In dental technology, a press furnace is purpose-built for one primary task: fabricating restorations from pressable glass-ceramics. These furnaces use a combination of precise heat and pneumatic pressure to create restorations known for their exceptional accuracy, strength, and aesthetics. The most common material used in this process is lithium disilicate.

A press furnace is not a universal oven; it is a specialized tool designed for the "lost-wax" technique using pressable ceramics. Understanding this distinction is crucial because materials like zirconia require a completely different process—sintering—which press furnaces cannot perform.

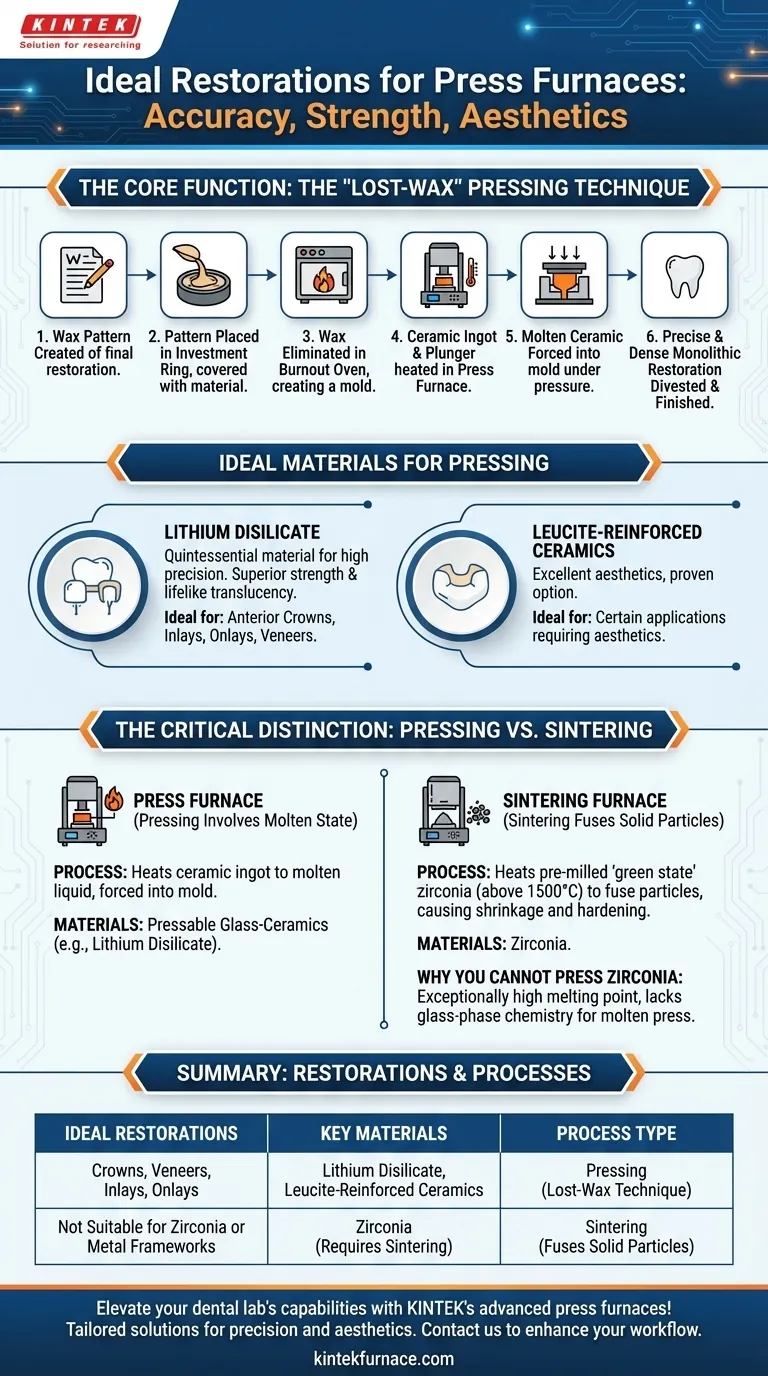

The Core Function: How a Press Furnace Works

A press furnace executes a specific, multi-stage process that differs significantly from other types of dental furnaces. Its function is tied directly to the properties of pressable glass-ceramics.

The "Lost-Wax" Pressing Technique

The process begins with a wax pattern of the final restoration. This wax-up is placed in a special investment ring and covered with a plaster-like investment material.

Once the investment hardens, the ring is placed in a separate burnout oven (not the press furnace itself) to melt and eliminate the wax, leaving a detailed negative mold of the restoration.

Applying Heat and Pressure

The investment ring, now containing the empty mold, is heated to a precise temperature inside the press furnace. A ceramic ingot (e.g., lithium disilicate) is placed into the ring.

The furnace then uses a pneumatic plunger to press the now-molten, viscous ceramic into the void left by the wax. The combination of exact temperature control and consistent pressure ensures the material flows into every detail of the mold.

The Result: A Precise and Dense Restoration

This method produces a monolithic restoration that is incredibly dense, strong, and accurately fits the prepared tooth. The final restoration is then divested from the investment material, finished, and polished.

Ideal Materials for Pressing

Press furnaces are designed exclusively for materials that can be heated to a viscous state and pressed into a mold without degrading.

Lithium Disilicate

This is the quintessential material for press technology. Its glass-ceramic composition allows it to be pressed with high precision, resulting in restorations that offer a superior blend of strength and lifelike translucency, ideal for anterior crowns, inlays, onlays, and veneers.

Leucite-Reinforced Ceramics

Other glass-ceramics, such as those reinforced with leucite, are also designed for pressing. While often not as strong as lithium disilicate, they offer excellent aesthetics and are a proven option for certain applications.

The Critical Distinction: Pressing vs. Sintering

A common point of confusion is the difference between a press furnace and a sintering furnace. They perform fundamentally different thermal processes and are not interchangeable.

Pressing Involves a Molten State

As detailed above, pressing works by heating a ceramic ingot until it becomes a thick, molten liquid, which is then forced into a mold.

Sintering Fuses Solid Particles

A sintering furnace is used for materials like zirconia. Zirconia restorations are first milled from a pre-sintered, chalk-like block.

These "green state" restorations are then placed in a sintering furnace and heated to extremely high temperatures (often above 1500°C) for several hours. This process does not melt the zirconia; instead, it fuses the particles together, causing the restoration to shrink and harden into its final, incredibly strong state.

Why You Cannot Press Zirconia

Zirconia has an exceptionally high melting point and does not have the glass-phase chemistry required for a controlled molten press. A dental press furnace cannot reach the required temperatures or manage the material properties of zirconia for a pressing process.

Understanding the Trade-offs

Choosing to integrate a press furnace into a workflow comes with clear benefits and limitations.

Benefit: Unmatched Fit and Aesthetics

For single-unit crowns, veneers, inlays, and onlays, pressed ceramics provide some of the best marginal fit and natural aesthetics available in dentistry. The monolithic structure avoids issues with chipping that can sometimes occur with layered porcelain.

Limitation: Material Constraints

A press furnace is a one-trick pony. It excels at its job but can only be used with pressable ceramic ingots. It cannot be used for zirconia, metal frameworks, or stacking conventional porcelains.

Limitation: Labor and Technique Sensitivity

The lost-wax technique is a manual, skill-dependent process. It involves more steps (waxing, investing, burnout, pressing, divesting) than a digital "mill and sinter" workflow for zirconia, making it more time-consuming.

Making the Right Choice for Your Lab

Your decision should be driven entirely by the types of restorations you plan to produce.

- If your primary focus is high-aesthetic single crowns, veneers, inlays, and onlays: A press furnace is an essential tool for working with materials like lithium disilicate.

- If your primary focus is high-strength multi-unit bridges and full-arch frameworks: A sintering furnace for processing zirconia is the non-negotiable requirement.

- If your primary focus is maximum versatility for a full-service lab: You will need both a press furnace for glass-ceramic restorations and a sintering furnace for zirconia-based restorations.

Ultimately, matching the furnace technology to the material's scientific properties is the key to achieving predictable, high-quality clinical outcomes.

Summary Table:

| Ideal Restorations | Key Materials | Process Type |

|---|---|---|

| Crowns, Veneers, Inlays, Onlays | Lithium Disilicate, Leucite-Reinforced Ceramics | Pressing (Lost-Wax Technique) |

| Not Suitable for Zirconia or Metal Frameworks | Zirconia (Requires Sintering) | Sintering (Fuses Solid Particles) |

Elevate your dental lab's capabilities with KINTEK's advanced press furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace solutions tailored for precision and aesthetics. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization to meet your unique experimental needs. Whether you're crafting crowns, veneers, or other restorations, our press furnaces ensure superior fit and strength. Contact us today to discuss how we can enhance your workflow and deliver exceptional results for your target customers in dental technology!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique