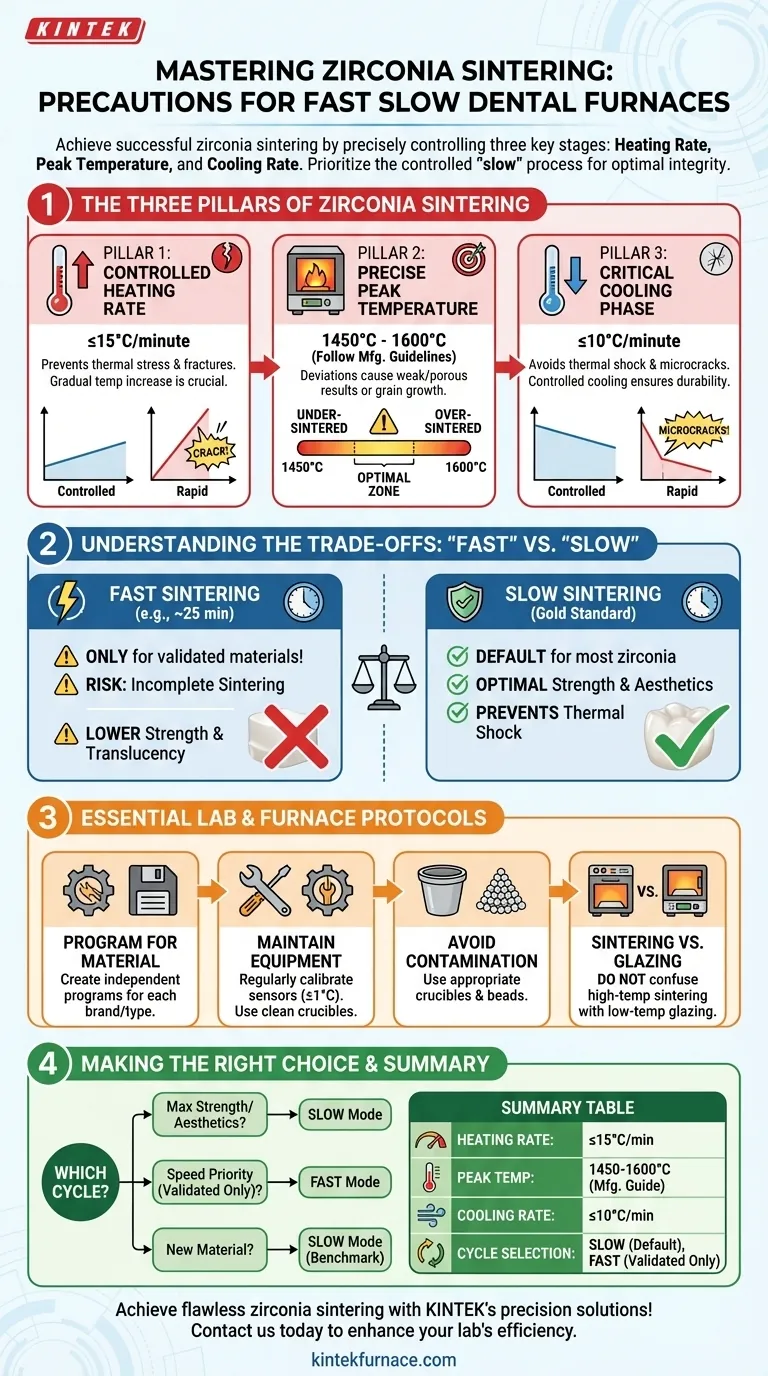

To ensure successful zirconia sintering, you must precisely control three key stages: the heating rate, the peak temperature, and the cooling rate. The most critical precautions are maintaining a slow heating rate (under 15°C/minute) to prevent fractures, adjusting the peak temperature (between 1450°C and 1600°C) to match the specific zirconia manufacturer's guidelines, and ensuring an even slower cooling rate (under 10°C/minute) to avoid thermal shock and microcracks.

The dual-mode "Fast Slow" furnace offers flexibility, but the fundamental properties of zirconia dictate the process. True mastery lies not in using the "fast" setting by default, but in understanding when the material's integrity requires the deliberate, controlled "slow" process.

The Three Pillars of Zirconia Sintering

Sintering is a process of transformation, and any rush or deviation can compromise the final result. Adhering to these three pillars is non-negotiable for achieving restorations with optimal strength and aesthetics.

Pillar 1: The Controlled Heating Rate

The initial heating phase is where the restoration is most vulnerable to thermal stress. A rapid increase in temperature creates a significant differential between the surface and the core of the zirconia.

This stress can easily lead to cracks, especially in thicker restorations or multi-unit bridges. A recommended maximum heating rate of ≤15°C per minute allows the temperature to distribute evenly, preventing internal stress buildup.

Pillar 2: The Precise Peak Temperature

There is no universal sintering temperature for all zirconia. Each brand and type (e.g., high-strength vs. high-translucency) has a specific peak temperature specified by the manufacturer, typically falling within the 1450°C to 1600°C range.

Deviating from this precise target can have significant consequences. Under-sintering results in a weak, porous restoration, while over-sintering can cause grain growth that reduces strength and negatively impacts translucency and color.

Pillar 3: The Critical Cooling Phase

The cooling phase is just as critical as the heating phase. As zirconia cools, it undergoes a phase transformation that involves a slight change in volume.

If cooling occurs too quickly, it introduces thermal shock, leading to microcracks that compromise the long-term structural integrity of the restoration. A controlled cooling rate of ≤10°C per minute is essential to prevent this and ensure maximum durability.

Understanding the Trade-offs: "Fast" vs. "Slow"

A dual-mode furnace presents a choice between speed and precision. Understanding the implications of each mode is key to avoiding costly failures.

When to Use Fast Sintering (and its Risks)

The "fast" cycle, which can be as short as 25 minutes, is exclusively designed for specific zirconia materials explicitly validated for rapid sintering.

Using this mode with standard zirconia is a significant risk. It can lead to incomplete sintering, lower final strength, and reduced translucency. Always verify with the material manufacturer before attempting a fast cycle.

Why Slow Sintering Remains the Gold Standard

The "slow" mode is the default, safe, and recommended method for the vast majority of zirconia materials. It adheres to the controlled heating and cooling rates required for optimal results.

For highly aesthetic ceramics, particularly those with a glass phase component, slow sintering ensures even heat distribution and prevents material flow issues, resulting in superior translucency and consistent color.

Essential Furnace and Lab Protocols

Beyond the sintering cycle itself, consistent results depend on rigorous lab protocols and equipment maintenance.

Program for the Material

Never use a single, generic program for different materials. Create and save independent sintering programs for each specific brand and type of zirconia you use. This prevents catastrophic errors from using the wrong parameters.

Maintain Your Equipment

The furnace's accuracy is paramount. Ensure regular calibration of temperature sensors and heating elements to maintain the required precision of ±1°C. Use clean, appropriate crucibles and sintering beads to avoid contaminating the restorations.

Clarifying Sintering vs. Glazing

Do not confuse a low-temperature glazing cycle with a high-temperature sintering cycle. Programs running at 800-900°C are for applying a final glaze, not for sintering the core zirconia material. Mixing these up will result in a complete failure.

Making the Right Choice for Your Restoration

Your choice of sintering cycle should be driven by the clinical demands of the case and the specific material you are using.

- If your primary focus is maximum strength and aesthetics (e.g., anterior cases, bridges): Always use the slow sintering mode and strictly follow the zirconia manufacturer's protocol.

- If your primary focus is speed for a single, non-critical restoration: Use the fast mode only if the specific zirconia you are using is explicitly validated by the manufacturer for that cycle.

- If you are sintering a new type of zirconia for the first time: Always begin with the manufacturer's recommended slow-sintering program to establish a benchmark for quality and performance.

By treating the furnace as a precision instrument rather than an appliance, you will produce predictable, high-quality results every time.

Summary Table:

| Precautions | Key Details |

|---|---|

| Heating Rate | ≤15°C/minute to prevent fractures |

| Peak Temperature | 1450°C to 1600°C, follow manufacturer guidelines |

| Cooling Rate | ≤10°C/minute to avoid microcracks |

| Cycle Selection | Use slow mode for most zirconia; fast only if validated |

| Equipment Maintenance | Regular calibration and clean crucibles for accuracy |

Achieve flawless zirconia sintering with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide dental laboratories with advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental needs are met precisely. Contact us today to enhance your lab's efficiency and quality!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations