In the precision-driven world of material science and dental laboratories, the user-friendliness of a sintering furnace is not a minor convenience—it is a critical factor for success. A well-designed interface directly enhances operational efficiency, minimizes costly mistakes, and ensures the consistent quality of the final product. It transforms a complex thermal process into a reliable, repeatable, and accessible task for all lab personnel.

Sintering is an exacting process where small deviations can lead to complete failure. A user-friendly furnace is not a luxury but a fundamental control system that mitigates the primary source of inconsistency: human error. It safeguards material investments, saves technician time, and guarantees predictable outcomes.

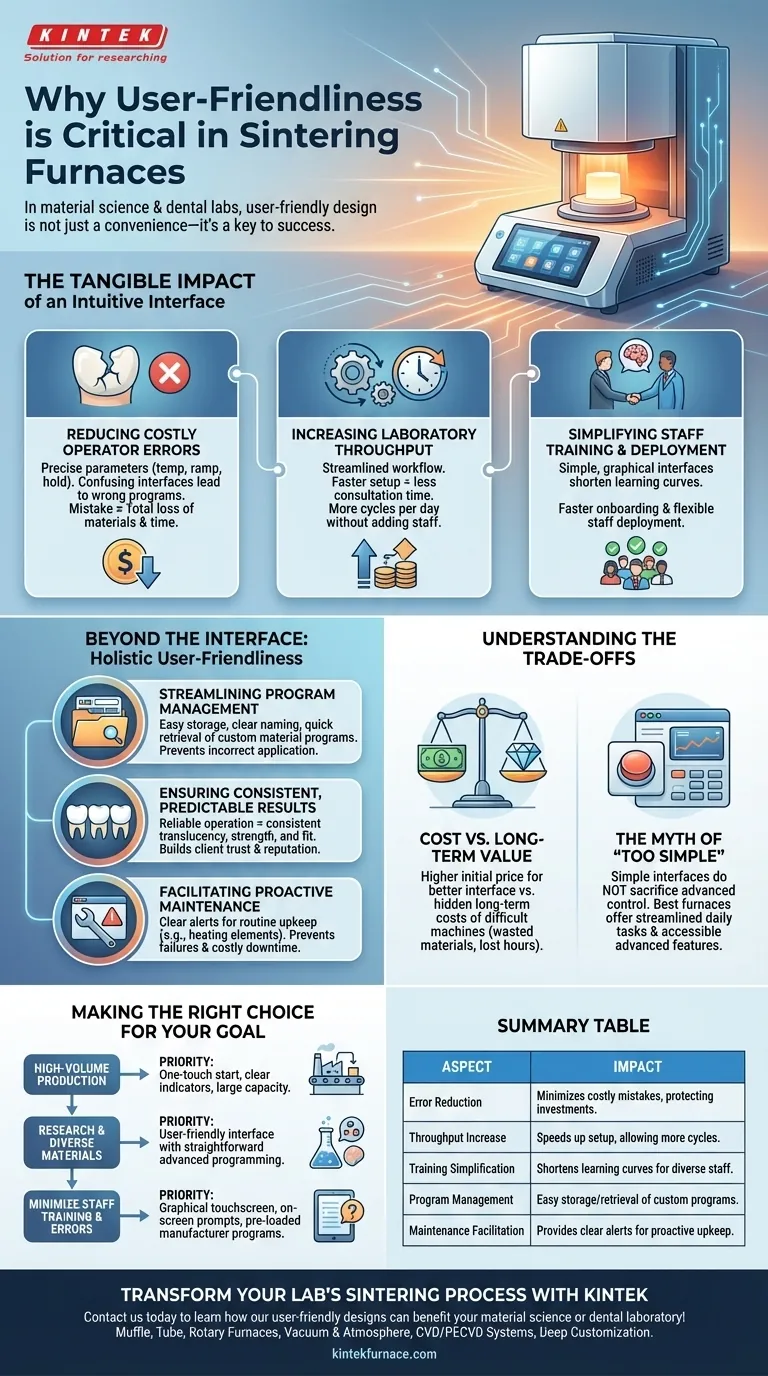

The Tangible Impact of an Intuitive Interface

The design of a furnace's control system has a direct and measurable effect on a laboratory's daily operations, profitability, and quality of work.

Reducing Costly Operator Errors

Sintering cycles are defined by precise parameters, including temperatures, ramp rates, and hold times. A confusing or poorly designed interface makes it easy for a technician to select the wrong program or input incorrect data.

This single mistake can ruin an entire batch of restorations or material samples, resulting in a total loss of material costs and the valuable time spent in preparation.

Increasing Laboratory Throughput

An intuitive furnace streamlines the workflow. When technicians can set up and start a cycle quickly and confidently, they spend less time consulting manuals or double-checking their work.

This acceleration of the setup process means more cycles can be run per day, directly increasing the lab's overall capacity and throughput without adding staff.

Simplifying Staff Training and Deployment

Laboratories often employ technicians with diverse backgrounds and technical skill levels. A furnace with a simple, graphical interface shortens the learning curve significantly.

This reduces the time required to onboard new staff and allows for more flexible deployment of personnel, as more team members can be trusted to operate the furnace correctly.

Beyond the Interface: Holistic User-Friendliness

True user-friendliness extends beyond the screen to encompass the entire workflow, from programming to maintenance.

Streamlining Program Management

Modern labs and research facilities use a wide array of materials, each requiring a unique sintering program. An effective furnace allows for the easy storage, clear naming, and quick retrieval of these custom programs.

This organizational capability is crucial for preventing a technician from accidentally applying a zirconia program to a different ceramic, which would lead to a failed result.

Ensuring Consistent, Predictable Results

The ultimate goal of any sintering process is a predictable outcome. When the furnace is easy to operate correctly every single time, the final properties of the material—such as the translucency, strength, and fit of a dental crown—become highly consistent.

This reliability builds trust with clients and solidifies a lab's reputation for quality.

Facilitating Proactive Maintenance

A well-designed system incorporates clear, easy-to-understand alerts for routine maintenance, such as replacing heating elements or thermocouples.

This proactive approach prevents unexpected equipment failure and costly downtime, ensuring the furnace is always operating at peak accuracy and efficiency.

Understanding the Trade-offs

Evaluating a furnace based on user-friendliness requires looking past the initial price tag and understanding the long-term value.

Cost vs. Long-Term Value

A furnace with a superior, user-friendly interface may command a higher initial purchase price. This can seem like an unnecessary expense.

However, this initial cost must be weighed against the hidden, long-term costs of a difficult-to-use machine, which include wasted materials, lost technician hours, process delays, and the financial impact of remaking failed jobs.

The Myth of "Too Simple"

Some experts may worry that a "user-friendly" furnace sacrifices advanced control for simplicity. This is a false choice.

The best modern furnaces provide a simple, streamlined interface for daily, routine tasks while keeping advanced customization and programming capabilities easily accessible for expert users when needed.

Making the Right Choice for Your Goal

When selecting a sintering furnace, align its user-centric features with your laboratory's primary objectives.

- If your primary focus is high-volume production: Prioritize a furnace with one-touch program starts, clear status indicators, and large capacity to maximize throughput and minimize the risk of batch errors.

- If your primary focus is research or working with diverse materials: Seek a user-friendly interface that still provides straightforward access to advanced programming for creating and modifying custom cycles.

- If your primary focus is minimizing staff training and errors: Choose a furnace with a graphical touchscreen, clear on-screen prompts, and pre-loaded manufacturer programs for common materials.

Ultimately, a user-friendly furnace is an investment that transforms a critical, complex process into your lab's most reliable and efficient asset.

Summary Table:

| Aspect | Impact |

|---|---|

| Error Reduction | Minimizes costly mistakes in sintering cycles, protecting material investments. |

| Throughput Increase | Speeds up setup and operation, allowing more cycles per day. |

| Training Simplification | Shortens learning curves for staff with diverse skill levels. |

| Program Management | Enables easy storage and retrieval of custom programs for various materials. |

| Maintenance Facilitation | Provides clear alerts for proactive upkeep, reducing downtime. |

Transform your lab's sintering process with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique needs. Reduce errors, boost efficiency, and ensure consistent quality—contact us today to learn how our user-friendly designs can benefit your material science or dental laboratory!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab