, but without sufficient power to "activate" it, the deposition rate will stagnate.

Conversely, if the gas flow is too low for a given power setting, the reaction will be limited by the lack of material, and the high energy could lead to undesirable ion bombardment on the substrate.

The Influence of Chamber Pressure

Chamber pressure and gas flow are related. While you can control them separately with a throttle valve and a mass flow controller, a higher gas flow rate will naturally tend to raise the chamber pressure if the pumping speed is constant.

Pressure, in turn, affects the plasma's characteristics. Higher pressure can lead to more collisions in the gas phase, which can sometimes reduce film quality by creating particles (dust) before the reactants ever reach the substrate.

Understanding the Trade-offs: Rate vs. Quality

Aggressively increasing gas flow to maximize deposition rate often comes at a cost. A trusted advisor's goal is not just to make a process faster, but to make it better and more reliable.

The Risk of Non-Uniformity

At very high flow rates, the gas may not have enough time to distribute evenly throughout the reaction chamber. This can cause the film to deposit thicker near the gas inlet and thinner further away, leading to poor uniformity across the wafer.

The Danger of Wasted Gas

Once the deposition rate has plateaued (entering the reaction-rate-limited regime), any additional increase in gas flow does not contribute to film growth. It simply means more unreacted gas is being pumped out of the chamber, which is inefficient and costly.

The Impact on Film Properties

Pushing for the absolute maximum deposition rate can compromise the quality of the film itself. Rapidly deposited films can sometimes have lower density, higher internal stress, or incorporate more impurities, all of which can degrade the performance of the final device.

Optimizing Gas Flow for Your Goal

Choosing the right gas flow rate is not about finding a single "best" value, but about balancing competing priorities for your specific application.

- If your primary focus is maximizing throughput: Operate in the mass-transport-limited regime where rate scales with flow, but stay just below the saturation point to avoid wasting gas and compromising uniformity.

- If your primary focus is achieving the highest film quality: You may need a more moderate flow rate to ensure uniform gas distribution and allow sufficient time for ideal surface reactions, even if it slightly reduces the deposition rate.

- If your primary focus is process stability: Find a "sweet spot" on the plateau of the deposition curve, where the rate is less sensitive to minor fluctuations in flow, power, or pressure, ensuring high repeatability.

Ultimately, mastering gas flow is about understanding it as one critical component in a balanced system to achieve consistent, high-quality results.

Summary Table:

| Aspect | Effect of Increasing Gas Flow Rate |

|---|---|

| Deposition Rate | Increases up to a plateau in mass-transport-limited regime |

| Film Uniformity | May decrease due to uneven gas distribution |

| Process Efficiency | Can lead to wasted gas in reaction-rate-limited regime |

| Film Quality | May degrade with higher stress or impurities |

Unlock Peak Performance in Your PECVD Processes with KINTEK

Struggling to balance deposition rate and film quality in your lab? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, helping you optimize gas flow and other parameters for consistent, high-quality results.

Contact us today to discuss how our tailored solutions can enhance your laboratory's efficiency and achieve superior thin-film deposition!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- How does PECVD contribute to semiconductor manufacturing? Enable Low-Temperature, High-Quality Film Deposition

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- What is plasma-deposited silicon nitride, and what are its properties? Discover Its Role in Solar Cell Efficiency

- What are the drawbacks of CVD compared to PECVD? Key Limitations for Your Lab