In chemical processing, silicon carbide (SiC) heating elements are primarily used for high-temperature reactions and processes that occur in harsh, corrosive environments. Applications like Chemical Vapor Deposition (CVD) rely on SiC elements because they can deliver precise, intense heat without degrading or contaminating the process, a feat traditional metal heaters cannot achieve.

The core value of silicon carbide in the chemical industry is its unique ability to solve two problems at once: it provides the extreme heat required for modern reactions while simultaneously resisting the aggressive chemical attacks that would destroy conventional heating elements.

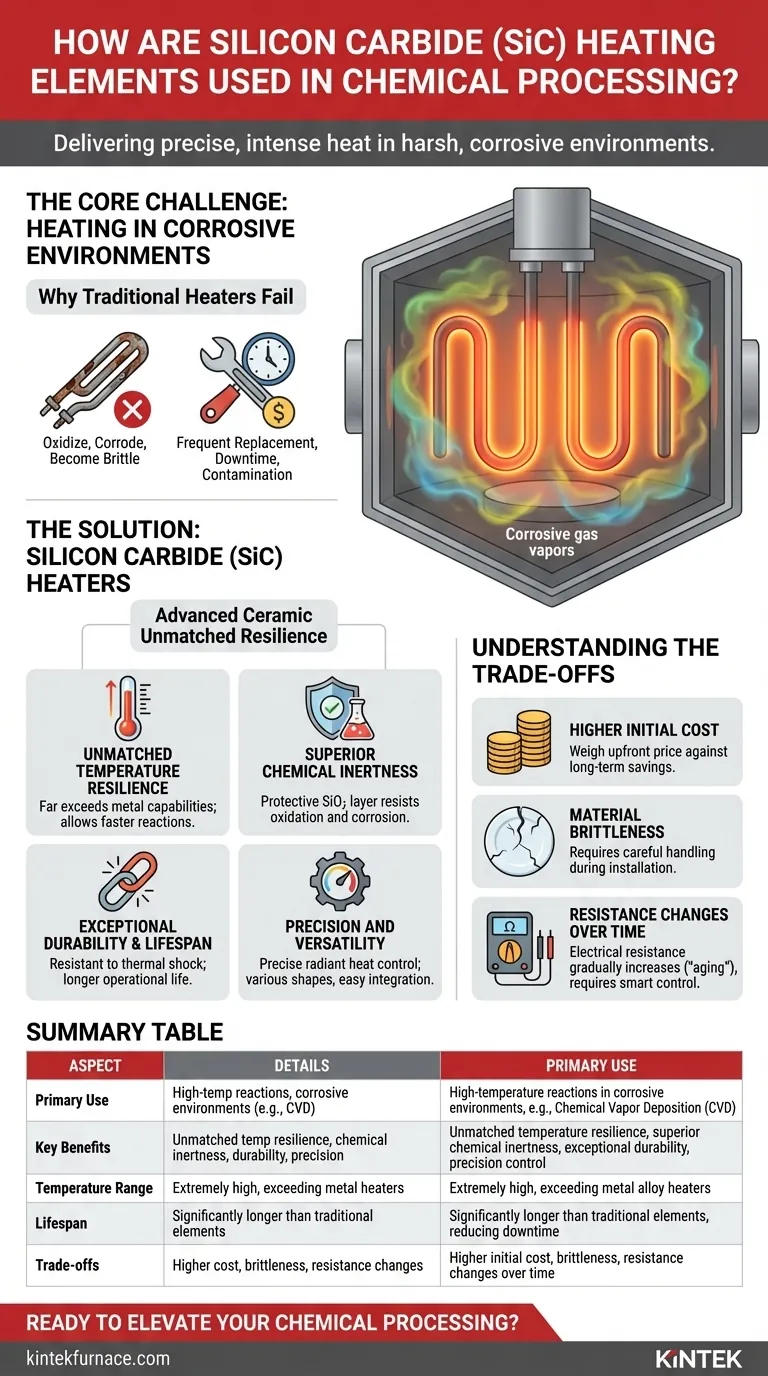

The Core Challenge: Heating in Corrosive Environments

In many chemical processes, heat is the catalyst for transformation. However, applying that heat is a significant engineering challenge when the environment is filled with reactive gases and vapors.

Why Traditional Heaters Fail

Most conventional heating elements are made from metal alloys. While effective at lower temperatures in neutral atmospheres, they quickly fail when exposed to the dual stresses of high heat and corrosive chemicals found in processes like CVD.

These metals oxidize, corrode, and become brittle, leading to frequent replacement, process downtime, and potential contamination of the final product.

The Need for a Superior Material

The chemical industry requires a heating solution that is not just hot, but also exceptionally resilient. The element must remain chemically stable (inert) and structurally sound, ensuring the purity and consistency of the reaction it enables.

How SiC Heaters Solve the Problem

Silicon carbide is not a metal but an advanced ceramic. Its fundamental material properties make it uniquely suited for the most demanding industrial heating applications.

Unmatched Temperature Resilience

SiC elements can operate at extremely high temperatures, far exceeding the capabilities of traditional metallic elements. This allows for faster reaction rates and the ability to process a wider range of materials.

This high-temperature performance is a direct result of the strong covalent bonds within the silicon carbide crystal structure.

Superior Chemical Inertness

During manufacturing, a protective layer of silicon dioxide (SiO₂) naturally forms on the surface of a SiC element. This layer is highly resistant to oxidation and chemical corrosion.

This "self-healing" protective film allows the element to function reliably for long periods in harsh chemical atmospheres without degrading or releasing contaminants.

Exceptional Durability and Lifespan

Compared to brittle metal alloys that have been exposed to heat and chemicals, SiC offers superior resistance to thermal shock. This means it can handle rapid heating and cooling cycles without cracking.

This robustness, combined with its chemical resistance, gives SiC heating elements a significantly longer operational life, reducing maintenance costs and increasing process uptime.

Precision and Versatility

SiC elements work by passing an electric current through the material, which generates intense radiant heat. The temperature can be controlled with high precision by adjusting the voltage or current supplied.

They are manufactured in various shapes, such as rods and spirals (often U-type), and can be mounted vertically or horizontally, making them easy to integrate into different reactor and furnace designs.

Understanding the Trade-offs

While SiC offers superior performance, it is essential to understand its specific engineering considerations. It is not a universal drop-in replacement for all heating applications.

Higher Initial Cost

As an advanced material, silicon carbide elements typically have a higher upfront purchase price than standard metal alloy heaters. This cost must be weighed against their longer lifespan and the reduced downtime they provide.

Material Brittleness

Like other ceramics, SiC is more brittle than metal. It requires more careful handling during installation and maintenance to prevent mechanical shock or fracture.

Resistance Changes Over Time

Over its long service life, a SiC element's electrical resistance will gradually increase. This "aging" is a predictable characteristic that must be managed by the power control system, which often requires a more sophisticated controller than one used for simple metallic elements.

Making the Right Choice for Your Process

Selecting the correct heating element is a critical decision that impacts process efficiency, reliability, and cost.

- If your primary focus is maximizing process temperature and purity: SiC is the definitive choice due to its high-temperature capability and unmatched chemical inertness.

- If your primary focus is navigating aggressive chemical vapors: SiC's inherent resistance to corrosion and oxidation provides stability and longevity where metals would inevitably fail.

- If your primary focus is balancing performance with budget: You must evaluate the total cost of ownership, weighing the higher initial cost of SiC against the significant savings from longer life and reduced process downtime.

Ultimately, selecting silicon carbide is an investment in process stability, reliability, and performance in the most demanding thermal environments.

Summary Table:

| Aspect | Details |

|---|---|

| Primary Use | High-temperature reactions in corrosive environments, e.g., Chemical Vapor Deposition (CVD) |

| Key Benefits | Unmatched temperature resilience, superior chemical inertness, exceptional durability, precision control |

| Temperature Range | Extremely high, exceeding metal alloy heaters |

| Lifespan | Significantly longer than traditional elements, reducing downtime |

| Trade-offs | Higher initial cost, brittleness, resistance changes over time |

Ready to elevate your chemical processing with reliable, high-performance heating solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems tailored for demanding environments. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're dealing with corrosive gases or require precise temperature control, our silicon carbide heating elements and other solutions ensure enhanced efficiency, reduced downtime, and superior results. Don't let heating challenges hold you back—contact us today to discuss how we can support your specific applications and drive your success!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the temperature range for silicon carbide heating elements? Unlock High-Temp Performance from 600°C to 1625°C

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency

- What types of heating elements are commonly used in drop tube furnaces? Find the Right Element for Your Temperature Needs

- What is silicon carbide used for in heating applications? Discover Its High-Temperature Durability