At its core, furnace brazing is the joining technology of choice for industries where component failure is not an option. It is most commonly used in the aerospace, automotive, medical, electronics, and tool and die sectors for creating strong, reliable, and complex assemblies. The process is essential for manufacturing everything from jet engine turbine blades to critical medical implants.

The widespread adoption of furnace brazing is not accidental. It is the definitive solution for applications demanding high-strength, clean, and often hermetically sealed joints, especially when joining complex shapes or dissimilar materials that cannot be reliably welded.

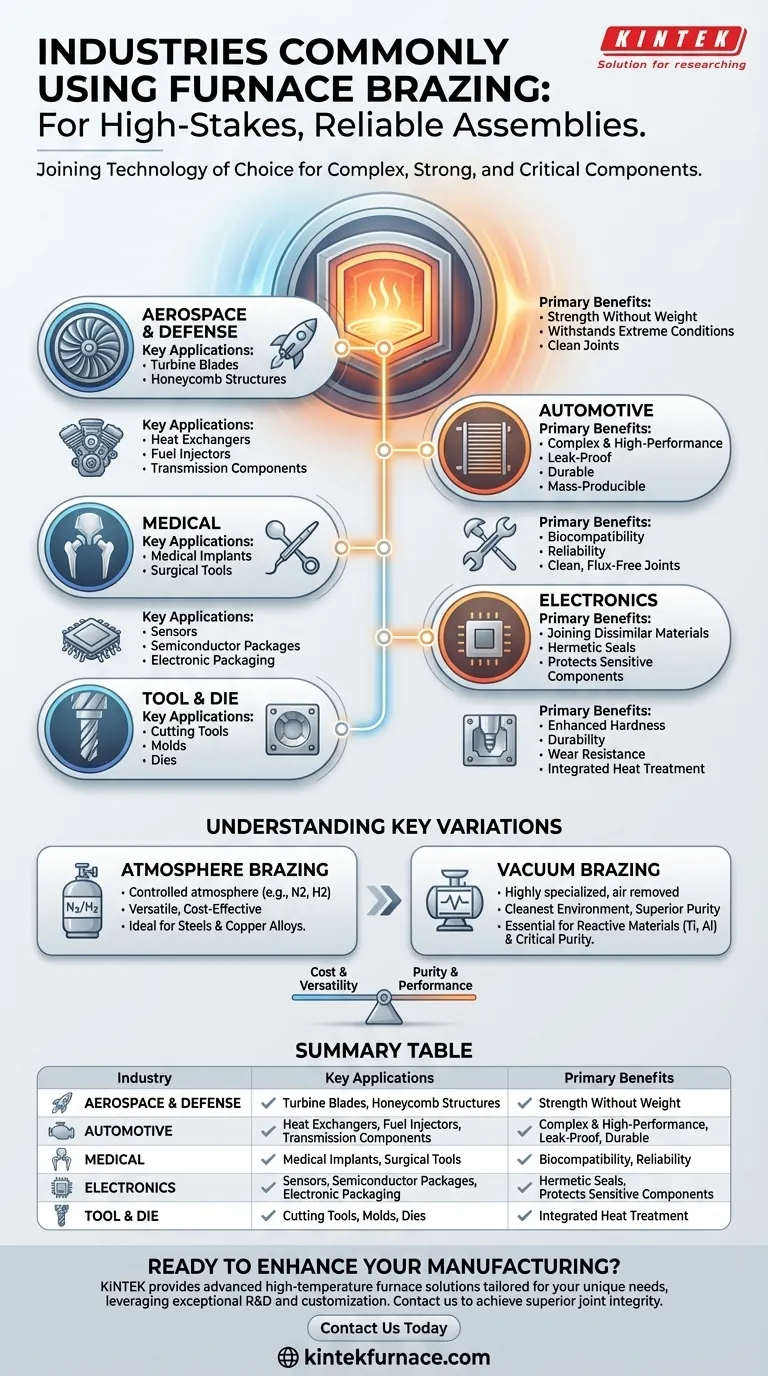

Why These Industries Rely on Furnace Brazing

Furnace brazing solves specific, high-stakes engineering challenges that are common in advanced manufacturing. The controlled heating and cooling environment allows for the creation of stress-free joints with exceptional integrity.

Aerospace and Defense: For Strength Without Weight

In aerospace, every gram matters, but so does structural integrity. Furnace brazing, particularly vacuum brazing, is used to create lightweight yet incredibly strong components.

This process allows for the joining of thin-walled sections and complex assemblies, such as turbine blades and honeycomb structures, without distorting or weakening the base materials. The resulting joints are clean, strong, and can withstand extreme temperatures and vibrations.

Automotive: For Complex and High-Performance Parts

The automotive industry uses furnace brazing to mass-produce complex assemblies that must be durable and leak-proof.

Key applications include heat exchangers, fuel injectors, and transmission components. The ability of the filler metal to flow into tight joints via capillary action makes it perfect for creating the intricate pathways required in these parts.

Medical: For Biocompatibility and Reliability

When a component is implanted in the human body, its material purity and joint integrity are paramount. Vacuum furnace brazing is the standard for many medical devices.

The process creates exceptionally clean, flux-free joints, preventing any contaminants from leaching into the body. This is critical for manufacturing medical implants and surgical tools where biocompatibility and absolute reliability are non-negotiable.

Electronics: For Joining Dissimilar Materials

The electronics industry often needs to join metals to non-metals, like ceramics, which have very different thermal expansion rates. Furnace brazing excels at this.

It is used to produce sensors, semiconductor packages, and other electronic packaging. By carefully controlling the heating and cooling cycle, the process creates a strong, hermetic seal between materials like ceramic and copper, protecting sensitive electronics.

Tool and Die: For Hardness and Durability

In the tool and die industry, the lifespan of a tool is directly tied to its hardness and wear resistance.

Furnace brazing is used to attach super-hard materials like tungsten carbide to steel shanks for cutting tools, molds, and dies. The process not only joins the materials but can also be integrated with heat treatment to enhance the overall hardness and durability of the finished tool.

Understanding the Key Variations

While often discussed as a single process, the environment inside the furnace creates a critical distinction. The choice between an active atmosphere or a vacuum dictates the final properties of the joint.

Atmosphere Brazing

This is the most common form, where the furnace is filled with a controlled atmosphere (like nitrogen, hydrogen, or a mix) to prevent oxidation. It is a robust and cost-effective method suitable for a wide range of materials, particularly steels and copper alloys.

Vacuum Brazing

In this highly specialized process, nearly all air and gases are removed from the furnace chamber, creating a vacuum. This is the cleanest possible environment for brazing.

Vacuum brazing is essential for joining reactive materials like titanium and aluminum or for applications demanding the highest purity, such as in the aerospace and medical fields. It produces bright, clean parts with no need for post-braze cleaning.

The Core Trade-off: Cost vs. Purity

The choice is a classic engineering trade-off. Atmosphere brazing is a versatile workhorse for many industrial applications. Vacuum brazing provides superior cleanliness and performance for mission-critical parts but comes at a higher equipment and processing cost.

Making the Right Choice for Your Goal

To determine if furnace brazing fits your project, consider the primary requirement of the component's joint.

- If your primary focus is high-strength, lightweight components: Furnace brazing is ideal, particularly the vacuum process used extensively in aerospace.

- If your primary focus is joining dissimilar materials like ceramics and metals: This process is a leading solution, crucial for creating hermetic seals in electronics.

- If your primary focus is creating complex, leak-proof assemblies: Furnace brazing excels at joining intricate parts like those found in automotive heat exchangers.

- If your primary focus is biocompatibility and absolute joint integrity: Vacuum furnace brazing is the standard for critical medical implants where purity is essential.

Ultimately, furnace brazing is the enabling technology that makes many of modern engineering's most advanced products possible.

Summary Table:

| Industry | Key Applications | Primary Benefits |

|---|---|---|

| Aerospace | Turbine blades, honeycomb structures | Lightweight, high-strength, withstands extreme conditions |

| Automotive | Heat exchangers, fuel injectors | Leak-proof, durable, mass-producible |

| Medical | Implants, surgical tools | Biocompatible, clean, flux-free joints |

| Electronics | Sensors, semiconductor packages | Joins dissimilar materials, hermetic seals |

| Tool and Die | Cutting tools, molds, dies | Enhanced hardness, durability, wear resistance |

Ready to enhance your manufacturing with reliable furnace brazing solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, automotive, medical, electronics, and tool and die. Our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how we can help you achieve superior joint integrity and efficiency in your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control