At their core, vacuum furnace temperature control systems are categorized by their logic and interface: PID (Proportional-Integral-Derivative) programmable control, which is the foundational logic for precision, and PLC (Programmable Logic Controller) full-automatic control for complex, integrated automation. These systems are often managed through modern touch screen interfaces (HMI). They function by using sensors like thermocouples to continuously feed data to the controller, which then adjusts the power to the heating elements to execute a precise thermal cycle.

The specific type of controller—whether a basic PID or a complex PLC—is less important than its ability to guarantee two outcomes: absolute temperature uniformity across the entire part and perfect cycle-to-cycle repeatability. The control system is what ensures the metallurgical process is scientifically sound and reliable.

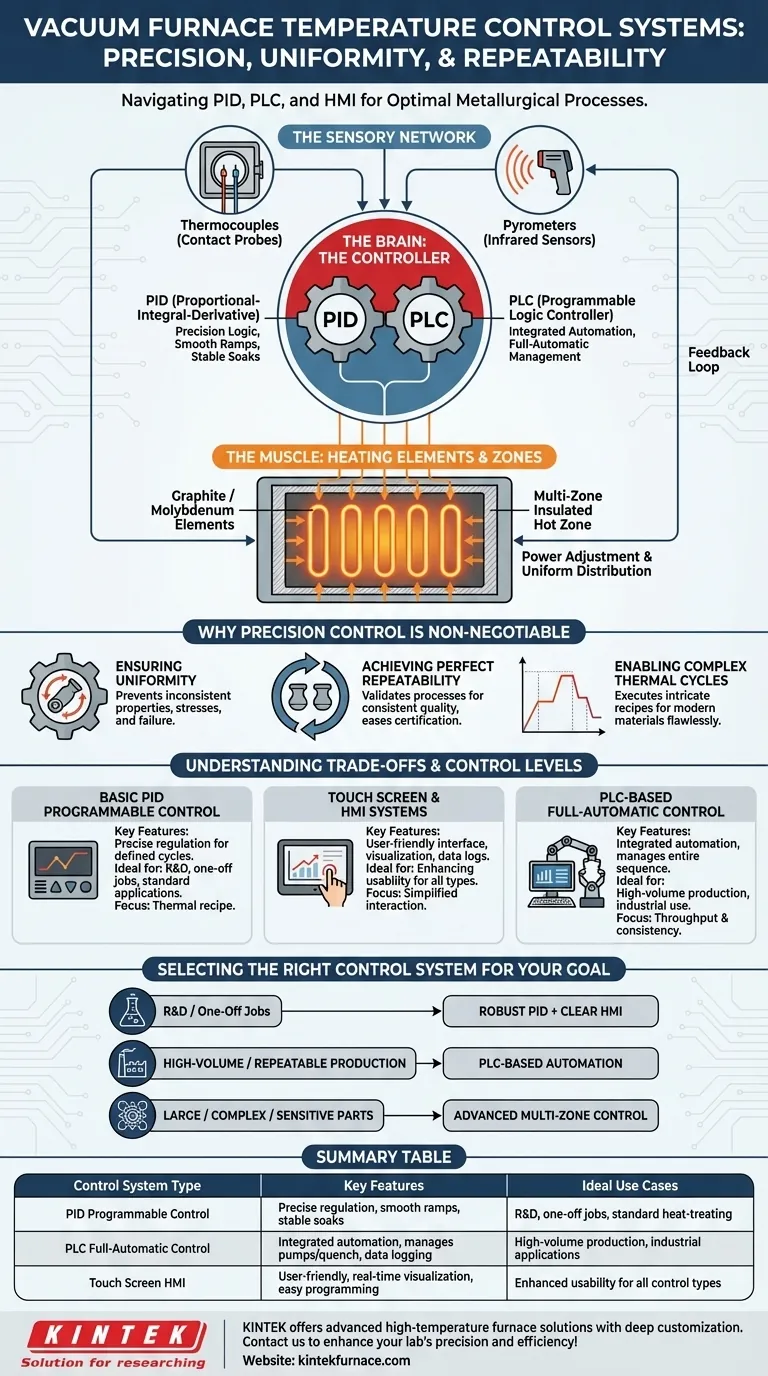

The Anatomy of a Vacuum Furnace Control System

To understand how these systems deliver precision, it's best to break them down into their core functional components. Each part plays a distinct role in the feedback loop that governs the furnace environment.

The Sensory Network: Thermocouples and Pyrometers

The system's ability to control temperature starts with its ability to measure it accurately.

Thermocouples are the most common sensors. They are physical probes placed within the furnace chamber, often in multiple locations, to get a direct contact reading of the workload and hot zone temperature.

Pyrometers, or infrared sensors, measure temperature from a distance by detecting thermal radiation. They are crucial for extremely high-temperature applications where a thermocouple might degrade or be impractical to place.

The Brain: The Controller (PID vs. PLC)

The controller is the decision-making center that processes sensor data and dictates the furnace's action.

A PID controller is the standard for temperature regulation. It uses a sophisticated algorithm to not only react to temperature deviations but to anticipate and prevent them, minimizing overshoot and undershoot. This is what enables smooth ramps and stable soaks.

A PLC is a more powerful, industrial-grade computer. While it uses PID logic for temperature, its primary advantage is its ability to manage the entire furnace sequence—controlling vacuum pumps, gas quench systems, and mechanical movements—making it the foundation of a "full-automatic" system.

The Muscle: Heating Elements and Zones

The controller directs the heating elements, which are typically made of graphite or molybdenum. These elements convert electrical energy into radiant heat.

Sophisticated furnaces divide the hot zone into multiple insulated heating zones. Each zone can be controlled independently, allowing the system to direct more or less power to specific areas to compensate for heat loss and ensure the entire workload maintains a uniform temperature.

Why Precision Control is Non-Negotiable

A vacuum furnace is not simply an oven; it is a precision instrument. The control system is what enables it to perform complex metallurgical processes like hardening, annealing, brazing, and sintering.

Ensuring Uniformity Across the Workload

Without precise, multi-zone control, temperature gradients can form across a part. This means one section could be hotter or cooler than another, leading to inconsistent material properties, internal stresses, and potential part failure.

Achieving Perfect Repeatability

For industries like aerospace and medical manufacturing, processes must be validated and perfectly repeatable. A high-fidelity control system executes the exact same thermal recipe—heating ramps, soak times, and cooling rates—every single time, ensuring consistent quality and simplifying certification.

Enabling Complex Thermal Cycles

Modern material treatments require complex thermal profiles. Processes like precipitation hardening or multi-stage tempering involve several distinct temperature steps. Only a programmable, responsive control system can execute these intricate recipes flawlessly.

Understanding the Trade-offs and Control Levels

Choosing a system involves balancing capability with complexity and cost. Each control level is suited for different operational needs.

Basic PID Programmable Control

This is the workhorse for many standard heat-treating applications. It offers excellent temperature precision for defined cycles. Its primary focus is on the thermal recipe itself, with less integration for other furnace functions.

Touch Screen and HMI Systems

An HMI (Human-Machine Interface) is a user-friendly graphical layer, often a touch screen, built on top of a PID or PLC. Its value is in simplifying programming, visualizing the process in real-time, and easily accessing data logs. It improves usability but doesn't inherently change the underlying control logic.

PLC-Based Full-Automatic Control

This is the top tier for industrial production. A PLC can orchestrate every aspect of the furnace operation, from opening the door and pumping down the vacuum to running the thermal cycle and executing a rapid gas quench. This level of automation reduces operator error and maximizes throughput, but comes with higher initial cost and programming complexity.

Selecting the Right Control System for Your Goal

The best system is the one that reliably achieves your specific process goals.

- If your primary focus is research, development, or one-off jobs: A robust PID controller with a clear user interface for easy programming is often the most practical and cost-effective choice.

- If your primary focus is high-volume, repeatable production: A PLC-based system is essential for its automation capabilities, data logging for quality control, and integration into a production line.

- If your primary focus is processing large, complex, or highly sensitive parts: Prioritize a system with advanced multi-zone control to guarantee temperature uniformity, regardless of whether it is PID or PLC based.

Ultimately, the right control system transforms a vacuum furnace from a simple oven into a precise instrument for materials engineering.

Summary Table:

| Control System Type | Key Features | Ideal Use Cases |

|---|---|---|

| PID Programmable Control | Precise temperature regulation, smooth ramps, stable soaks | R&D, one-off jobs, standard heat-treating |

| PLC Full-Automatic Control | Integrated automation, manages vacuum pumps, gas quench, data logging | High-volume production, industrial applications |

| Touch Screen HMI | User-friendly interface, real-time visualization, easy programming | Enhanced usability for all control types |

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your lab's precision and efficiency with tailored temperature control systems!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What is the role of a muffle furnace in synthesizing P2-Na0.67Ni0.33Mn0.67O2? Key to High-Performance Cathodes

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the function of a muffle furnace in LSCF modification? Achieve Precise Thermal Foundation for Advanced Ceramics