The definitive answer is that neither PVD nor CVD is universally "better." The superior method depends entirely on your specific application's requirements for film properties, geometry, and material. Physical Vapor Deposition (PVD) excels at creating highly pure, dense, and durable coatings on relatively simple surfaces. In contrast, Chemical Vapor Deposition (CVD) is the superior choice for creating exceptionally uniform and conformal layers over complex, three-dimensional geometries.

The choice between PVD and CVD is not about picking a winner, but about matching the deposition mechanism to your project's most critical outcome. You must decide if your priority is the physical transfer of a pure material (PVD) or a chemically-reacted, perfectly conforming film (CVD).

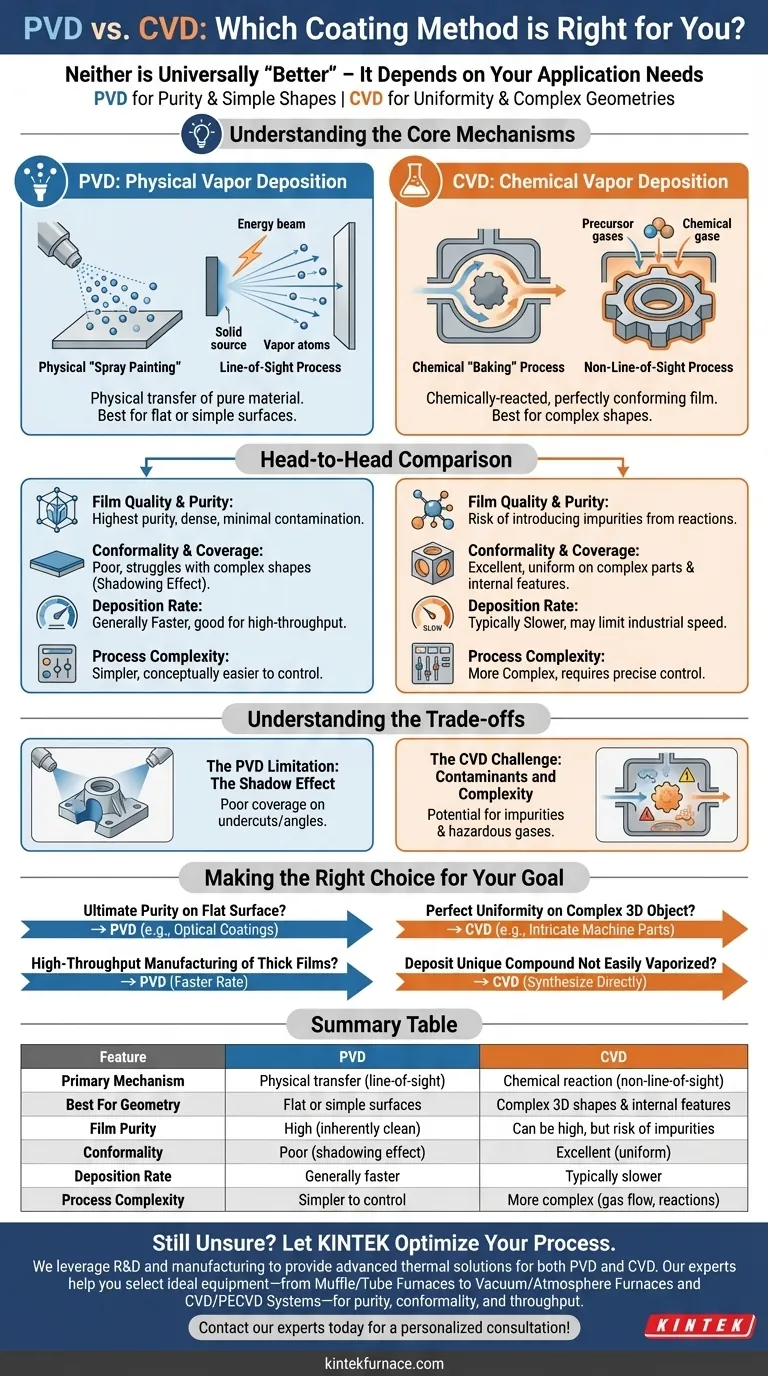

Understanding the Core Mechanisms

To make an informed decision, you must first understand how fundamentally different these two processes are. They are not interchangeable; they are distinct tools for different tasks.

PVD: A Physical "Spray Painting" Process

Think of Physical Vapor Deposition (PVD) as a highly sophisticated form of spray painting in a vacuum. A solid source material is vaporized through physical means (like heating or ion bombardment). This vapor then travels in a straight line through a high-vacuum chamber and condenses onto the substrate, forming a thin film.

The key takeaway is that this is a line-of-sight process. The atoms or molecules of the coating material travel directly from the source to the target.

CVD: A Chemical "Baking" Process

Chemical Vapor Deposition (CVD), on the other hand, is like baking a cake. Precursor gases containing the desired elements are introduced into a reaction chamber. Heat or pressure causes these gases to react on the substrate's surface, "building" the desired film atom by atom as a byproduct of the chemical reaction.

This is a non-line-of-sight process. Because the deposition happens from a gas phase, it can uniformly coat all exposed surfaces, including complex shapes and internal features.

PVD vs. CVD: A Head-to-Head Comparison

Each mechanism's nature creates distinct advantages and disadvantages across several critical performance metrics.

Film Quality and Purity

PVD starts with a highly pure solid material and simply transfers it to the substrate. This makes it an inherently clean process, excellent for applications demanding the highest purity and density with minimal contamination.

CVD relies on chemical reactions, which can sometimes leave behind residual chemicals or byproducts in the film. While high purity is achievable with precise process control and pure precursors, there is a greater inherent risk of introducing impurities.

Conformality and Coverage

This is the most significant point of divergence. CVD excels at conformality, meaning it can produce a film of uniform thickness over complex, non-flat geometries, and even inside deep trenches or holes.

PVD's line-of-sight nature means it struggles with complex shapes. Areas not directly facing the source material will receive little to no coating, creating a "shadowing" effect. It is best suited for flat or gently curved surfaces.

Deposition Rate and Speed

PVD processes generally offer faster deposition rates than CVD. This makes PVD more suitable for applications requiring thick films or high-throughput manufacturing where speed is a critical factor.

CVD is typically a slower process, which can be a limitation for industrial-scale production that demands rapid turnaround.

Process Complexity

The steps in PVD (vaporization and condensation) are conceptually simpler and often easier to control. The primary variables are temperature, time, and chamber pressure.

CVD is a more complex process to manage. It requires precise control over multiple precursor gas concentrations, flow rates, chamber pressure, and temperature to ensure the correct chemical reaction occurs uniformly.

Understanding the Trade-offs

Choosing a method requires acknowledging its inherent limitations. Your decision must be based on which trade-off is more acceptable for your project.

The PVD Limitation: The Shadow Effect

The primary trade-off with PVD is its poor coverage on complex parts. If your component has undercuts, internal channels, or sharp angles, PVD will not provide a uniform coating. This is a non-negotiable physical constraint of the line-of-sight process.

The CVD Challenge: Contaminants and Complexity

The main trade-off with CVD is the potential for impurities and process defects. The chemical reactions must be perfectly controlled to avoid incorporating unwanted elements from the precursor gases. Furthermore, these gases can be hazardous and require significant safety and handling infrastructure.

The Question of Adhesion and Durability

PVD films are often deposited with high kinetic energy, which can result in very dense films with excellent adhesion and durability.

While CVD films also offer good adhesion, the density and hardness can be more variable and highly dependent on the specific chemical process used.

Making the Right Choice for Your Goal

To select the correct method, align your primary objective with the process best suited to achieve it.

- If your primary focus is ultimate purity and density on a flat or simple surface: PVD is your most direct and reliable path for applications like optical coatings or basic semiconductor layers.

- If your primary focus is a perfectly uniform coating on a complex, 3D object: CVD is the only choice due to its superior conformality, ideal for coating internal pipes or intricate machine parts.

- If your primary focus is high-throughput manufacturing of thick films: PVD's typically faster deposition rate offers a significant advantage for production efficiency.

- If your primary focus is depositing a unique compound not easily vaporized: CVD's use of precursor gases provides more flexibility to synthesize materials directly on the substrate.

By understanding their fundamental differences, you move from asking "which is better?" to knowing "which is right for my goal."

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Primary Mechanism | Physical transfer (line-of-sight) | Chemical reaction (non-line-of-sight) |

| Best For Geometry | Flat or simple surfaces | Complex 3D shapes & internal features |

| Film Purity | High (inherently clean process) | Can be high, but risk of impurities |

| Conformality | Poor (shadowing effect) | Excellent (uniform on complex parts) |

| Deposition Rate | Generally faster | Typically slower |

| Process Complexity | Simpler to control | More complex (gas flow, reactions) |

Still Unsure Which Coating Method is Right for Your Project?

At KINTEK, we leverage our exceptional R&D and in-house manufacturing to provide advanced thermal solutions for diverse laboratory and industrial needs. Our expertise extends to supporting both PVD and CVD processes with our high-performance furnaces.

Whether you are coating simple flat substrates or complex 3D components, our team can help you select and customize the ideal equipment—from Muffle and Tube Furnaces to sophisticated Vacuum & Atmosphere Furnaces and CVD/PECVD Systems—to meet your unique requirements for purity, conformality, and throughput.

Let's optimize your deposition process. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- What is plasma enhanced chemical vapor deposition application? Enable High-Performance Thin Films at Lower Temperatures

- What role does PECVD play in optical coatings? Essential for Low-Temp, High-Precision Film Deposition

- What is the second benefit of deposition within a discharge in PECVD? Enhance Film Quality with Ion Bombardment

- How does plasma vapor deposition work? A Low-Temperature Solution for Advanced Coatings

- What is PECVD and how does it differ from traditional CVD? Unlock Low-Temperature Thin Film Deposition