The defining advantage of PECVD is its ability to operate at significantly lower temperatures than conventional Chemical Vapor Deposition (CVD). By using plasma instead of high heat to drive the necessary chemical reactions, PECVD can deposit thin films onto temperature-sensitive materials like plastics and polymers without causing them to melt, deform, or degrade.

The core challenge in coating sensitive materials is that traditional deposition methods require extreme heat, which would destroy the substrate. PECVD solves this by replacing brute-force thermal energy with the targeted energy of a plasma, enabling high-quality coatings at temperatures low enough to be safe for plastics and other delicate materials.

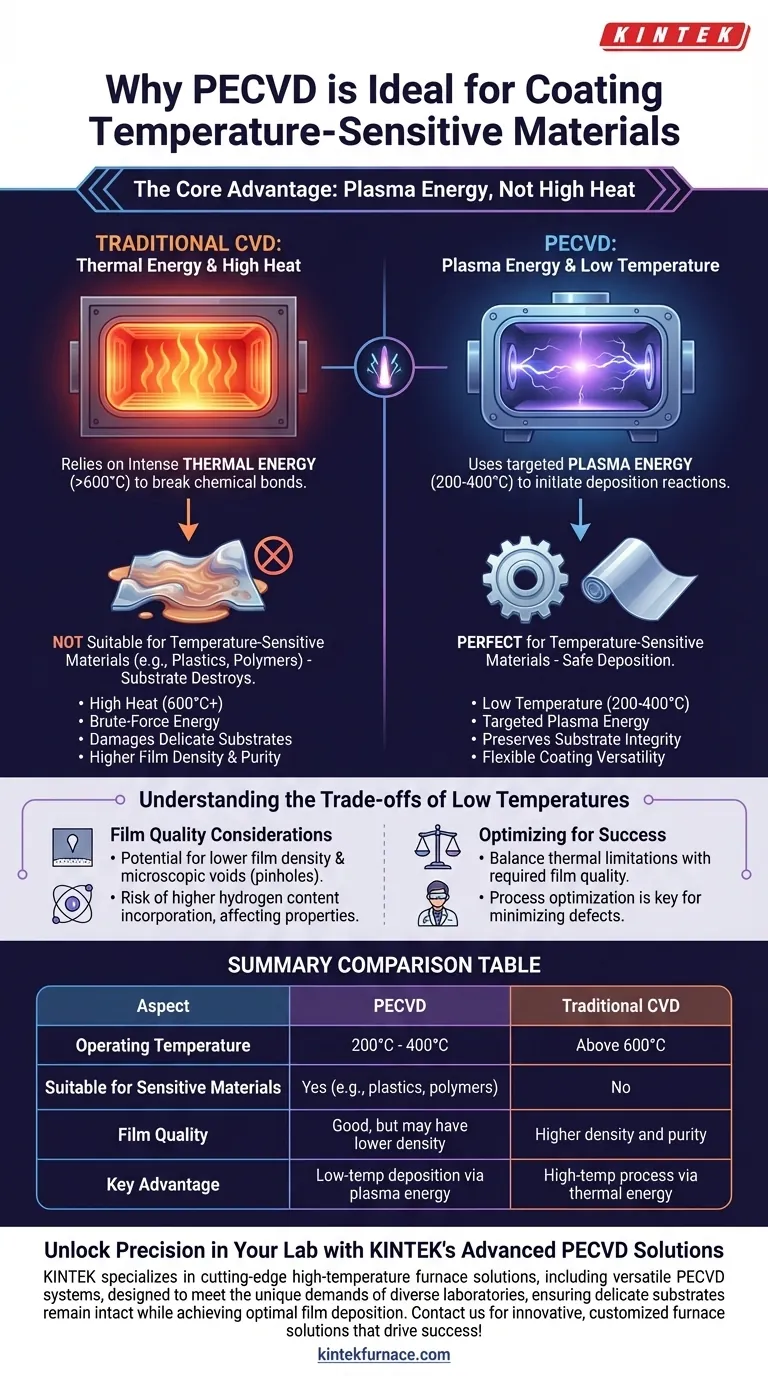

The Core Principle: Plasma vs. Thermal Energy

To understand why PECVD is so effective, you must first grasp the fundamental difference in how it supplies energy compared to its traditional counterpart.

How Traditional CVD Works

Traditional Chemical Vapor Deposition (CVD) relies purely on thermal energy. Precursor gases are introduced into a high-temperature furnace, typically operating above 600°C.

This intense heat provides the activation energy needed to break the chemical bonds in the gases, allowing them to react and deposit as a solid thin film on a substrate.

The PECVD Alternative: Plasma Energy

Plasma-Enhanced Chemical Vapor Deposition (PECVD) generates this activation energy in a completely different way. It operates within a vacuum chamber at a much lower temperature, usually between 200°C and 400°C.

Instead of just heat, an electric field is applied to the precursor gases, stripping electrons from atoms and creating a plasma. This plasma is a highly energetic state of matter containing ions and free electrons.

The Result: A Low-Temperature Process

The energetic particles within the plasma collide with the precursor gas molecules. These collisions transfer enough energy to break chemical bonds and initiate the deposition reaction.

Because the plasma provides the necessary energy, the system no longer depends on extreme heat. This is the key mechanism that allows PECVD to successfully coat materials that cannot withstand the high temperatures of conventional CVD.

Understanding the Trade-offs of Lower Temperatures

While the low-temperature capability of PECVD is its primary advantage, it is not without compromises. The deposition temperature directly influences the quality of the final film.

Film Quality and Temperature

As a general rule, films deposited at higher temperatures are of higher quality. They tend to be denser, more stable, and have fewer impurities.

Lowering the deposition temperature in PECVD, while necessary for sensitive substrates, can impact the final film's characteristics.

The Risk of Pinholes and Defects

Films grown at the lower end of the PECVD temperature range are more prone to being less dense and may contain microscopic voids or pinholes.

This lower density can affect the film's performance as a barrier layer and may require process optimization to mitigate.

Hydrogen Content and Its Impact

In many PECVD processes, such as depositing silicon nitride (SiN) or silicon dioxide (SiO₂), precursor gases contain hydrogen. At lower temperatures, more of this hydrogen can become incorporated into the growing film.

This residual hydrogen can alter the film's electrical properties, optical transparency, and mechanical stress, which is a critical consideration for applications in microelectronics and optics.

Making the Right Choice for Your Goal

Your choice of deposition method must balance the thermal limitations of your substrate against the required quality and purity of the thin film.

- If your primary focus is preserving a temperature-sensitive substrate: PECVD is the superior and often only choice, but you must be prepared to optimize the process to minimize defects associated with lower temperatures.

- If your primary focus is achieving the highest possible film density and purity: A higher-temperature process like traditional CVD is preferable, provided your substrate can tolerate the intense heat.

- If your primary focus is coating versatility: PECVD is exceptionally flexible, capable of depositing a wide range of materials including oxides, nitrides, and even polymers onto various substrates.

By understanding the fundamental trade-off between temperature and film quality, you can confidently select the deposition method that best aligns with your project's constraints and goals.

Summary Table:

| Aspect | PECVD | Traditional CVD |

|---|---|---|

| Operating Temperature | 200°C - 400°C | Above 600°C |

| Suitable for Temperature-Sensitive Materials | Yes (e.g., plastics, polymers) | No |

| Film Quality | Good, but may have lower density and hydrogen content | Higher density and purity |

| Key Advantage | Uses plasma energy for low-temperature deposition | Relies on thermal energy for high-temperature processes |

Unlock Precision in Your Laboratory with KINTEK's Advanced PECVD Solutions

Are you working with temperature-sensitive materials like plastics or polymers and need reliable, high-quality coatings without the risk of damage? KINTEK specializes in cutting-edge high-temperature furnace solutions, including our versatile PECVD systems, designed to meet the unique demands of diverse laboratories.

-

Why Choose KINTEK? We leverage exceptional R&D and in-house manufacturing to deliver advanced PECVD systems that operate at low temperatures (200°C - 400°C), ensuring your delicate substrates remain intact while achieving optimal film deposition. Our strong deep customization capability allows us to tailor solutions precisely to your experimental requirements, whether you're in microelectronics, optics, or materials science.

-

Our Product Line: Beyond PECVD, we offer a comprehensive range including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all built to enhance efficiency and accuracy in your lab.

Don't let thermal limitations hold back your research—partner with KINTEK for innovative, customized furnace solutions that drive success. Contact us today to discuss how we can support your specific needs and elevate your laboratory's capabilities!

Visual Guide

Related Products

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is silicon dioxide deposited from tetraethylorthosilicate (TEOS) in PECVD? Achieve Low-Temperature, High-Quality SiO2 Films

- What is resistance heating and how is it classified? Discover the Best Method for Your Thermal Needs

- What is PECVD specification? A Guide to Choosing the Right System for Your Lab

- What parameters control the quality of PECVD-deposited films? Master Key Variables for Superior Film Properties

- What are the classifications of CVD based on vapor characteristics? Optimize Your Thin Film Deposition Process