In an electric rotary kiln, the heat is generated by specific resistance heating elements chosen for their temperature capabilities and durability. The most common types are metallic alloys, such as nickel-chromium (NiCr) and iron-chromium-aluminum (FeCrAl), and non-metallic elements like silicon carbide (SiC) rods. For very high-temperature applications, molybdenum disilicide (MoSi2) elements are also used.

The selection of a heating element is not a minor detail; it is the defining factor that dictates the kiln's maximum operating temperature, control strategy, and overall operational cost. Your choice must be driven by the specific thermal requirements of your process.

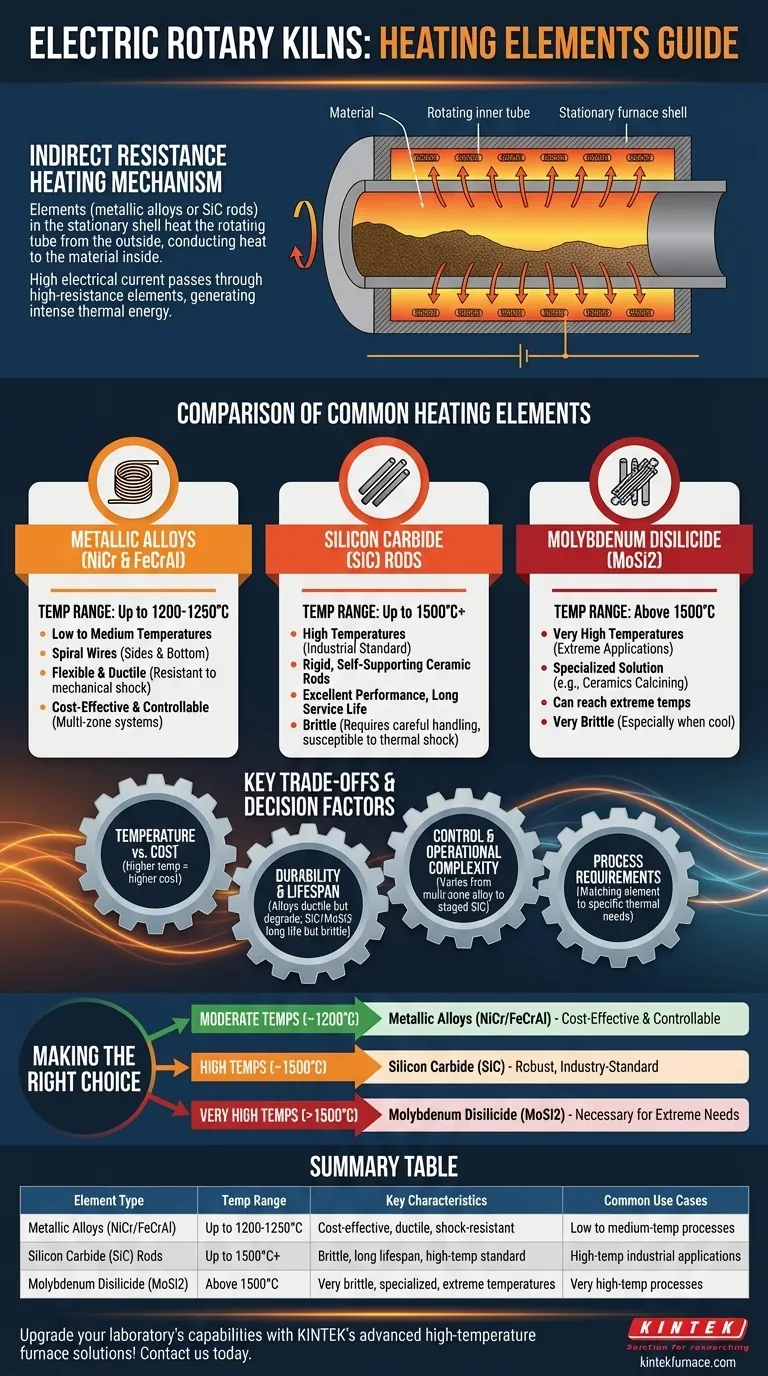

The Anatomy of Electric Heating in Rotary Kilns

To understand the elements, we must first understand how they are applied. The design of an electric rotary kiln fundamentally differs from a direct-fired gas kiln.

Indirect Heating is the Standard

In virtually all electric rotary kilns, the heating method is indirect. The heating elements do not go inside the rotating tube with the material.

Instead, the elements (whether alloy wires or SiC rods) are mounted in the stationary furnace shell, surrounding the rotating tube. They heat the outside of the tube, and that heat is then conducted through the tube wall to the material tumbling inside.

How Resistance Heating Works

The principle is simple and effective. A high electrical current is passed through the heating element, which has a high electrical resistance. This resistance causes the element to heat up intensely, radiating thermal energy into the furnace chamber.

A Comparison of Common Heating Elements

Each type of heating element serves a specific temperature range and operational need. They are not interchangeable.

Metallic Alloy Elements (FeCrAl & NiCr)

These are the workhorses for low to medium-temperature processes, typically up to around 1200-1250°C.

They are formed as spiral wires and installed along the sides and bottom of the furnace chamber. Their flexibility and ductility make them resistant to mechanical shock.

Silicon Carbide (SiC) Rods

When higher process temperatures are required (often up to 1500°C or more), silicon carbide rods are the standard choice.

These are rigid, self-supporting ceramic rods that offer excellent performance at high temperatures. They are more brittle than metallic elements and require careful handling.

Molybdenum Disilicide (MoSi2) Elements

For the most demanding, very high-temperature applications (exceeding 1600°C), MoSi2 elements are used.

These elements can reach extreme temperatures but are also very brittle, especially when cool. They are a specialized solution for processes like calcining certain technical ceramics.

Understanding the Key Trade-offs

Choosing an element involves balancing performance, cost, and operational complexity.

Temperature vs. Cost

This is the primary decision factor. The higher the temperature capability of the element, the higher its material and replacement cost.

- FeCrAl/NiCr: Lowest cost, suitable for moderate temperatures.

- SiC: Mid-range cost, the standard for high-temperature industrial use.

- MoSi2: Highest cost, reserved for specialized, very high-temperature needs.

Durability and Lifespan

Metallic alloys are ductile but can sag or degrade over time, especially if pushed to their temperature limits.

SiC and MoSi2 elements have a very long service life if operated correctly but are susceptible to thermal shock (rapid temperature changes) and can be fractured by mechanical impact.

Control and Operational Complexity

The type of element can influence the kiln's temperature control system.

Kilns with alloy wire elements may feature more temperature control zones (e.g., four distinct zones), allowing for a highly tailored temperature profile along the length of the tube.

Systems with SiC rods might use a different control strategy, such as adjusting power by varying the number of energized rods across three stages. This offers robust control but may be less granular than some multi-zone alloy systems.

Making the Right Choice for Your Process

Your decision should be based entirely on the thermal demands of the material you are processing.

- If your primary focus is moderate temperatures (up to ~1200°C): Metallic alloy elements (FeCrAl or NiCr) provide the most cost-effective and controllable solution.

- If your primary focus is high temperatures (up to ~1500°C): Silicon carbide (SiC) rods are the robust, industry-standard choice for reliable performance.

- If your primary focus is very high temperatures (above 1500°C): Molybdenum disilicide (MoSi2) is the necessary choice, despite its higher cost and specialized handling requirements.

By matching the heating element to your specific temperature and operational needs, you ensure the efficiency, reliability, and success of your thermal process.

Summary Table:

| Heating Element Type | Temperature Range | Key Characteristics | Common Use Cases |

|---|---|---|---|

| Metallic Alloys (NiCr/FeCrAl) | Up to 1200-1250°C | Cost-effective, ductile, resistant to shock | Low to medium-temperature processes |

| Silicon Carbide (SiC) Rods | Up to 1500°C+ | Brittle, long lifespan, high-temperature standard | High-temperature industrial applications |

| Molybdenum Disilicide (MoSi2) | Above 1500°C | Very brittle, specialized, extreme temperatures | Very high-temperature processes like ceramics calcining |

Upgrade your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with tailored electric rotary kilns and other systems like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures precise alignment with your unique experimental needs, boosting efficiency and reliability. Contact us today to discuss how we can optimize your thermal processes!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- Why is a Rotary Kiln specifically suitable for treating high-carbon FMDS? Turn Waste Carbon into a Resource

- What advantages do electrically heated rotary kilns offer in temperature control? Achieve Precision and Uniformity for Superior Results

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency