Yes, unequivocally. Silicon carbide (SiC) heating elements are engineered specifically for high-performance operation in extreme temperature and challenging atmospheric conditions. Their unique material properties make them a default choice for many demanding industrial heating applications where conventional metallic elements would quickly fail.

The core principle to understand is that SiC elements thrive in high-temperature, oxidizing environments due to a self-healing protective layer. However, their performance and longevity are critically dependent on the specific chemical atmosphere, as some conditions can actively degrade the material.

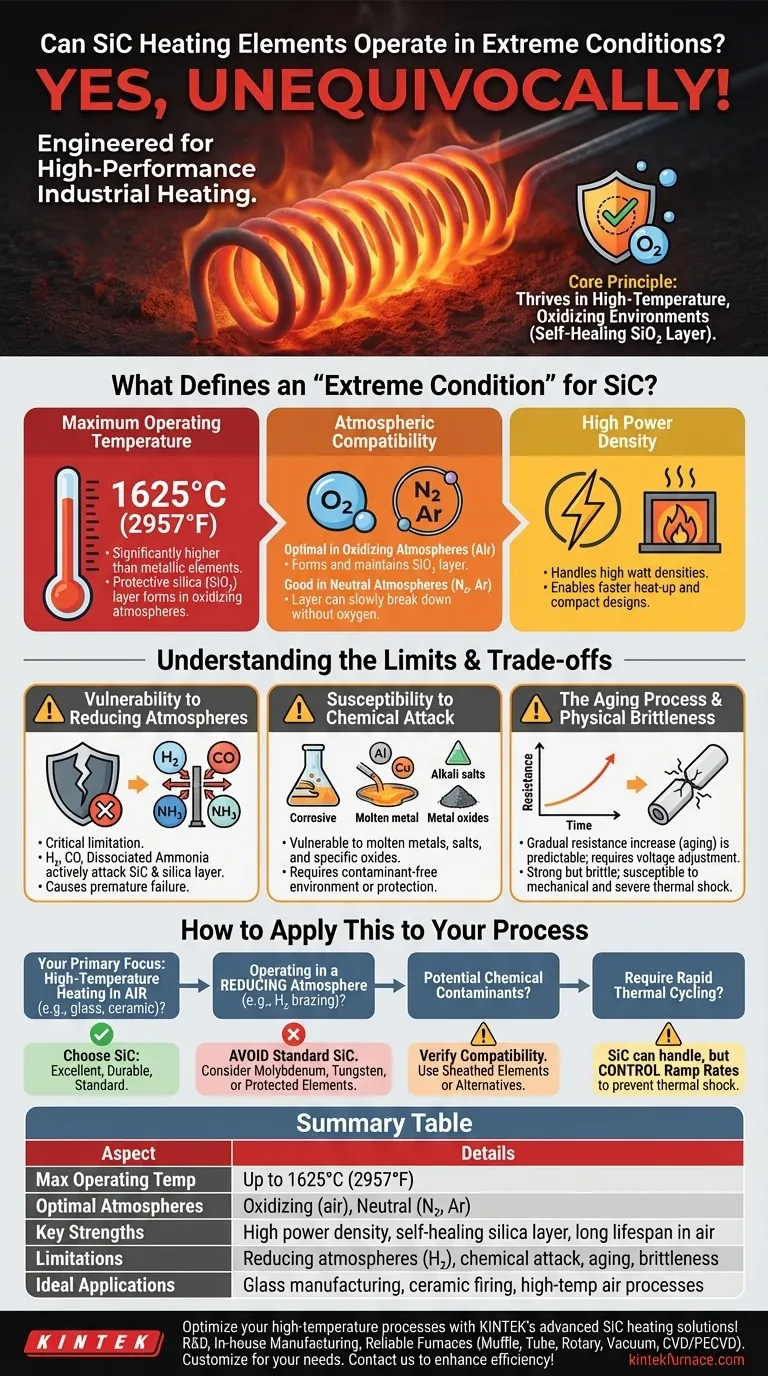

What Defines an "Extreme Condition" for SiC?

The term "extreme" is relative. For a heating element, it primarily involves high temperatures, aggressive atmospheres, and high power demands. SiC elements are designed to excel in these specific areas.

Maximum Operating Temperature

Silicon carbide elements can operate at surface temperatures up to 1625°C (2957°F). This is significantly higher than the limits of even the most advanced metallic elements.

This capability is thanks to the formation of a thin, protective layer of silica (SiO₂) on the element's surface when heated in the presence of oxygen. This layer acts as a barrier, preventing further rapid oxidation of the underlying SiC material.

Atmospheric Compatibility

SiC elements perform optimally and have the longest lifespan in oxidizing atmospheres, such as air. The presence of oxygen is what allows the protective SiO₂ layer to form and be maintained.

They can also operate in neutral atmospheres like nitrogen or argon. However, without oxygen to replenish the silica layer, any existing layer can slowly break down, especially at very high temperatures.

High Power Density

Due to their high operating temperature and robust nature, SiC elements can handle very high watt densities. This means they can radiate a large amount of energy from a relatively small surface area, enabling faster heat-up times and more compact furnace designs.

Understanding the Limits and Trade-offs

No material is perfect. The key to successful implementation is understanding the operational boundaries and potential failure modes of SiC.

Vulnerability to Reducing Atmospheres

This is the most critical limitation. Strong reducing atmospheres, such as hydrogen (H₂), dissociated ammonia, or carbon monoxide (CO), will actively attack both the SiC material and its protective silica layer.

In these environments, the silicon is stripped away, weakening the element, causing its resistance to change rapidly, and leading to premature failure.

Susceptibility to Chemical Attack

While generally robust, SiC elements are vulnerable to certain chemicals. Contact with molten metals (like aluminum or copper), alkali metal salts, and certain metal oxides (like lead or vanadium) can cause severe corrosion and rapid failure.

Care must be taken to ensure the process environment is free from these contaminants, or that the elements are adequately protected.

The Aging Process

All SiC elements experience aging, which is a gradual increase in their electrical resistance over time. This is caused by the slow growth of the crystalline structure within the material.

This is not a defect but a predictable characteristic. The power supply system must be designed to accommodate this by gradually increasing the voltage to the elements to maintain constant power output.

Physical Brittleness

Like most ceramics, SiC is strong but brittle. It can withstand immense heat but is susceptible to fracture from mechanical shock (being dropped or hit) or severe thermal shock (extremely rapid, non-uniform heating or cooling).

How to Apply This to Your Process

Choosing the right element requires matching its strengths and weaknesses to your specific operational environment.

- If your primary focus is high-temperature heating in air (e.g., glass manufacturing, ceramic firing): SiC is an industry-standard and an excellent choice due to its durability and high-temperature capability.

- If you are operating in a reducing atmosphere (e.g., hydrogen brazing, sintering): You must avoid standard SiC elements. Consider molybdenum, tungsten, or specially protected SiC elements.

- If your process involves potential chemical contaminants: You must verify chemical compatibility. If direct contact is unavoidable, a sheathed element or an alternative heating method may be necessary.

- If you require rapid thermal cycling: SiC can handle cycling well, but the ramp rates must be controlled to prevent thermal shock, especially in non-uniform furnace designs.

By understanding these core principles, you can confidently select and operate SiC elements to achieve reliable performance even in the most demanding conditions.

Summary Table:

| Aspect | Details |

|---|---|

| Max Operating Temperature | Up to 1625°C (2957°F) |

| Optimal Atmospheres | Oxidizing (e.g., air), neutral (e.g., nitrogen, argon) |

| Key Strengths | High power density, self-healing silica layer, long lifespan in air |

| Limitations | Vulnerable to reducing atmospheres (e.g., hydrogen), chemical attack, aging, brittleness |

| Ideal Applications | Glass manufacturing, ceramic firing, high-temperature processes in air |

Optimize your high-temperature processes with KINTEK's advanced SiC heating solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable, high-performance furnaces. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by deep customization to meet your unique experimental needs. Contact us today to enhance efficiency and durability in extreme conditions!

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the advantages of silicon carbide heating elements in dental furnaces? Boost Zirconia Sintering Quality

- What heating elements are used in high-temperature tube furnaces? Discover SiC and MoSi2 for Extreme Heat

- What parameters does the IEC standard specify for heating elements? Ensure Safety and Performance

- What temperature ranges are recommended for SiC versus MoSi2 heating elements? Optimize Your Furnace Performance

- What are the operational characteristics of SiC heating elements? Maximize High-Temp Performance and Efficiency