Yes, absolutely. Modern rotary kilns can be extensively automated to achieve a level of precision and efficiency that is difficult to sustain with manual control alone. This is accomplished by integrating a suite of technologies, including programmable logic controllers (PLCs), motor control centers (MCCs), and comprehensive data acquisition systems that work in concert to manage the entire process.

Automation transforms a rotary kiln from a manually-operated piece of equipment into a highly stable, self-regulating system. The goal is not just to replace operators, but to achieve a consistent thermal profile and operational state that maximizes output and minimizes energy consumption.

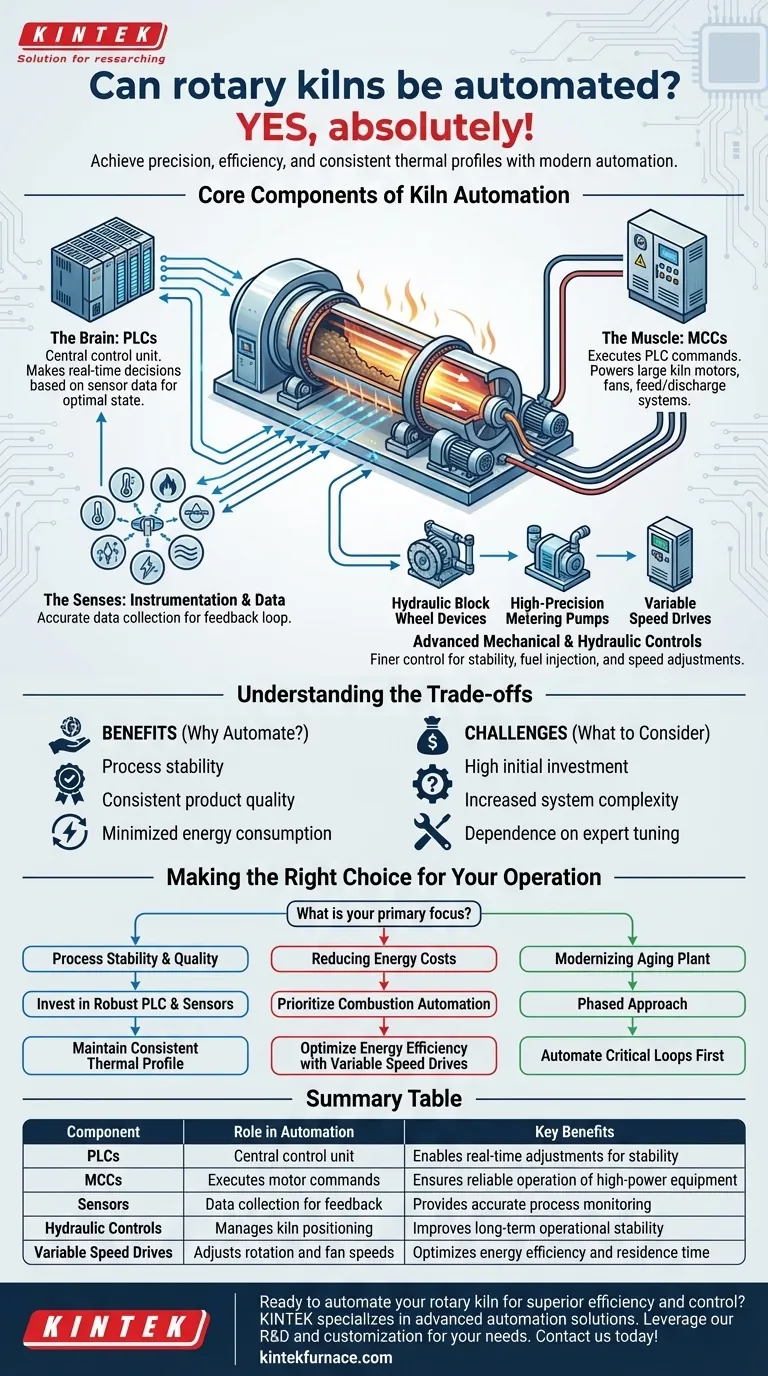

The Core Components of Kiln Automation

Automating a rotary kiln involves creating a closed-loop control system. This system uses digital "brains" to interpret data from sensors and make precise physical adjustments to the machinery.

The Brain: Programmable Logic Controllers (PLCs)

The PLC is the central nervous system of the automated kiln. It's a ruggedized industrial computer that runs the control logic.

Based on real-time data from sensors, the PLC makes constant decisions to adjust variables like rotational speed, fuel flow, and airflow to maintain a predefined, optimal state.

The Muscle: Motor Control Centers (MCCs)

The MCC acts as the interface between the PLC's low-voltage control signals and the high-power equipment.

It houses the starters, drives, and protection circuits for the large motors that rotate the kiln, power the draft fans, and operate feed and discharge systems. The PLC tells the MCC what to do, and the MCC executes the command.

The Senses: Instrumentation and Data Collection

For a PLC to make intelligent decisions, it needs accurate data. A network of sensors provides this information.

Key sensors typically measure the burning zone temperature, exhaust gas temperature and composition, kiln shell temperature, and material feed rate. This data is collected and fed back to the PLC in a continuous loop.

Advanced Mechanical and Hydraulic Controls

Automation also leverages modern mechanical components for finer control. This includes:

- Hydraulic Block Wheel Devices: These systems help manage the axial thrust of the kiln, ensuring it remains properly positioned on its rollers for stable, long-term operation.

- High-Precision Metering Pumps: Automated systems use these pumps for the precise injection of fuel or other additives, directly impacting thermal stability and product quality.

- Variable Speed Drives: Controlled by the PLC, these allow for precise adjustments to kiln rotation and fan speeds, which is critical for optimizing residence time and energy use.

Understanding the Trade-offs

While the benefits are significant, adopting automation requires a clear understanding of the associated challenges.

High Initial Investment

Implementing a full automation package requires significant capital. The cost includes not only the PLCs and MCCs but also the sensors, software engineering, installation, and commissioning.

Increased System Complexity

An automated kiln is a sophisticated system. It requires specialized knowledge for maintenance and troubleshooting. Your technical staff will need training to manage the control logic and diagnose issues that may arise.

Dependence on System Tuning

The effectiveness of an automated system is entirely dependent on the quality of its programming and tuning. A poorly configured control loop can perform worse than a skilled manual operator, potentially leading to process instability or equipment damage.

Making the Right Choice for Your Operation

The decision to automate should be driven by your specific operational goals.

- If your primary focus is process stability and product quality: Invest in a robust PLC system with comprehensive sensor integration to maintain a consistent thermal profile and residence time.

- If your primary focus is reducing energy costs: Prioritize automation of the combustion system, using variable speed drives on draft fans and precise fuel control to optimize energy efficiency.

- If your primary focus is modernizing an aging plant: A phased approach is often best, starting with automating the most critical control loops first (like kiln speed and draft) before moving to a fully integrated system.

By leveraging automation, you gain direct and precise control over one of the most critical processes in your facility.

Summary Table:

| Component | Role in Automation | Key Benefits |

|---|---|---|

| PLCs | Central control unit | Enables real-time adjustments for stability |

| MCCs | Executes motor commands | Ensures reliable operation of high-power equipment |

| Sensors | Data collection for feedback | Provides accurate process monitoring |

| Hydraulic Controls | Manages kiln positioning | Improves long-term operational stability |

| Variable Speed Drives | Adjusts rotation and fan speeds | Optimizes energy efficiency and residence time |

Ready to automate your rotary kiln for superior efficiency and control? KINTEK specializes in high-temperature furnace solutions, including advanced automation for rotary kilns. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique operational needs. Contact us today to discuss how we can enhance your process with tailored automation systems!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

People Also Ask

- What are some drying applications of electromagnetic rotary kilns? Discover Efficient, Precise Drying Solutions

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource