From a purely operational standpoint, electric rotary kilns offer three primary advantages over traditional fuel-fired systems. They deliver simplified process management by eliminating the need for fuel handling, provide exceptionally precise temperature control essential for sensitive materials, and often result in more economical operation due to superior thermal efficiency.

The core benefit of an electric rotary kiln is not merely a different heat source, but a fundamental shift towards digital process control. This allows for unprecedented levels of precision, repeatability, and efficiency that are difficult to achieve with combustion-based systems.

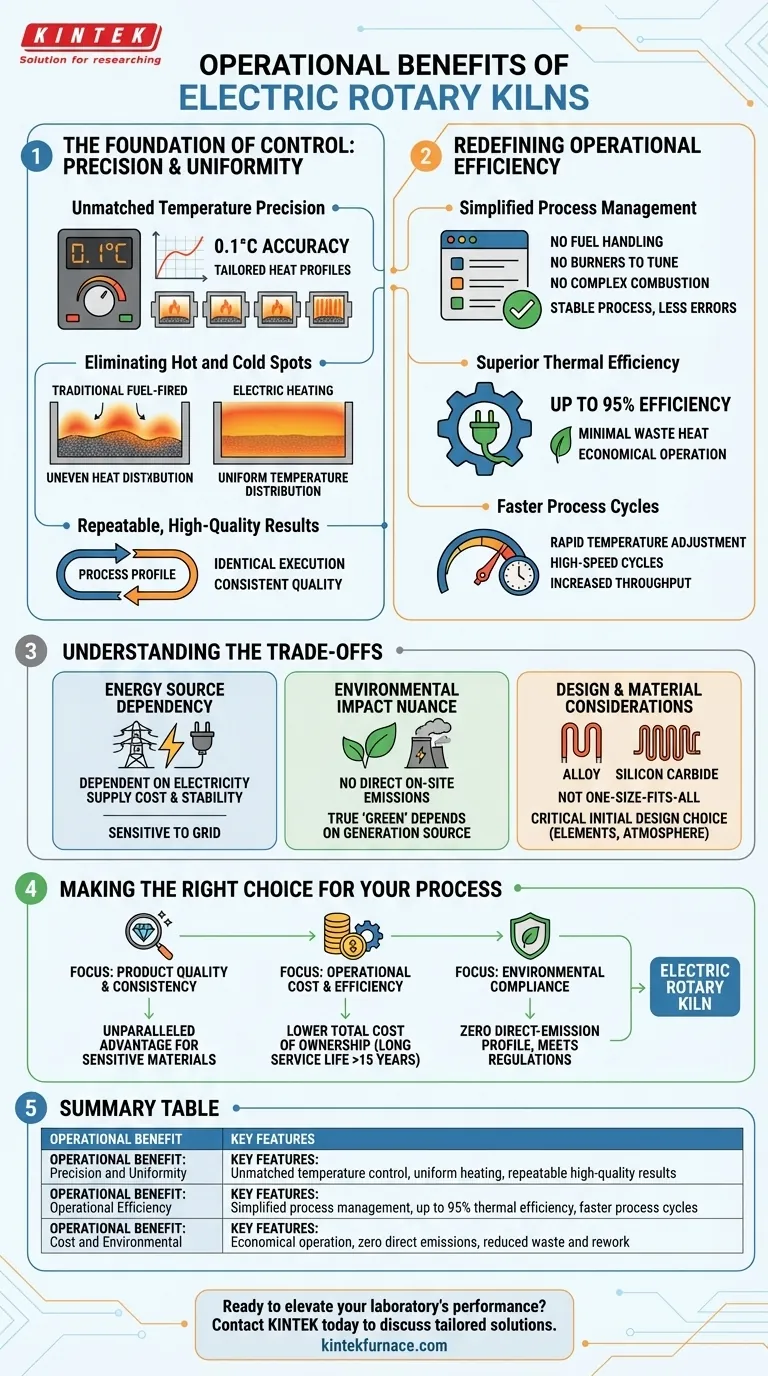

The Foundation of Control: Precision and Uniformity

The primary operational advantage of electric heating is the degree of control it provides. This control directly translates into higher, more consistent product quality.

Unmatched Temperature Precision

Electric systems allow for extremely precise temperature management across the entire operational range. This is especially true at lower temperatures, where gas-fired kilns can struggle with control and stability.

This precision is managed through sophisticated controls, such as kilns with multiple, separately controllable temperature zones. This allows for a tailored heat profile along the length of the kiln.

Eliminating Hot and Cold Spots

Electric heating promotes highly uniform temperature distribution throughout the material bed. This uniformity ensures that every particle undergoes the same thermal process.

By eliminating the hot and cold spots common in fuel-fired systems, you achieve a more consistent and predictable final product, reducing waste and rework.

Repeatable, High-Quality Results

The combination of precision and uniformity means electric kilns consistently deliver repeatable, high-quality results.

Once a process profile is established, it can be executed identically time and again, which is critical for industries with stringent quality specifications.

Redefining Operational Efficiency

Efficiency in electric kilns extends beyond energy savings to include simplified workflows and faster production cycles.

Simplified Process Management

The most immediate operational change is the elimination of fuel management. There are no burners to tune, no fuel lines to maintain, and no complex combustion chemistry to balance.

This simplification reduces the variables an operator must manage, leading to a more stable and less error-prone process.

Superior Thermal Efficiency

Electric kilns can achieve extremely high thermal efficiency, sometimes up to 95%. The energy is delivered directly to the process with minimal waste heat.

This efficiency is a key driver behind the claim that electric kilns can be more economical to operate than gas or oil-fired alternatives, especially as energy costs fluctuate.

Faster Process Cycles

The ability for rapid temperature adjustment and integration with high-pressure gas quenching allows for high-speed process cycles. This increases throughput without sacrificing product quality.

Understanding the Trade-offs

While the operational benefits are clear, a responsible evaluation requires understanding the associated trade-offs. Electric kilns are a powerful tool, but not a universal solution.

Energy Source Dependency

Your operation becomes entirely dependent on the cost and reliability of your electricity supply. While you gain independence from fossil fuel volatility, you become sensitive to grid stability and electricity pricing structures.

Environmental Impact Nuance

While electric kilns produce no direct, on-site emissions, the overall environmental benefit is tied to how the electricity is generated. The process is only truly "green" if the electricity comes from renewable sources.

Design and Material Considerations

The technology is not one-size-fits-all. Different models use different heating elements, such as alloy or silicon carbide, each with its own temperature limits, atmospheric compatibility, and lifespan. The initial design choice is critical to long-term success.

Making the Right Choice for Your Process

Your specific production goal should be the primary driver in evaluating whether an electric rotary kiln is the right fit for your operation.

- If your primary focus is product quality and consistency: The granular temperature control and uniform heating of an electric kiln offer an unparalleled advantage for sensitive or high-value materials.

- If your primary focus is operational cost and efficiency: The combination of high thermal efficiency, simplified management, and long service life (often over 15 years) presents a strong case for lower total cost of ownership.

- If your primary focus is environmental compliance: The zero direct-emission profile provides a clear path to meeting current and future air quality regulations.

Ultimately, adopting an electric rotary kiln is a strategic decision that trades the familiar challenges of combustion for the precise control of electrification.

Summary Table:

| Operational Benefit | Key Features |

|---|---|

| Precision and Uniformity | Unmatched temperature control, uniform heating, repeatable high-quality results |

| Operational Efficiency | Simplified process management, up to 95% thermal efficiency, faster process cycles |

| Cost and Environmental | Economical operation, zero direct emissions, reduced waste and rework |

Ready to elevate your laboratory's performance with advanced high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with electric rotary kilns, muffle furnaces, tube furnaces, and more. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior precision, efficiency, and reliability. Contact us today to discuss how our tailored solutions can optimize your processes and drive success!

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Kiln for Pyrolysis Plant Heating

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is an electric heating rotary kiln and what industries use it? Discover Precision Heating for High-Purity Materials

- How does the raw meal move inside the rotary kiln? Master Controlled Flow for Efficient Processing

- How does automated control in electric rotary kilns benefit industrial processes? Achieve Unmatched Precision & Efficiency

- What is the basic working principle of a rotary kiln? Master Industrial Thermal Processing Efficiency

- What are the uses of rotary kilns in the building materials industry besides cement clinker? Key Applications Explained