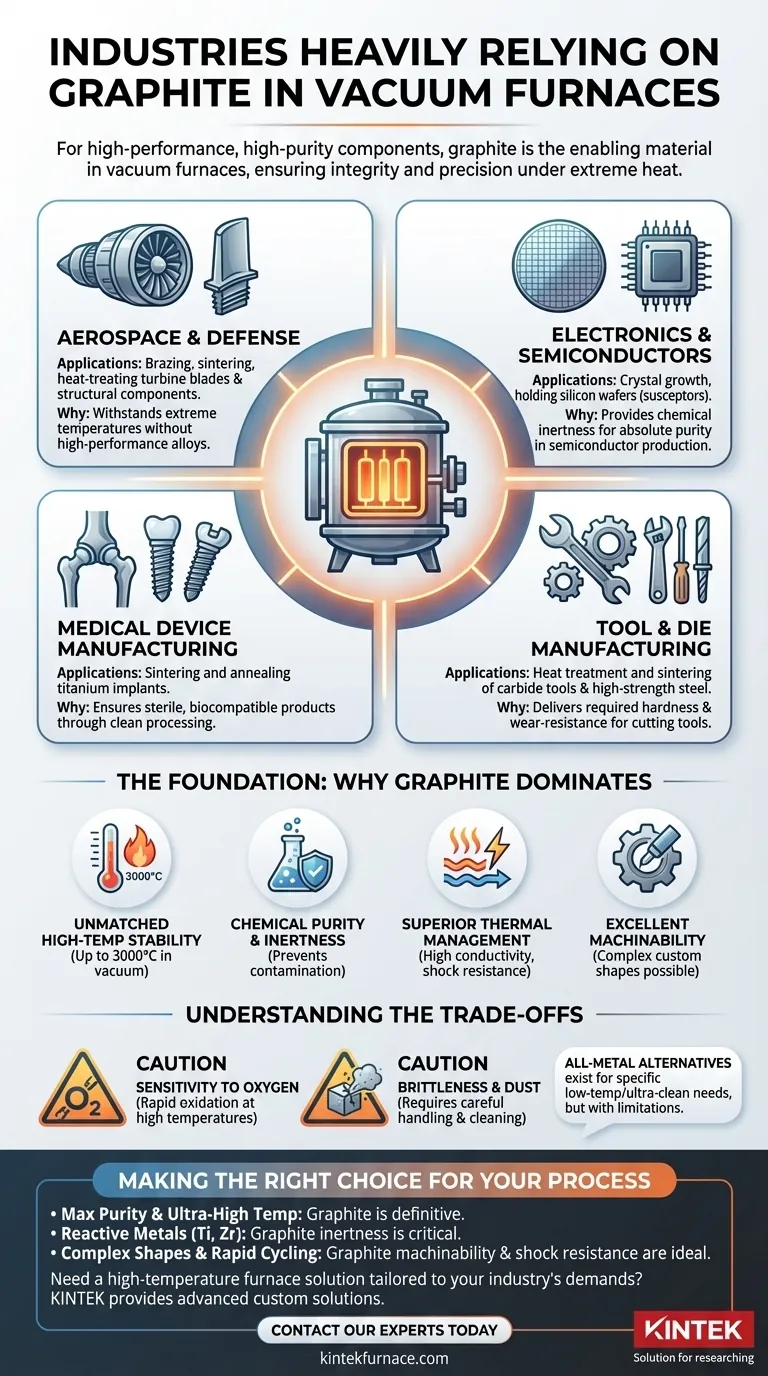

At its core, industries that manufacture high-performance, high-purity components rely heavily on graphite in vacuum furnaces. This includes the aerospace, electronics and semiconductor, medical device, and advanced tool manufacturing sectors, where material integrity and precision under extreme heat are non-negotiable.

The widespread use of graphite in vacuum furnaces is not a matter of preference, but of necessity. Its unique ability to withstand extreme temperatures without deforming or contaminating the product makes it the enabling material for creating the world's most advanced components.

The Foundation: Why Graphite Dominates in Vacuum Environments

Graphite's role extends far beyond simply getting hot. It serves as the furnace's very heart, acting as heating elements, structural fixtures, insulation, and containers for the workpieces themselves. Several key properties make it indispensable.

Unmatched High-Temperature Stability

Graphite is one of the few materials that maintains its structural strength at extreme temperatures, capable of operating up to 3000°C (5432°F) in a vacuum or inert gas.

Unlike metals that would melt or deform, graphite gets stronger as it gets hotter, ensuring the furnace's internal components remain stable during critical processes.

Chemical Purity and Inertness

In a vacuum furnace, preventing contamination is paramount. Graphite is naturally inert and has extremely high purity, meaning it will not react with or release impurities into the materials being processed.

This is critical for applications like growing semiconductor crystals or heat-treating medical implants, where even microscopic contamination can cause catastrophic failure.

Superior Thermal Management

Graphite possesses a unique combination of thermal properties. Its high thermal and electrical conductivity makes it an efficient and responsive heating element.

Simultaneously, its exceptional resistance to thermal shock allows it to endure the rapid heating and cooling cycles (quenching) common in heat treating without cracking or failing.

Excellent Machinability

Despite its strength, graphite is relatively easy to machine. This allows for the creation of complex and precise components like custom-shaped heating elements, intricate workpiece fixtures, and holders.

This versatility ensures that a furnace's internal setup can be tailored to the exact needs of the product being manufactured.

Key Industrial Applications Driven by Graphite

The properties of graphite directly enable critical processes in several high-stakes industries.

Aerospace and Defense

This sector requires components made from high-performance alloys and composites that can withstand incredible stress.

Processes like brazing, sintering, and heat-treating turbine blades or structural components are performed in graphite-lined vacuum furnaces to achieve the required strength and fatigue resistance without introducing impurities.

Electronics and Semiconductors

The production of silicon wafers and integrated circuits demands an environment of absolute purity.

Graphite is used to create fixtures (susceptors) that hold silicon wafers and as heating elements for crystal growth processes. Its inertness ensures the electronic properties of the semiconductor are not compromised.

Medical Device Manufacturing

The production of medical implants, such as titanium hip joints or dental screws, requires clean, high-temperature processing to ensure biocompatibility.

Vacuum furnaces with graphite internals are used for sintering and annealing these parts, creating a strong, sterile product that the human body will not reject.

Tool and Die Manufacturing

High-strength steel and carbide tools used in cutting and forming operations must be incredibly hard and wear-resistant.

Graphite furnaces are essential for the heat treatment and sintering processes that give these tools their required hardness and durability.

Understanding the Trade-offs

While graphite is dominant, it is not without its operational considerations. Acknowledging these is key to its successful implementation.

Sensitivity to Oxygen

Graphite's high-temperature strength is entirely dependent on a vacuum or inert gas environment. If oxygen is introduced at high temperatures, the graphite will rapidly oxidize and degrade, compromising the furnace and the product.

Maintaining the integrity of the vacuum is the single most critical operational factor when using a graphite hot zone.

Brittleness and Dust

At room temperature, graphite can be brittle and must be handled with care to avoid chipping or cracking.

Furthermore, graphite dust can be a source of particulate contamination if not properly managed during maintenance and cleaning cycles.

All-Metal Alternatives

For certain applications, particularly at lower temperatures or where extreme cleanliness is needed (to the point that even graphite dust is a concern), all-metal hot zones using materials like molybdenum or tungsten exist as an alternative.

However, these metals are typically more expensive, have lower maximum operating temperatures, and can become brittle after repeated heating cycles.

Making the Right Choice for Your Process

Your specific manufacturing goal will determine how you leverage graphite's capabilities.

- If your primary focus is maximum purity and ultra-high temperatures: Graphite is the definitive choice, particularly for semiconductor, solar, and advanced materials research.

- If your primary focus is processing reactive metals: The inert nature of graphite is critical for heat-treating materials like titanium and zirconium without creating unwanted chemical reactions.

- If your primary focus is complex part shapes and rapid cycling: Graphite's excellent machinability and resistance to thermal shock make it ideal for creating custom fixtures used in high-volume heat-treating operations.

Ultimately, graphite's unique combination of thermal and chemical properties makes it the foundational material for the most demanding and innovative manufacturing processes on earth.

Summary Table:

| Industry | Key Applications | Why Graphite is Essential |

|---|---|---|

| Aerospace & Defense | Brazing, sintering, heat-treating turbine blades & structural components | Withstands extreme temperatures without contaminating high-performance alloys |

| Electronics & Semiconductors | Crystal growth, holding silicon wafers (susceptors) | Provides chemical inertness for absolute purity in semiconductor production |

| Medical Device Manufacturing | Sintering and annealing titanium implants (hips, dental screws) | Ensures sterile, biocompatible products through clean processing |

| Tool & Die Manufacturing | Heat treatment and sintering of carbide tools and high-strength steel | Delivers the hardness and wear-resistance required for cutting tools |

Need a high-temperature furnace solution tailored to your industry's purity and performance demands?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements.

Whether you are in aerospace, semiconductors, medical devices, or tool manufacturing, we can design a furnace with a graphite hot zone optimized for your specific process. Contact our experts today to discuss how our solutions can enhance your material integrity and manufacturing precision.

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- Why is graphite a preferred material for heating elements in high-temperature vacuum furnaces?

- Why is graphite cost-effective for vacuum furnaces? Maximize Long-Term ROI & Efficiency

- What is the primary application of vacuum heat treating furnaces in aerospace? Enhance Component Performance with Precision