Choosing the right dental furnace is not merely a preference; it is a clinical and technical necessity. The furnace must be perfectly matched to the material's specific processing requirements to achieve the intended physical properties, aesthetic qualities, and long-term durability of a dental restoration. Using an incompatible furnace or incorrect settings directly compromises the final outcome, leading to failures in both function and appearance.

A dental furnace is not a simple oven. It is a precision instrument engineered to execute complex thermal cycles that are unique to each class of dental material. The central challenge is ensuring the furnace can replicate these specific temperature, time, and atmospheric conditions with absolute accuracy, as any deviation can ruin the restoration.

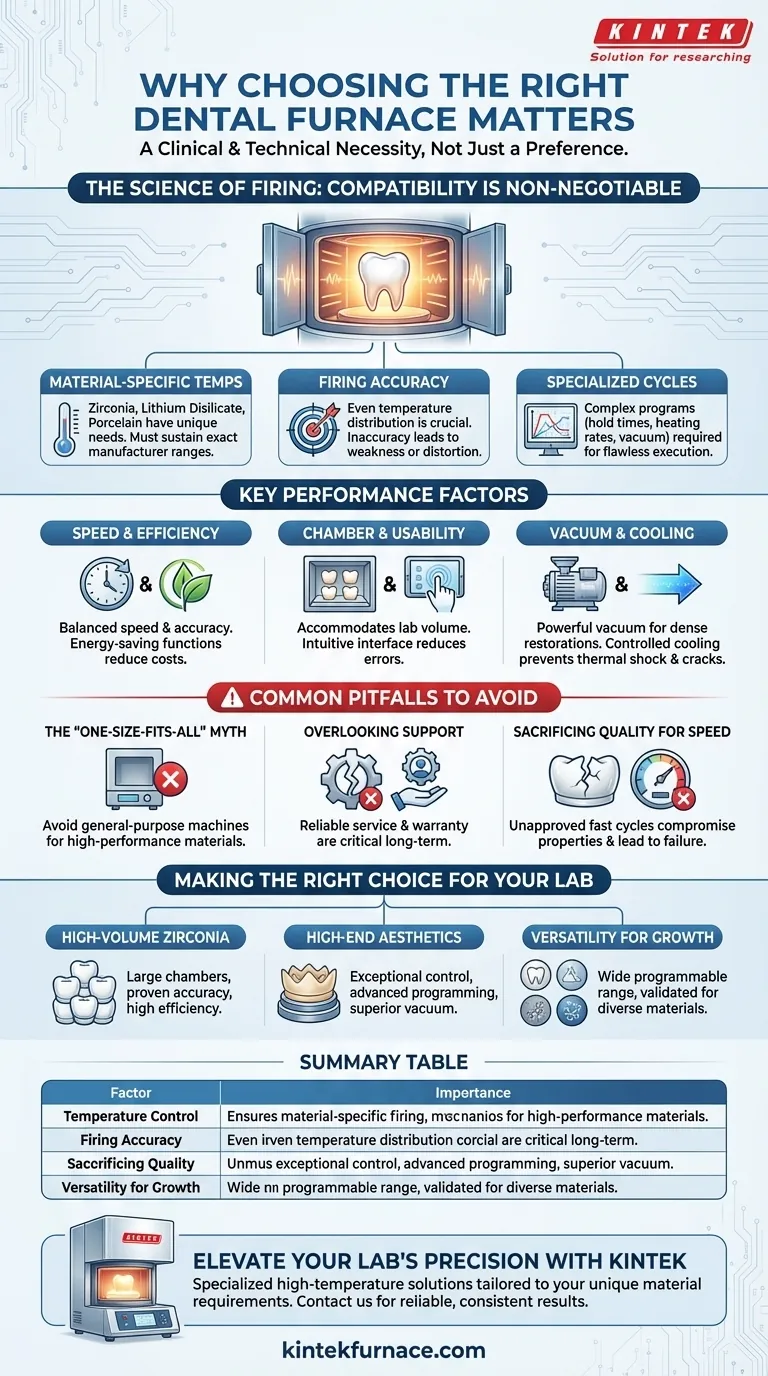

The Science of Firing: Why Compatibility is Non-Negotiable

The success of a ceramic restoration is determined in the furnace. The firing process transforms the milled, layered, or pressed material into its final, high-strength state. This transformation is highly sensitive and demands precise control.

Material-Specific Temperature Demands

Different materials, such as zirconia, lithium disilicate, or layered porcelain, have unique and non-negotiable firing temperatures. For instance, the temperatures required to sinter zirconia are vastly different from those needed to glaze a lithium disilicate crown.

A furnace must be capable of reaching and sustaining the exact temperature range required by the material manufacturer.

The Importance of Firing Accuracy

It's not enough to simply reach a peak temperature. The furnace must provide even temperature distribution throughout its chamber to ensure the entire restoration is processed uniformly.

Infrared sensors and advanced control systems enhance this reliability, guaranteeing that the programmed temperature is the actual temperature the ceramic experiences. Inaccuracy leads to under-fired weakness or over-fired distortion.

Specialized Firing Cycles

Modern restorations require more than a simple heat-up and cool-down. Many materials demand complex programs involving multiple stages, controlled heating rates, specific "hold" times, and precise vacuum levels to prevent porosity.

The furnace’s software and programmability must be robust enough to execute these intricate cycles flawlessly for different materials.

Understanding the Key Performance Factors

Beyond basic temperature compatibility, several technical features differentiate a workhorse furnace from one that creates problems. Evaluating these factors is essential for making a sound investment.

Speed and Energy Efficiency

The speed of a firing cycle directly impacts a lab's daily throughput and productivity. However, speed must be balanced with accuracy.

Modern furnaces also incorporate energy-saving functions that can significantly reduce operational costs over the furnace's lifetime.

Chamber Size and Ease of Use

The furnace chamber size must accommodate the volume and type of work your lab produces. A small chamber may become a bottleneck in a high-production environment.

Furthermore, a furnace with an intuitive touchscreen interface and user-friendly software reduces the risk of human error and simplifies workflow.

Vacuum and Cooling Systems

For many porcelains, a powerful and responsive vacuum system is critical for creating dense, void-free restorations.

Equally important is the cooling system. Controlled, gradual cooling prevents thermal shock that can introduce internal stresses and micro-cracks, compromising the restoration's structural integrity.

Common Pitfalls to Avoid

Choosing a furnace based on price alone is a frequent and costly mistake. The long-term value is determined by reliability, support, and the quality of the final product.

The "One-Size-Fits-All" Myth

Be cautious of furnaces that claim to be perfect for every material without demonstrating specialized features. A general-purpose machine may lack the precise control needed for high-performance aesthetic materials.

Overlooking Post-Sale Support

A furnace is a long-term investment. The manufacturer's reputation, warranty coverage, and access to reliable customer and technical support are critical. A furnace that cannot be serviced quickly becomes an expensive paperweight.

Sacrificing Quality for Speed

While fast firing cycles are attractive for productivity, they must be validated by the material manufacturer. Using an unapproved "fast" cycle can compromise the material's properties and lead to premature clinical failure.

Making the Right Choice for Your Lab

Your decision should be guided by your lab's specific goals and the primary materials you work with.

- If your primary focus is high-volume zirconia production: Prioritize furnaces with large chambers, proven sintering accuracy, and high energy efficiency to maximize throughput.

- If your primary focus is high-end aesthetic restorations: Invest in a furnace with exceptional temperature control, advanced programmability, and a superior vacuum system for layered porcelains and lithium disilicate.

- If your primary focus is versatility for a growing practice: Select a furnace with a wide programmable range and robust software that is validated for a diverse portfolio of common dental materials.

By precisely aligning your furnace's capabilities with your material requirements, you ensure predictable, high-quality outcomes for every restoration you create.

Summary Table:

| Factor | Importance |

|---|---|

| Temperature Control | Ensures material-specific firing for strength and aesthetics |

| Firing Accuracy | Prevents under-fired weakness or over-fired distortion |

| Specialized Cycles | Supports complex programs for materials like zirconia and porcelain |

| Vacuum System | Creates dense, void-free restorations |

| Cooling System | Avoids thermal shock and micro-cracks |

| Chamber Size | Matches lab production volume and workflow |

Ready to elevate your dental lab's precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our deep customization capabilities, we tailor each furnace to meet your unique material requirements—whether you're focused on high-volume zirconia, aesthetic restorations, or versatile practice growth. Contact us today to discuss how our reliable, energy-efficient furnaces can deliver consistent, high-quality results for your dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are some key features of dental sintering and porcelain furnaces? Optimize Your Dental Lab's Workflow

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What safety measures should be followed when using a sintering furnace in dental labs? Ensure Safe, High-Quality Dental Restorations