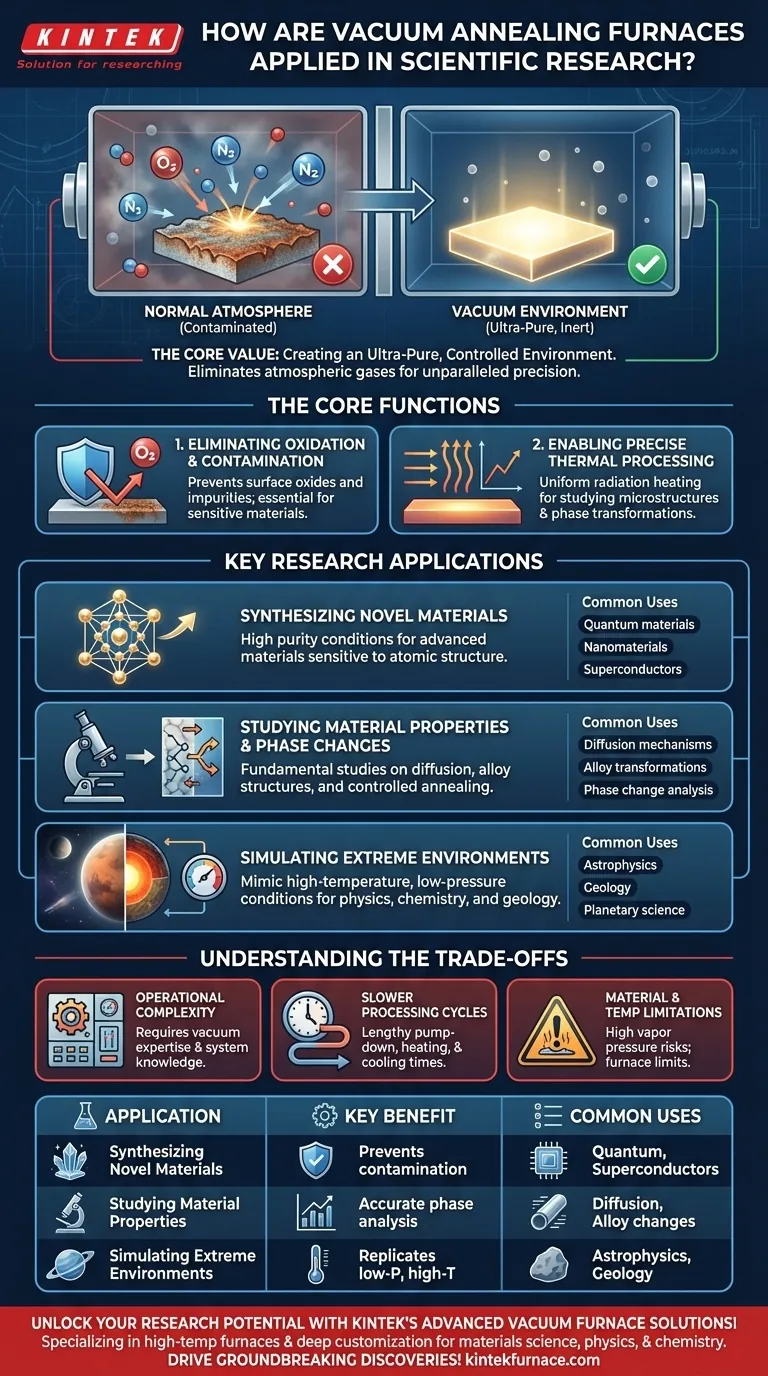

In scientific research, vacuum annealing furnaces are essential instruments used across materials science, physics, and chemistry to create and study materials in a highly controlled environment. They enable researchers to perform precise thermal treatments that would be impossible in a normal atmosphere, facilitating the synthesis of novel materials, the study of fundamental phase changes, and the simulation of extreme conditions.

The core value of a vacuum furnace in research is its ability to create an ultra-pure, inert environment. By removing atmospheric gases like oxygen and nitrogen, it eliminates unwanted chemical reactions, allowing scientists to study the intrinsic properties of a material with unparalleled precision.

The Core Function: Creating a Controlled Atmosphere

A vacuum furnace's primary role is not just to heat a sample, but to control the exact environment in which that heating occurs. This control is the foundation of its utility in academic and research settings.

Eliminating Oxidation and Contamination

The most critical function of the vacuum is to prevent oxidation. At high temperatures, most materials will readily react with oxygen, forming oxides on their surface that alter their physical, chemical, and electrical properties.

By removing the atmosphere, a vacuum furnace creates a chemically clean environment. This purity is essential when synthesizing sensitive materials like superconductors or nanomaterials, where even trace amounts of contamination can compromise the final product.

Enabling Precise Thermal Processing

Without an atmosphere, heat transfer occurs primarily through radiation, allowing for extremely uniform and predictable heating and cooling cycles.

This precision is vital for studying microstructural evolution and phase transformations. Researchers can program specific temperature ramps and holds to observe how a material's crystal structure changes, confident that the results are not being skewed by atmospheric interference.

Key Research Applications

The ability to create a pure, controlled thermal environment makes vacuum furnaces indispensable for a wide range of cutting-edge research.

Synthesizing Novel Materials

Vacuum furnaces provide the ideal conditions for preparing new materials that demand high purity. This is especially true for advanced materials whose properties are highly sensitive to their atomic structure.

Fields like quantum materials, nanomaterials, and superconducting materials rely heavily on this technology. The furnace promotes the intended material formation and crystal growth while preventing the formation of performance-degrading impurities.

Studying Material Properties and Phase Changes

In materials science, these furnaces are used to conduct fundamental studies on how materials behave. Researchers can investigate diffusion mechanisms, track how alloys change their structure (phase transformation), and optimize material performance through controlled annealing.

This allows scientists to build a foundational understanding of a material's properties, which is the first step toward developing new technologies.

Simulating Extreme Environments

Beyond material synthesis, vacuum furnaces are used to simulate conditions found elsewhere in the universe or deep within the Earth.

In physics and chemistry, they can mimic high-temperature and low-pressure environments to study material reactions. This is also applied in earth and planetary sciences to conduct simulation experiments that help explain geological processes.

Understanding the Trade-offs

While powerful, a vacuum furnace is a specialized tool with inherent limitations that researchers must consider for successful experimentation.

Operational Complexity

Operating a vacuum furnace is more complex than a standard atmospheric oven. It requires a working knowledge of vacuum pumps, pressure gauges, and control systems to ensure the desired environment is achieved and maintained safely.

Slower Processing Cycles

Achieving a high vacuum is a time-consuming process. The pump-down, heating, and subsequent cooling cycles under vacuum can take significantly longer than in an atmospheric furnace, which impacts experimental throughput.

Material and Temperature Limitations

Not all materials are suitable for vacuum processing. Materials with a high vapor pressure can outgas or even evaporate at high temperatures under vacuum, potentially contaminating the furnace and ruining the sample. The furnace's maximum temperature is also limited by its heating elements and chamber materials.

Making the Right Choice for Your Research Goal

Selecting the right thermal processing method depends entirely on your experimental objectives.

- If your primary focus is material purity and synthesis: A vacuum furnace is essential for creating high-purity samples like quantum materials, superconductors, or specific alloys without oxidation.

- If your primary focus is fundamental property analysis: The furnace provides the non-reactive environment needed to accurately study intrinsic properties like phase transformation temperatures and microstructural changes.

- If your primary focus is simulating specific conditions: The vacuum environment is a prerequisite for modeling low-pressure, high-temperature phenomena relevant to astrophysics or geology.

Ultimately, the vacuum furnace is an indispensable tool for moving beyond simple heating to true environmental control, enabling discovery at the frontiers of science.

Summary Table:

| Application | Key Benefit | Common Uses |

|---|---|---|

| Synthesizing Novel Materials | Prevents contamination for high purity | Quantum materials, superconductors, nanomaterials |

| Studying Material Properties | Enables accurate phase change analysis | Diffusion mechanisms, alloy transformations |

| Simulating Extreme Environments | Replicates low-pressure, high-temperature conditions | Astrophysics, geology, planetary science |

Unlock the potential of your research with KINTEK's advanced vacuum furnace solutions! We specialize in high-temperature furnaces, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, backed by exceptional R&D and in-house manufacturing. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether you're in materials science, physics, or chemistry. Contact us today to discuss how we can enhance your lab's efficiency and drive groundbreaking discoveries!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability