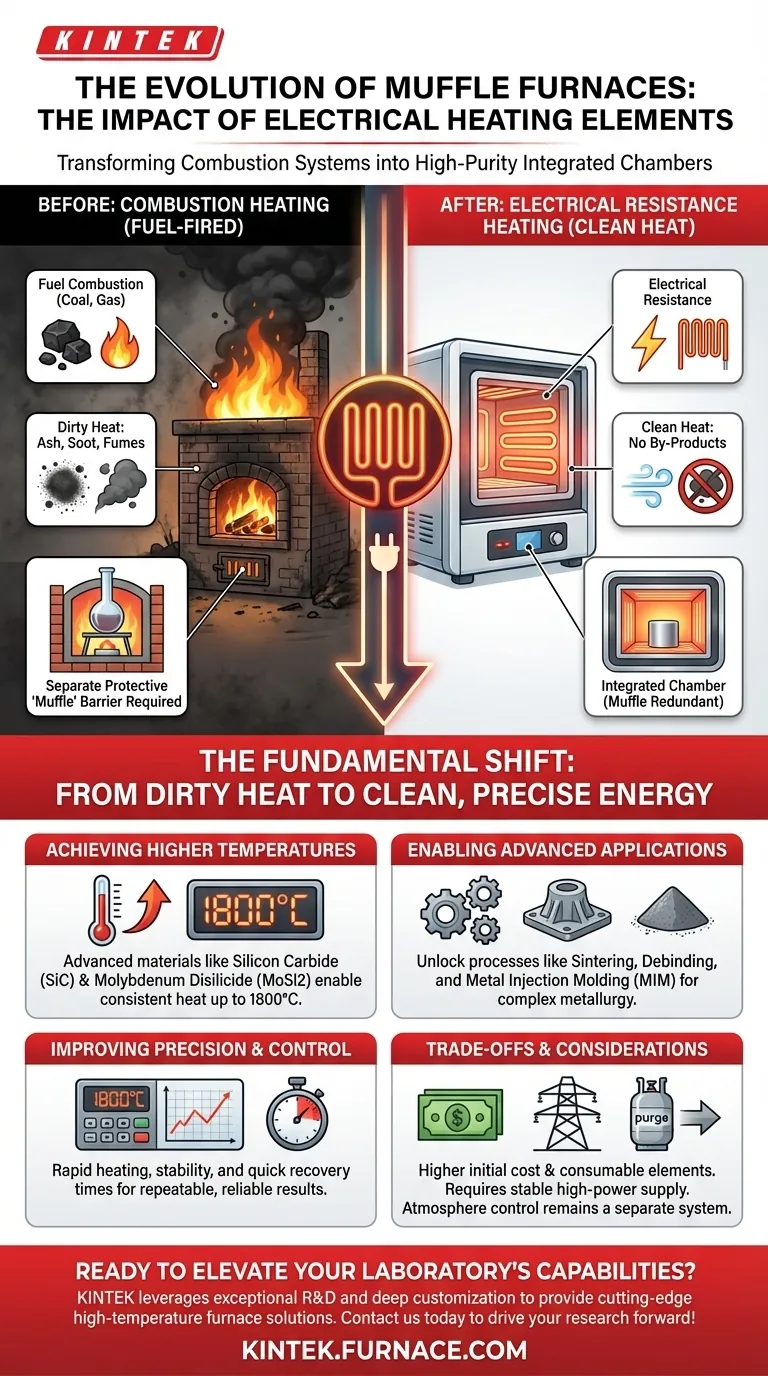

The introduction of electrical heating elements was the single most important evolution for muffle furnaces, transforming them from separated, multi-part systems into the integrated, high-purity chambers we use today. By replacing fuel combustion with clean electrical resistance, these elements eliminated by-products like ash, soot, and fumes. This fundamental change made the protective "muffle" barrier redundant, paving the way for higher performance and new industrial applications.

The shift to electrical heating wasn't just a change in power source; it redefined the furnace's core function. It made the heat source inherently clean, which eliminated the need for a separate protective muffle and unlocked the higher, more precise temperatures required for modern material science.

The Fundamental Shift: From Combustion to Clean Heat

The original muffle furnace was a solution to a problem: how to heat a material without contaminating it with the by-products of a fire. The introduction of electricity removed the problem at its source.

The Original Purpose of the Muffle

In traditional furnaces, heat was generated by burning fuel like coal or gas. This process created soot, ash, and chemical fumes that would contaminate or damage the workpiece being heated.

The muffle was a separate, sealed container (a retort) placed inside the larger furnace. It acted as a physical barrier, protecting the workload from the "dirty" heat of combustion.

The Impact of Electrical Elements

Electrical heating elements work on the principle of resistance heating. When current flows through a material like a high-temperature wire or rod, it generates intense heat without any combustion.

This process is inherently clean. There are no fumes, no ash, and no soot. The energy is delivered directly as thermal radiation or convection.

Redefining the 'Muffle' and 'Chamber'

Because the heat source was now clean, the need for a separate protective barrier vanished. The insulated heating chamber itself could now serve as the clean environment for the workload.

This is why today, the terms 'muffle furnace' and 'chamber furnace' are functionally interchangeable. The name "muffle" persists as a legacy term, but it now refers to the entire integrated heating chamber.

Unlocking New Capabilities with Advanced Materials

Eliminating contamination was only the first step. Electrical elements also allowed for the use of advanced materials that pushed the performance boundaries of what furnaces could achieve.

Achieving Higher and More Precise Temperatures

Modern electrical furnaces use specialized heating elements made from materials like silicon carbide or molybdenum disilicide.

These advanced elements can safely and consistently reach working temperatures up to 1,800°C (3,272°F). This is a level of heat that is difficult to achieve and control with traditional fuel combustion.

Enabling Sophisticated Industrial Processes

The combination of a pure heating environment and ultra-high temperatures unlocked new applications, particularly in metallurgy and advanced manufacturing.

These capabilities are critical for processes like sintering (fusing powdered material), debinding (removing binders from molded parts), and creating complex parts through metal injection molding (MIM).

Improving Efficiency and Control

Electrical heat provides far more precise control than regulating a flame. Modern furnaces offer rapid heating, temperature stability, and quick recovery times in self-contained, energy-efficient cabinets. This leads to more repeatable and reliable results.

Understanding the Trade-offs

While electrically heated furnaces represent a major technological leap, it's important to recognize the context of their use.

Initial Cost and Consumables

High-performance electric furnaces, especially those using advanced molybdenum disilicide elements, can have a significant upfront cost compared to simpler fuel-fired designs. The heating elements themselves are also consumables that will eventually require expensive replacement.

Reliance on Electrical Infrastructure

These furnaces require a stable and often high-power electrical supply. In locations where electricity is expensive or the grid is unreliable, a gas-fired furnace may still be a more practical alternative for certain applications.

Atmosphere Control Is a Separate Concern

While the heat source is clean, the air inside the chamber is not inert. For processes that require a specific atmosphere (e.g., nitrogen or argon to prevent oxidation), an electric furnace still needs an independent system to purge the air and supply the controlled gas.

Making the Right Choice for Your Goal

Understanding the evolution from combustion to electricity helps clarify which technology is appropriate for a specific task.

- If your primary focus is process purity and precision: An electric muffle furnace is the definitive choice, as it eliminates combustion contaminants at the source.

- If you need to reach very high temperatures for advanced materials: A modern electric furnace with specialized silicon carbide or molybdenum disilicide elements is essential.

- If your main constraints are initial cost and utility availability: A traditional fuel-fired furnace can still be viable, but you must plan for how to manage workpiece contamination.

Ultimately, knowing how your furnace generates heat is the key to mastering its capabilities and achieving reliable results.

Summary Table:

| Aspect | Before Electrical Elements | After Electrical Elements |

|---|---|---|

| Heat Source | Fuel combustion (e.g., coal, gas) | Electrical resistance heating |

| Contamination | High (soot, ash, fumes) | Eliminated (clean heat) |

| Temperature Range | Limited, less precise | Up to 1,800°C, highly precise |

| Applications | Basic heating, limited by contamination | Sintering, debinding, MIM, advanced metallurgy |

| Efficiency & Control | Lower, harder to regulate | High precision, rapid heating, stability |

Ready to elevate your laboratory's capabilities with advanced high-temperature furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse labs with cutting-edge products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our solutions can drive your research and industrial processes forward!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity